Method for preparing porous adsorption material from oil shale semicoke stable Pickering emulsion

A porous adsorption material, oil shale semi-coke technology, applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal oxides/hydroxides, etc., to achieve good mechanical strength, high adsorption capacity, and good adsorption effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

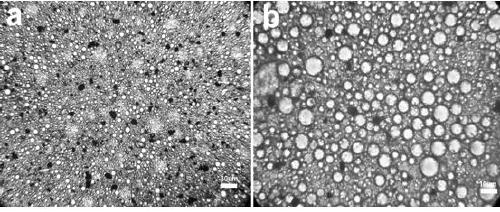

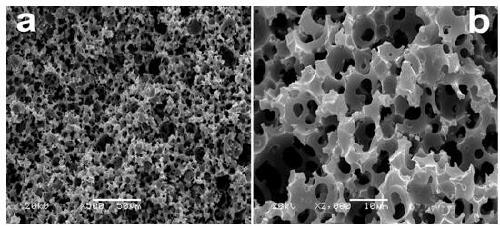

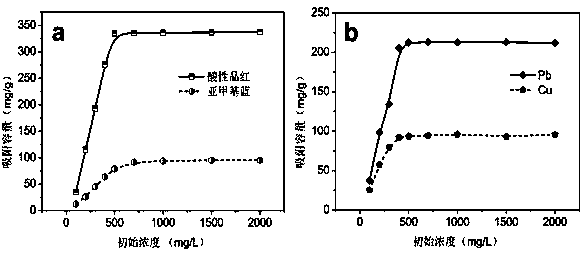

[0030] Example 1

[0031] Crumble the oil shale semi-coke through a 100-mesh sieve; take 1g of oil shale semi-coke powder, and calcinate it in a nitrogen atmosphere at 300°C for 24h; add it into 16 mL of water, and disperse evenly under stirring at 500 rpm; take 10g of 2-propene Amino-2-methylpropanesulfonic acid, 16g Allylthiourea, 3g N,N' -Methylenebisacrylamide, 1g ammonium persulfate, and disperse evenly; then add 53 mL of xylene, stir at 500rpm to form an emulsion, then polymerize at 50°C for 24 h, then extract with acetone Soxhlet for 48 h, at 105°C Drying for 4 hours at the bottom to obtain a porous adsorption material. The porous adsorbent material for heavy metal Pb 2+ The adsorption capacity for the cationic dye methylene blue (MB) was 95.16 mg / g, and the adsorption capacity for the anionic dye acid fuchsin was 202.78 mg / g.

Example Embodiment

[0032] Example 2

[0033] The oil shale semi-coke was crushed through a 600-mesh sieve, and 8 g of oil shale semi-coke powder was calcined at 900 °C for 1 h in a nitrogen atmosphere; it was added to 30 mL of water and dispersed evenly under stirring at 500 rpm; then 22 g styrene, 23 g acrylonitrile, 4 mL cyclohexane, 8 g triallyl isocyanate and 5 g benzoyl peroxide, form an emulsion under stirring at 500 rpm; polymerize at 90 °C for 4 h and then extract it with acetone for 12 h. Dry at 105°C for 4 hours to obtain a porous adsorption material. The porous adsorbent material for heavy metal Pb 2+ The adsorption capacity for the cationic dye methylene blue (MB) was 90.63 mg / g, and the adsorption capacity for the anionic dye acid fuchsin was 325.49 mg / g.

Example Embodiment

[0034] Example 3

[0035] Crumble oil shale semi-coke through a 400-mesh sieve; take 3 g of oil shale semi-coke powder, oAfter calcination at C for 2 h, add it to 25 mL of water, stir and disperse evenly at 500 rpm; then add 10 g of 3-(dimethylamino) ethyl acrylate, 22 g of acrylic acid, 3 g of azobisisobutyronitrile and 4 g of trimethylol Propane trimethacrylate, stirred at 500rpm and added 33 mL of n-hexane to form an emulsion, polymerized at 80°C for 8h and extracted with acetone Soxhlet for 24h, 105 o C and dried for 4 hours to obtain a porous adsorption material. The porous adsorbent material for heavy metal Pb 2+ The adsorption capacity for the cationic dye methylene blue (MB) was 210.59 mg / g, and the adsorption capacity for the anionic dye acid fuchsin was 335.71 mg / g, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap