A mold core production process for forming high-precision spiral plastic products

A high-precision, mold core technology, applied in the field of plastic molds, can solve the problems of difficult realization of manufacturing technology, processing precision control and detection difficulties, so as to improve the convenience and accuracy of detection, meet the requirements of concentricity and verticality, and improve The effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions in the embodiments of the present invention will be apparent from the embodiments of the present invention, which will be described below. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

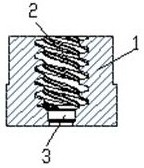

[0032] See Figure 1 ~ 12 , Embodiments of the present invention comprises:

[0033] A method for forming high-precision plastic spiral core manufacturing process, comprising the steps of:

[0034] Electrically core blank casting production, according to the coil 4 plastic (e.g. image 3 5 mandrel configuration shown) by five-axis CNC machining precision electroforming mold with a core (e.g. Figure 4 Shown), the plastic spiral plastic worm 4, the helical aperture comprises a helical spline on the inner wall of the aperture and the concave set requirements mandrel 5 tooth machining precision controlled within 0.002mm, use 5 electroforming mandrel productio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com