Suspended bed hydrogenation multicomponent composite iron-based catalyst and preparation method thereof

An iron-based catalyst and multi-component composite technology, which is applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, preparation of liquid hydrocarbon mixtures, etc., can solve the problem of reduced iron usage, limited catalyst activity, Catalytic activity limitation and other problems, to achieve the effect of good dispersion, flexible composition of active components, and excellent catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

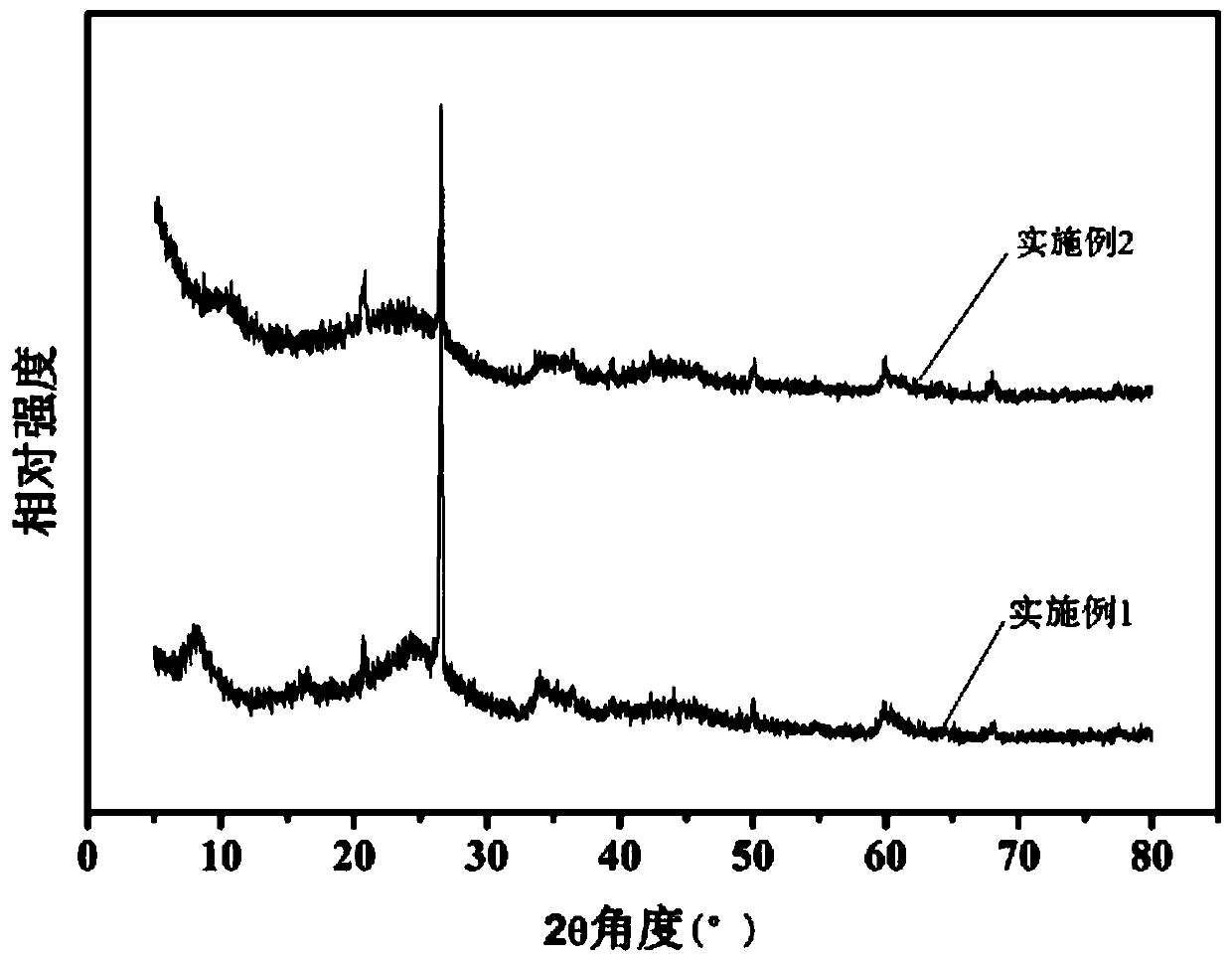

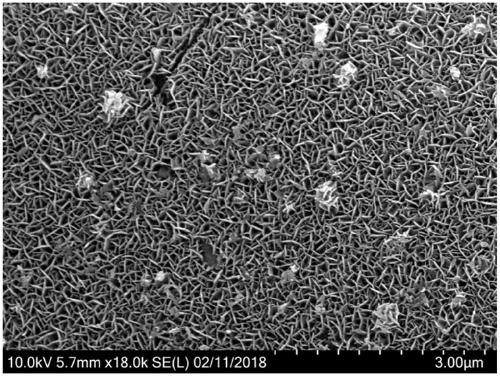

Embodiment 1

[0021] In terms of carrier, according to the loading of metal elements in Mg-Ni-Fe hydrotalcite as 5%, element molar ratio Mg:Ni:Fe=1:1:2, 0.23g MgSO 4 , 0.49g NiSO 4 ·6H 2 O, 1.03g FeSO 4 ·7H 2 O was dissolved in 75mL of deionized water, and then 6g of activated carbon with a particle size distribution of 400μm~2mm was added to the resulting solution, and the flow rate was 0.25m 3 At the same time, gradually add 0.25mol / L potassium hydroxide aqueous solution and 0.25mol / L sodium carbonate aqueous solution, control the pH of the reaction solution=6.5, stir and react at 60°C for 2 hours, filter with suction and keep at a constant temperature of 100°C Dry in a drying oven to obtain an activated carbon-supported Mg-Ni-Fe hydrotalcite catalyst.

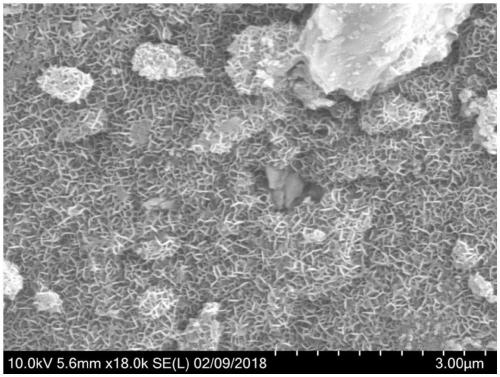

Embodiment 2

[0023] Based on the support, according to the loading of metal elements in the Co-Zn-Fe-Al hydrotalcite as 3%, the element molar ratio Co:Zn:Fe:Al=1:0.5:0.5:0.5, 0.149g Co(NO 3 ) 2 ·6H 2 O, 0.076g Zn(NO 3 ) 2 ·6H 2 O, 0.096g Al(NO 3 ) 3 9H 2 O, 0.033g FeCl 2 Dissolve in 75mL of deionized water, then add 2.8g of blue carbon with a particle size distribution of 50-500μm to the resulting solution, and pass it in at a flow rate of 0.5m 3 Oxygen per hour, at the same time gradually add 0.25mol / L sodium hydroxide aqueous solution, control the pH of the reaction solution = 8.0, stir and react at 30°C for 2 hours, filter with suction and dry in a constant temperature drying oven at 100°C to obtain blue carbon loaded Co-Zn-Fe-Al hydrotalcite catalyst.

Embodiment 3

[0025]In terms of carrier, according to the loading of metal elements in Co-Fe-Mo hydrotalcite as 5%, element molar ratio Co:Fe:Mo=1:1:1, 0.63kg FeSO 4 ·7H 2 O, 0.63kg CoSO 4 ·7H 2 O, 0.61kg MoCl 5 Dissolve it in 35L deionized water, then transfer the resulting solution into a 50L reactor, add 9.4kg of coal powder with a particle size distribution of 5-150μm into the reactor, and feed it with a flow rate of 2m 3 / h of air, while gradually adding 1 mol / L ammonia solution, controlling the pH of the reaction solution to 8.5, stirring and reacting at 35°C for 3 hours, centrifugal dehydration and drying in a constant temperature drying oven at 130°C to obtain Co- Fe-Mo hydrotalcite catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com