Multi-layer acidizing water injection string

A pipe string and formation technology, applied in the direction of drill pipe, casing, wellbore/well components, etc., can solve the problems of multiple construction procedures, increased operating costs, and increased processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

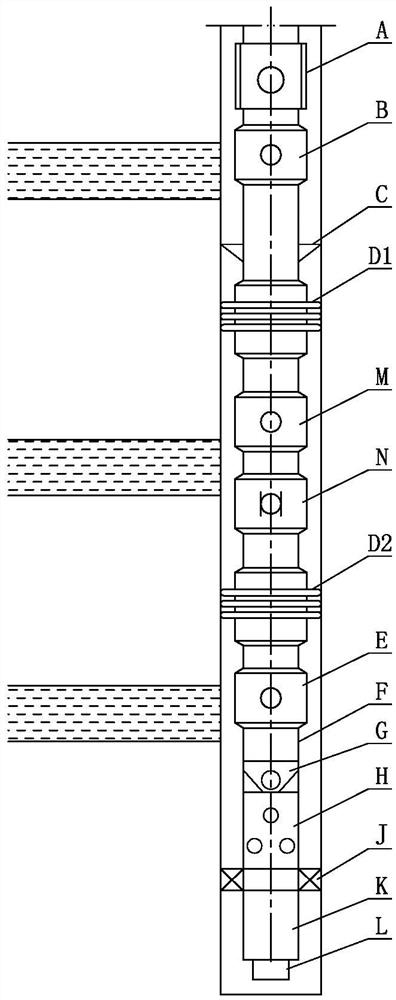

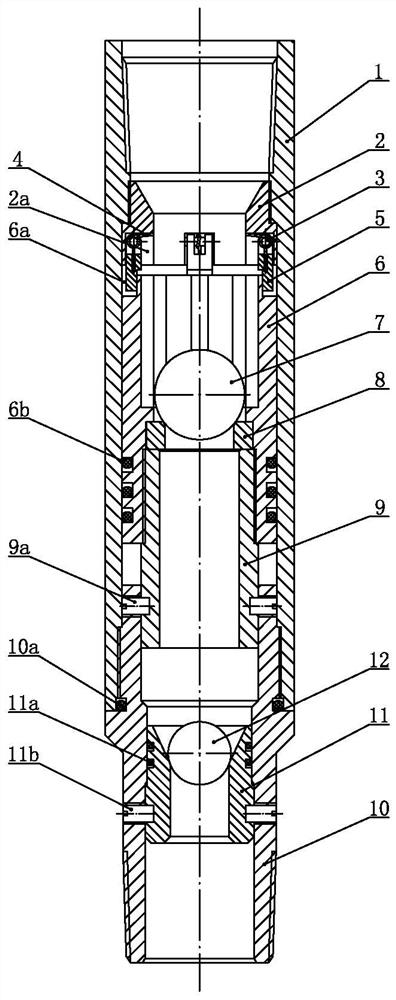

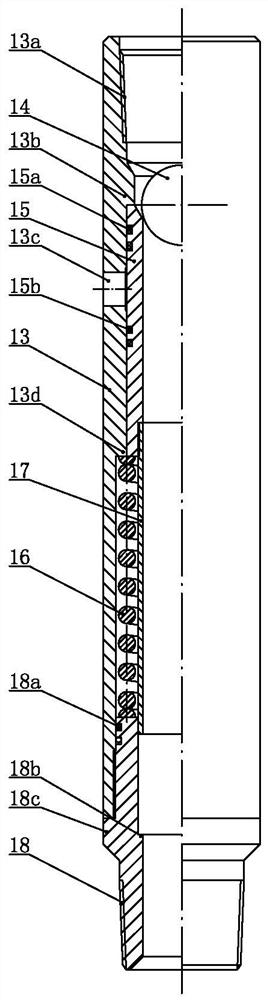

[0026] Such as figure 1 As shown, the multi-layer acidizing water injection string of the present invention includes an upper eccentric water distributor B corresponding to the upper water injection layer, a middle eccentric water distributor M corresponding to the middle water injection layer, and a lower eccentric water distributor corresponding to the lower water injection layer E. A centralizer C and a packer D1 are installed between the upper eccentric water distributor B and the middle eccentric water distributor M, and an intelligent acid injection valve N and a packer are installed between the middle eccentric water distributor M and the lower eccentric water distributor E Device 2 D2, an on-off valve A is installed above the upper eccentric water distributor B, an intermediate oil pipe F is installed under the lower eccentric water distributor E, and an acidizing check valve G is screwed under the intermediate oil pipe F, and the acidizing check valve G is The lower e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com