Medium printing slurry and preparation method thereof

A medium printing and paste technology, which is applied in the field of preparation of ultra-fine-grained medium printing paste, can solve the problems of easy precipitation and uneven powder dispersion, and achieve the effects of not easy precipitation, convenient and simple viscosity adjustment process and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

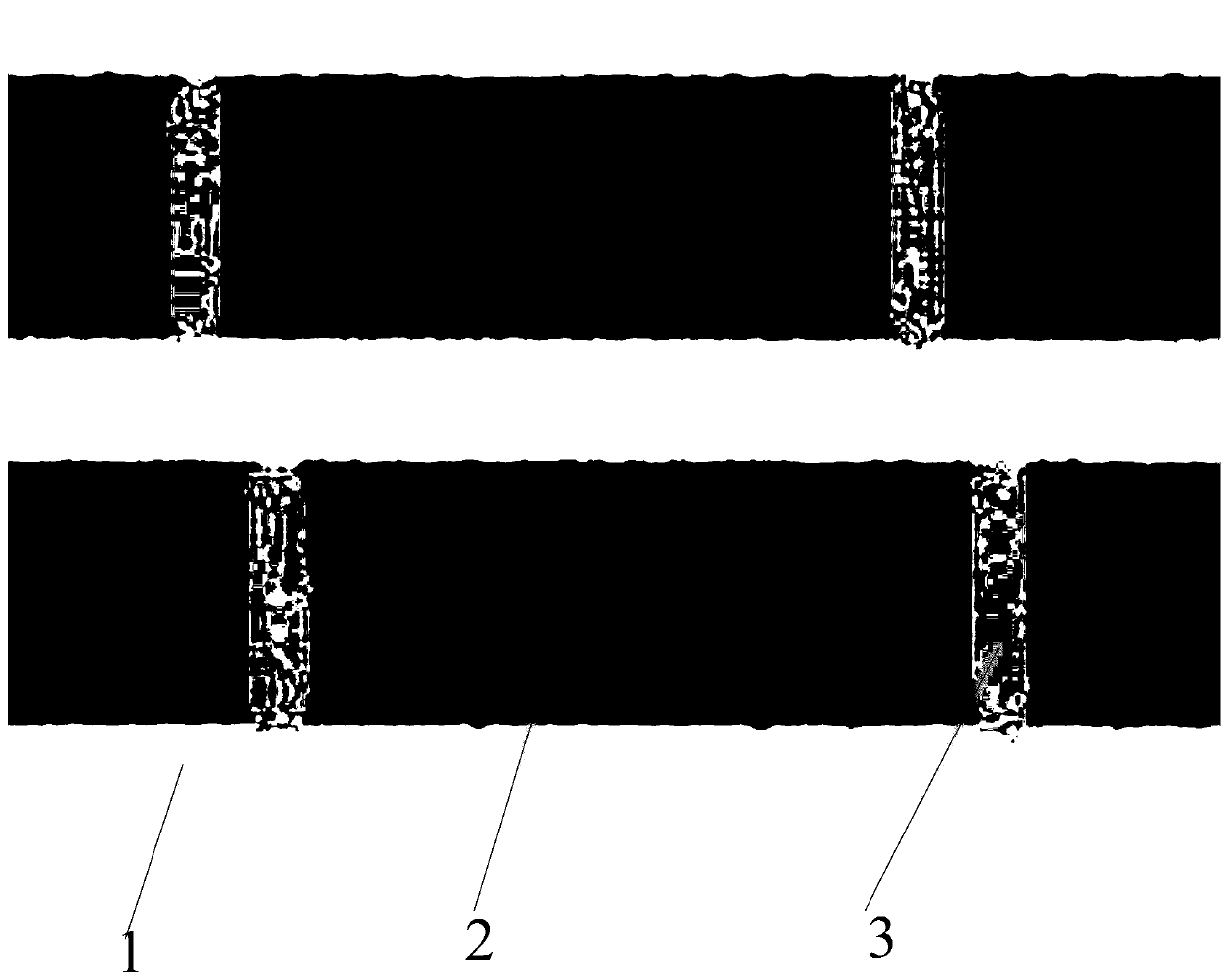

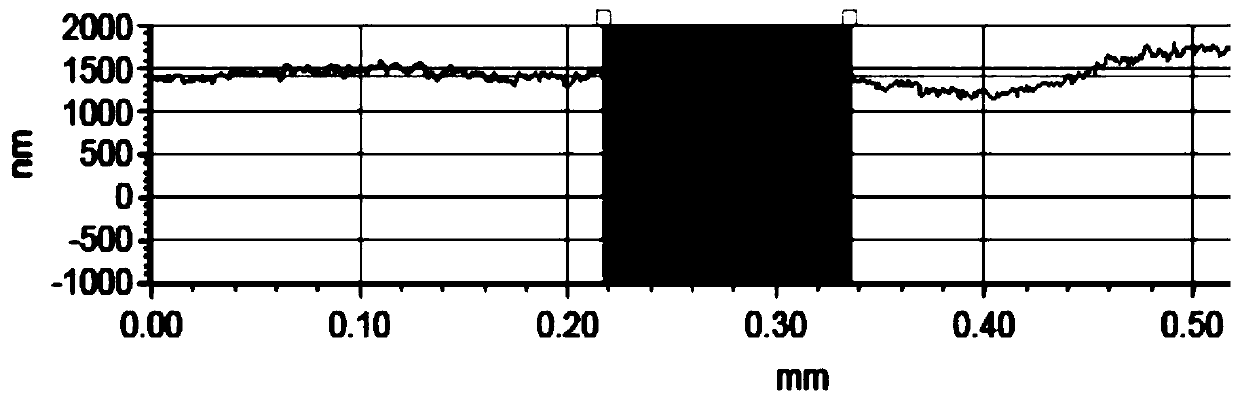

Image

Examples

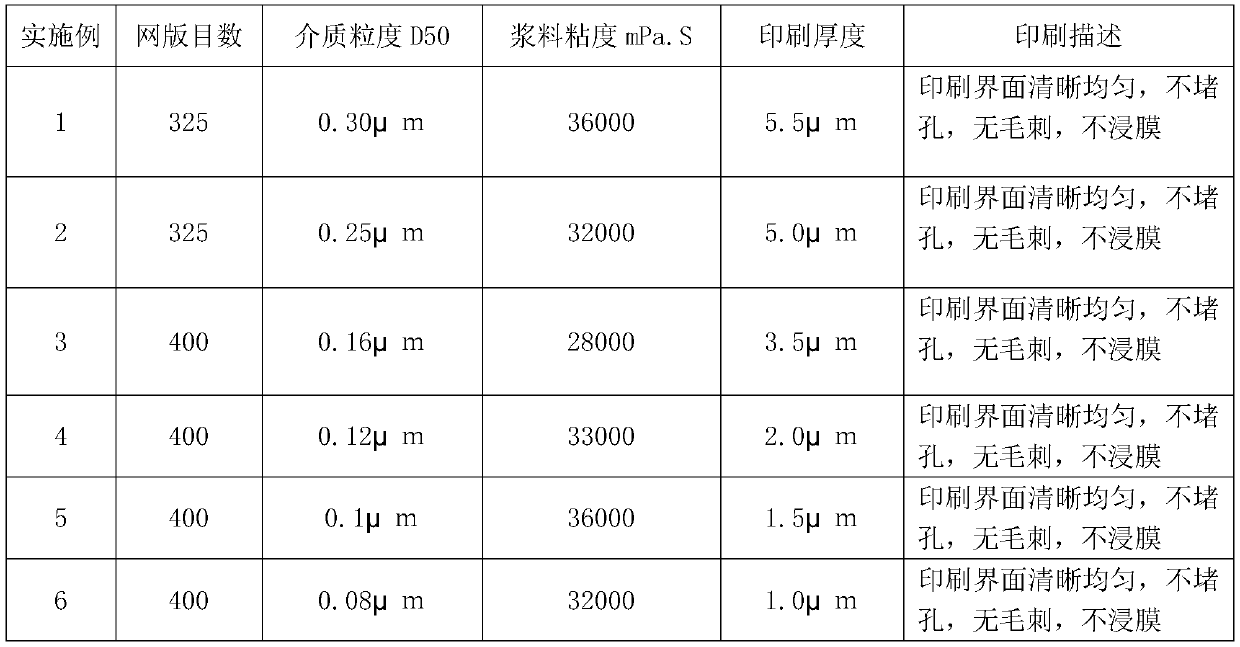

Embodiment 1

[0031] Prepare a 10L nylon ball mill tank, add 5 kg Φ3 zirconium balls, 5 kg Φ10 zirconium balls;

[0032] Step 1: Add 4 kg of ultra-fine-grain medium powder Ba with a median particle size D50 of 0.30 μm to the nylon ball mill tank 2 Ti 9 o 20 , 0.1 kg of dispersant polyethylene glycol octyl phenyl ether, 0.6 kg of toluene, 0.6 kg of ethanol, ball milling speed 40 rpm, ball milling for 4 hours;

[0033] Step 2: Add 0.15 kg of ethyl cellulose, 0.04 kg of DBP, 0.2 kg of turpentine, 0.7 kg of terpineol, mill at a speed of 40 rpm, and mill for 16 hours;

[0034] Step 3: The material is filtered with a 325-mesh filter, and the discharged slurry is impacted with 20KHz ultrasonic waves for 30 minutes at 25°C, stirred for 1 hour under the negative pressure of the draft, and the wind speed is 5 m / s, so that the toluene and ethanol are completely volatilized , adjust the viscosity to 36000mPa·S printing requirements, to obtain ultra-fine grain medium printing paste.

[0035] The obt...

Embodiment 2

[0037] Prepare a 10L ceramic ball mill jar, add 5 kg Φ3 zirconium balls, 5 kg Φ10 zirconium balls;

[0038] Step 1: Add 4 kg of ultra-fine-grain medium powder BaTi with a median particle size D50 of 0.25 μm to the nylon ball mill tank 4 o 9 , 0.12 kilograms of dispersant polyethylene glycol octyl phenyl ether, 0.5 kilograms of toluene, 0.5 kilograms of ethanol, 0.2 kilograms of isopropanol, ball milling speed 40 rpm, ball milling for 5 hours;

[0039] Step 2: Add 0.2 kg of ethyl cellulose, 0.05 kg of DBP, 0.1 kg of turpentine, 0.65 kg of diethylene glycol ether, ball mill at 40 rpm, and ball mill for 17 hours;

[0040] Step 3: The material is filtered with a 325-mesh filter, and the discharged slurry is impacted with 20KHz ultrasonic wave at 25°C for 20 minutes, stirred for 2 hours under the negative pressure of the draft, and the wind speed is 1 m / s, so that toluene, ethanol, iso The propanol is completely volatilized, and the viscosity is adjusted to 32000mPa·S printing re...

Embodiment 3

[0043] Prepare a planetary mill, 4 2L nylon ball mill tanks, 5 kg Φ1 zirconium balls, 5 kg Φ3 zirconium balls;

[0044] Step 1: Add 4 kg of ultra-fine-grain medium powder BaTiO with a median particle size D50 of 0.16 μm to the nylon ball mill tank 3 , 0.16 kilograms of dispersant polyethylene glycol octyl phenyl ether, 0.6 kilograms of toluene, 0.6 kilograms of propyl acetate, ball milling speed 300 rpm, ball milling 1 hour;

[0045] Step 2: Add 0.28 kg of ethyl cellulose, 0.1 kg of DOP, 0.2 kg of turpentine, 0.7 kg of terpineol, mill at a speed of 260 rpm, and mill for 2 hours;

[0046] Step 3: The material is filtered with a 400-mesh filter, and the discharged slurry is impacted with 20KHz ultrasonic waves for 30 minutes at 25°C, stirred for 2 hours under negative pressure, and the wind speed is 1 m / s to make toluene and propyl acetate Completely volatilize, adjust the viscosity to 28000mPa·S printing requirements, and get ultra-fine grain medium printing paste.

[0047] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com