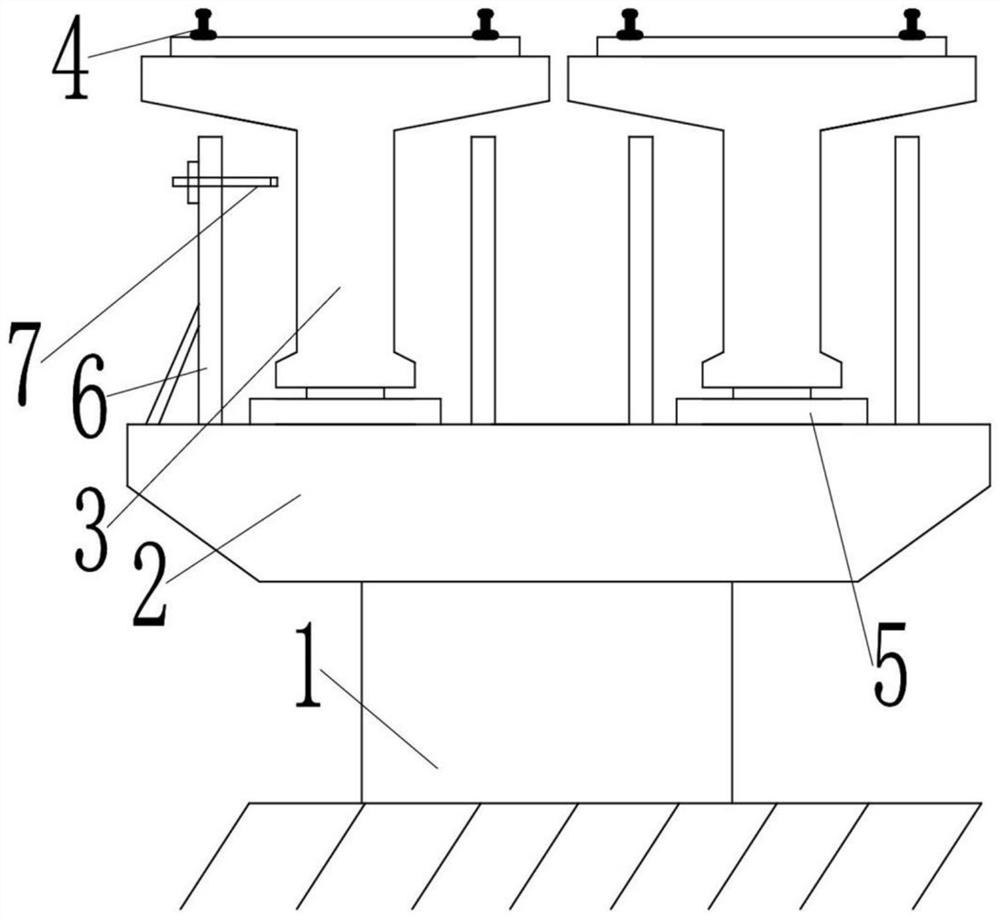

Rail bridge beam end jacking and repairing device

A technology for overhauling equipment and railways, which is applied in bridge maintenance, bridges, bridge construction, etc., and can solve problems such as unfavorable force on the track, large area of concrete crushing, and longitudinal movement of the beam body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In the first embodiment, the displacement detection device 8 includes a combined support channel steel structure 6 set on the cover beam 2, and a slideway type displacement sensor 7 set on the combined support channel steel structure 6. The disadvantage is that real-time accurate detection cannot be realized, and the cost High, manual coordination is required, the structure is complex, and it is not suitable for mass use.

Embodiment 2

[0026] In the second embodiment, the displacement detection device 8 includes a cylinder tailstock arranged at the head end of a T-beam 3 and positioned at the upper and lower sides of the vertical beam of the T-beam 3, a displacement piston member 17 arranged in the cylinder tailstock for longitudinal movement, and a The return spring 18 on the displacement piston 17, the outer top fitting 19 that is arranged at the tail end of a T beam 3 and is used to correspond to the head of the displacement piston 17, and the triangle between the back of the outer top fitting 19 and the T beam 3 Rib 20;

[0027] The center-to-center distance of the cylinder tailstock is greater than or equal to the width of the T-beam 3 crossbeam.

[0028] Since the T-beam is solid, when the side moves or deflects or approaches, the edges of both ends approach first or at the same time. As long as the two ends are monitored, pre-judgment detection can be realized and the disadvantages of post-processing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com