Safe power-off system of tobacco primary processing equipment

A kind of equipment and silk-making technology, which is applied in the direction of tobacco, tobacco processing, program control in sequence/logic controller, etc. It can solve the problems that the equipment cannot be cooled according to the set time, the cooling time of the equipment is long, and the power of the operator is cut off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to enable those skilled in the art to better understand the solutions of the embodiments of the present invention, the embodiments of the present invention will be further described in detail below in conjunction with the drawings and implementations.

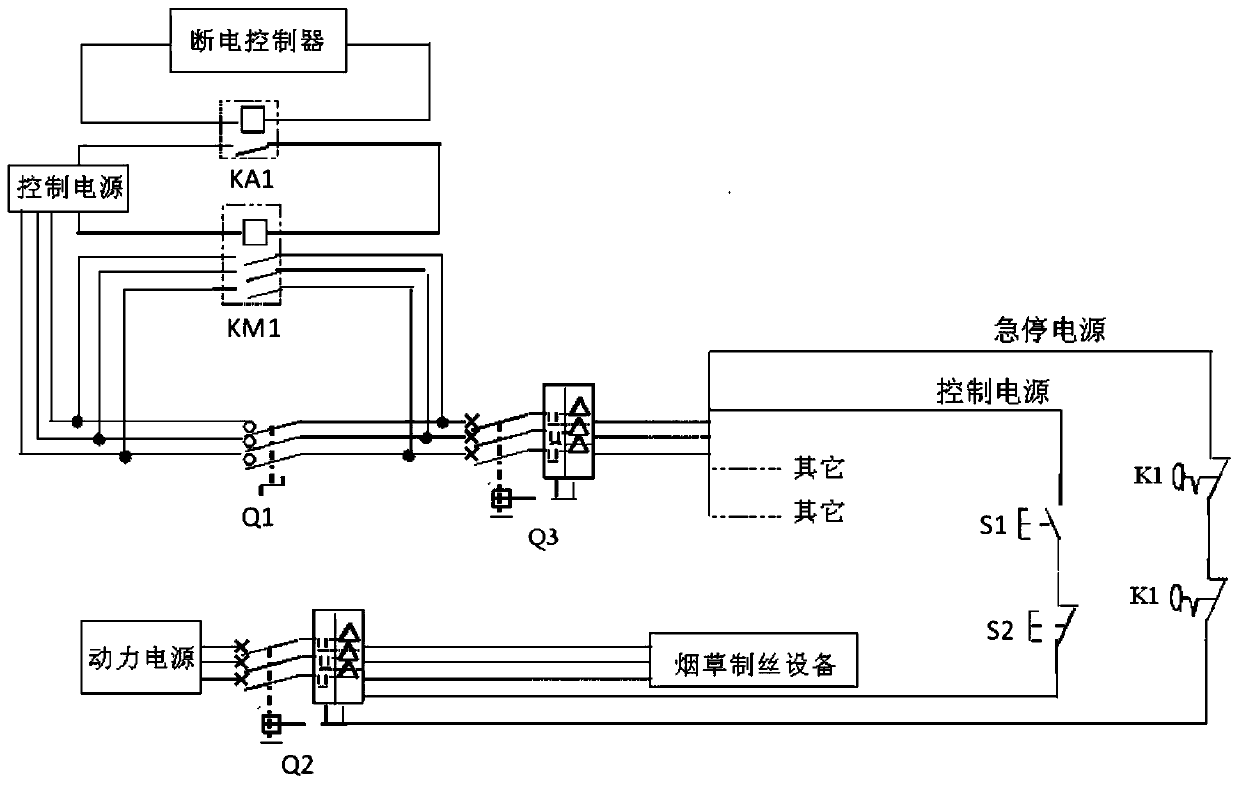

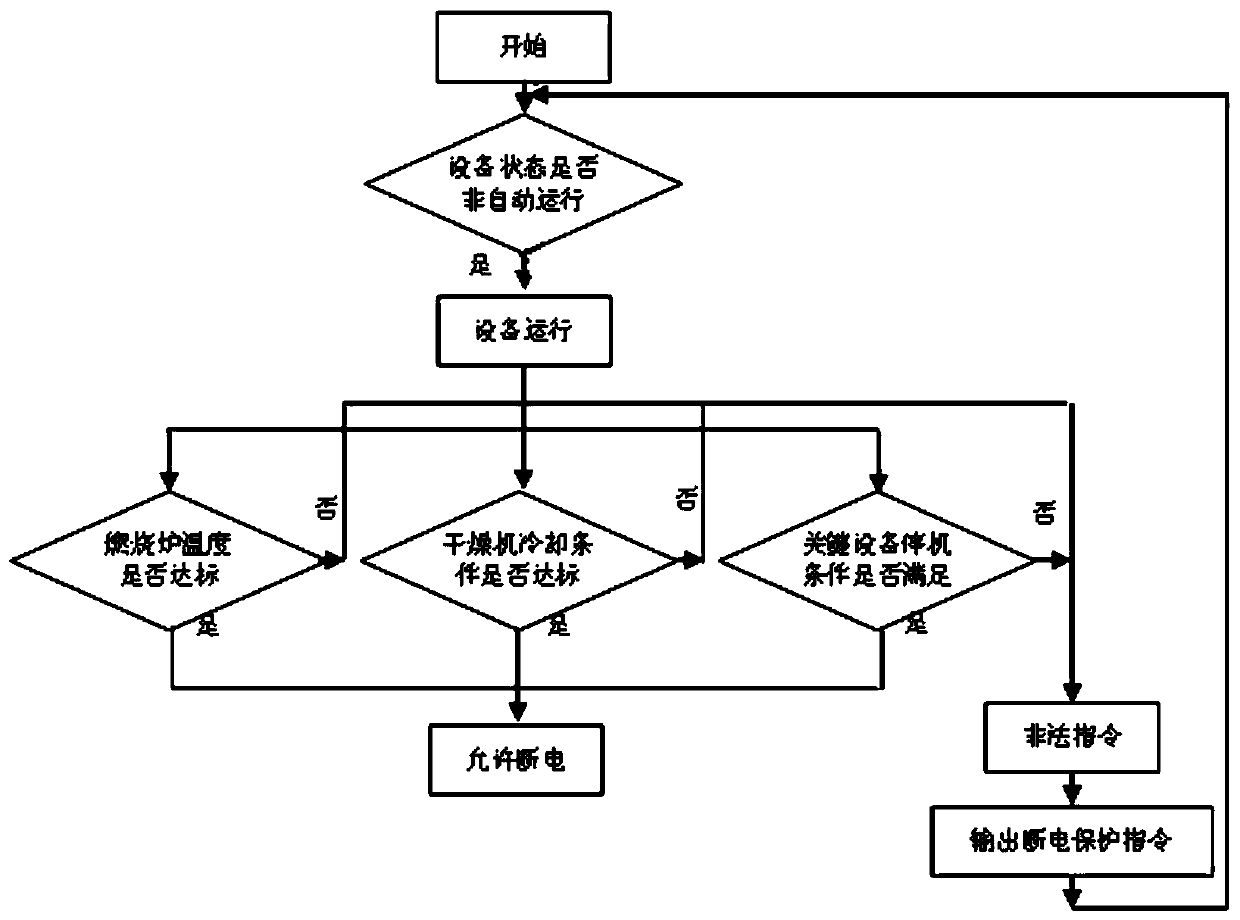

[0042] In the current tobacco shred production process, operators often cut off the power and leave work without waiting for the equipment to cool down, causing heat to accumulate in the equipment and cannot be quickly dissipated, which will have a negative impact on the equipment over time. The invention provides a safety power-off system for shredded tobacco equipment. By connecting a contactor in parallel with the control power switch, when both the contactor and the control power switch are disconnected, the power supply switch of the tobacco shredded equipment is disconnected. It solves the problem that the existing tobacco equipment takes a long time to cool down after the end of production, and it is easy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com