A production process of double-layer co-extruded ultra-low temperature zipper

A technology of double-layer co-extrusion and production process, applied in the field of zipper, can solve the problems of high energy consumption, increase production cost, affect the yield of finished products, etc., and achieve the effects of reducing production cost, lowering production temperature and improving yield of finished products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

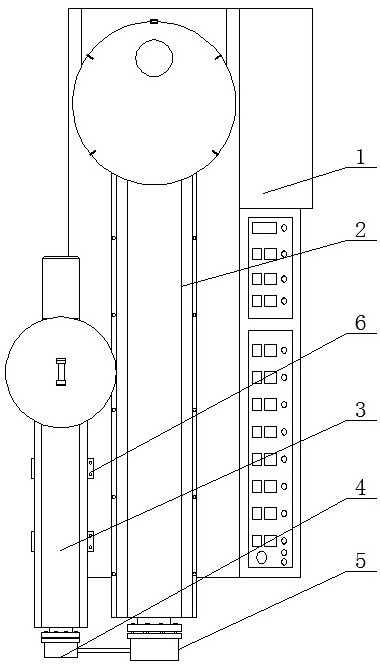

[0046] The prepared raw materials are put into the extruder 2 and co-extrusion machine 3 in the extrusion structure respectively through the silo. After the extruder 2 and the co-extrusion machine 3 are heated and kept warm, the extrusion starts. Through the above-mentioned process flow , to complete the entire production process, in this process, the extruder 2 is responsible for extruding the main body of the clip chain, and the main channel A52 and main channel B54 inside the main mold 5 are respectively responsible for extruding the matching clip chain;

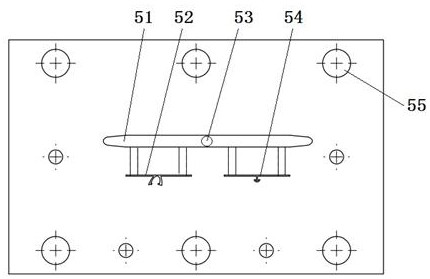

[0047]The auxiliary materials in the co-extrusion machine 3 enter the main mold 5 through the die head 4, and flow into the co-extrusion flow channel 51 through the feed point 53 in the main mold 5. The two ends of the co-extrusion flow channel 51 respectively divide four strands of auxiliary materials into the main flow. Road A52, main channel B54, and the joints between the four branch channels and main channel A52 and m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com