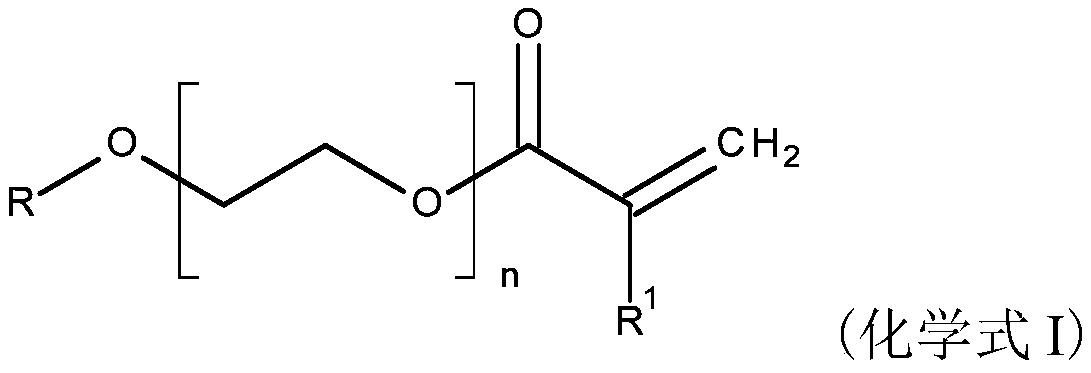

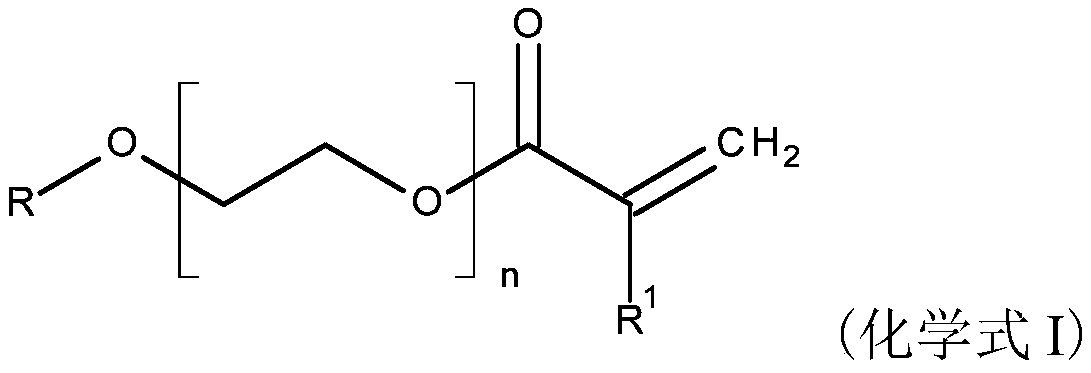

Vulcanizable composition containing hxnbr latex and polyfunctional epoxide

A technology of epoxide and composition, applied in the direction of rubber derivative coatings, clothing, applications, etc., can solve the problems of unsatisfactory end use, toxicity, insufficient thermal stability, etc. of cross-linkable dip-molded latex composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

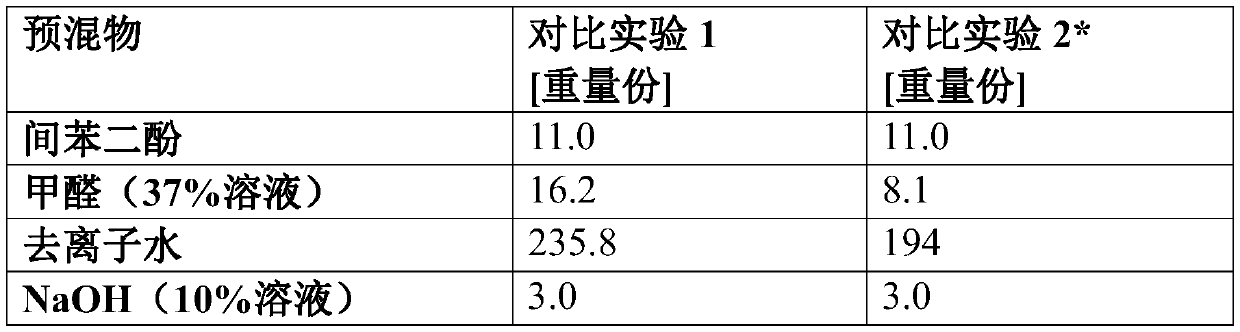

[0172] materials used

[0173] Latex (a)

[0174] XT-Latex Hydrogenated carboxylated secondary NBR latex; pH = 8.7; 40% by weight solids; 33% by weight acrylonitrile; 5% by weight methacrylic acid; commercially available from Arlanxeo Corporation

[0175] Crosslinking agent (b)

[0176] Multifunctional epoxy EUDERM Fix GA-I (bisphenol A-epichlorohydrin epoxy resin with average molecular weight <700); commercially available from LANXESS

[0177] Resorcinol Available from VWR Chemicals, 99.1%

[0178] Formaldehyde available from VWR Chemicals, 36%

[0179] Sulfur 50% colloidal sulfur dispersion, commercially available from agrostulln GmbH

[0180] Auxiliary

[0181] ZDBC Cure Accelerator; Zinc Dibutyl Dithiocarbamate

[0182] Bulk; available from Aquaspersions, 50% off

[0183] ZnO Zinc oxide; available from Aquaspersions, 50%

[0184] coagulation solution

[0185] Ca(NO 3 ) 2 *4H 2 O Calcium nitrate tetrahydrate; available from VWR

[0186] Triton X-100 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com