Method for synthesizing red mercury sulfide by using mechanical ball milling method at low temperature

A red mercury sulfide, mechanical ball milling technology, applied in chemical instruments and methods, inorganic chemistry, mercury compounds, etc., can solve the problems of complex production process, environmental pollution, etc., and achieve simple process, low energy consumption, and easy industrial production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

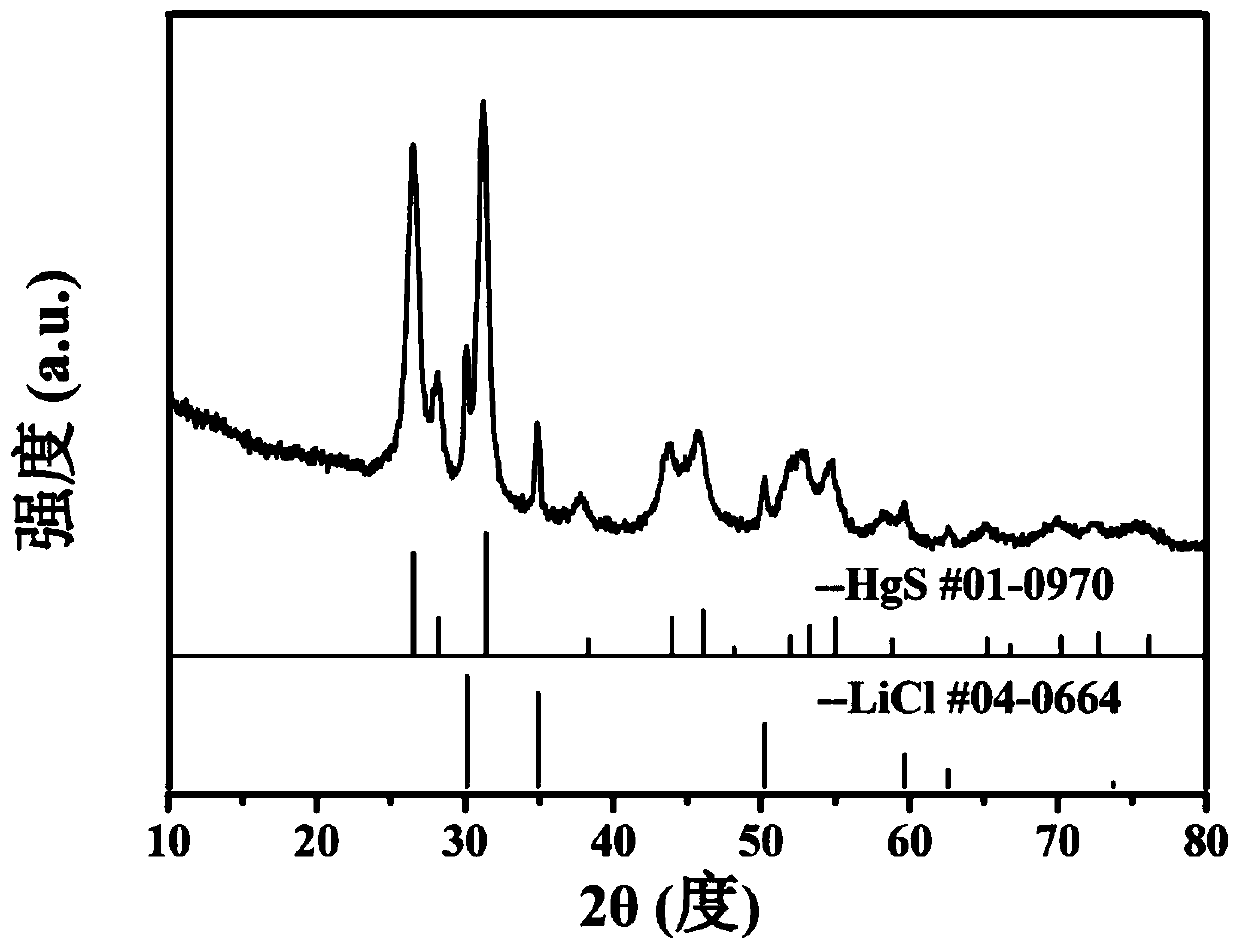

[0019] Anhydrous mercuric chloride and lithium sulfide were mixed under vacuum at a molar ratio of 1:1, the mixture was placed in a ball mill jar, and ball milled at a ball-to-material ratio of 30:1 at a speed of 500 r / min for 24 hours. After ball milling, take out the solid product, filter and wash it with deionized water, and dry it in an oven at 80°C to obtain mercury sulfide. The XRD pattern is as follows: figure 1 shown.

Embodiment 2

[0021] Under a nitrogen protective atmosphere, anhydrous mercuric chloride and lithium sulfide were mixed at a molar ratio of 1:2, the mixture was placed in a ball mill jar, and ball milled at a ball-to-material ratio of 100:1 at a speed of 300 r / min for 100 h. After ball milling, take out the solid product, filter and wash it with deionized water, and dry it in an oven at 70°C to obtain mercury sulfide.

Embodiment 3

[0023] Under an argon protective atmosphere, anhydrous mercury chloride and lithium sulfide were mixed at a molar ratio of 1:3, the mixture was placed in a ball mill jar, and ball milled at a ball-to-material ratio of 70:1 at a speed of 400 r / min for 50 h. After ball milling, take out the solid product, filter and wash it with deionized water, and dry it in an oven at 80°C to obtain mercury sulfide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com