A humanoid soft finger with origami structure based on conductive thermoplastic starch polymer

A technology of thermoplastic starch and origami structure, which is applied in the field of humanoid soft fingers, can solve problems such as joint rigidity that cannot be bent, lower joints, and long response time, and achieve the effects of shortening response time, increasing contact area, and improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0039] Specific implementation mode one: combine figure 1 with figure 2 To illustrate this embodiment, a method for preparing a conductive thermoplastic starch polymer in this embodiment comprises the following steps:

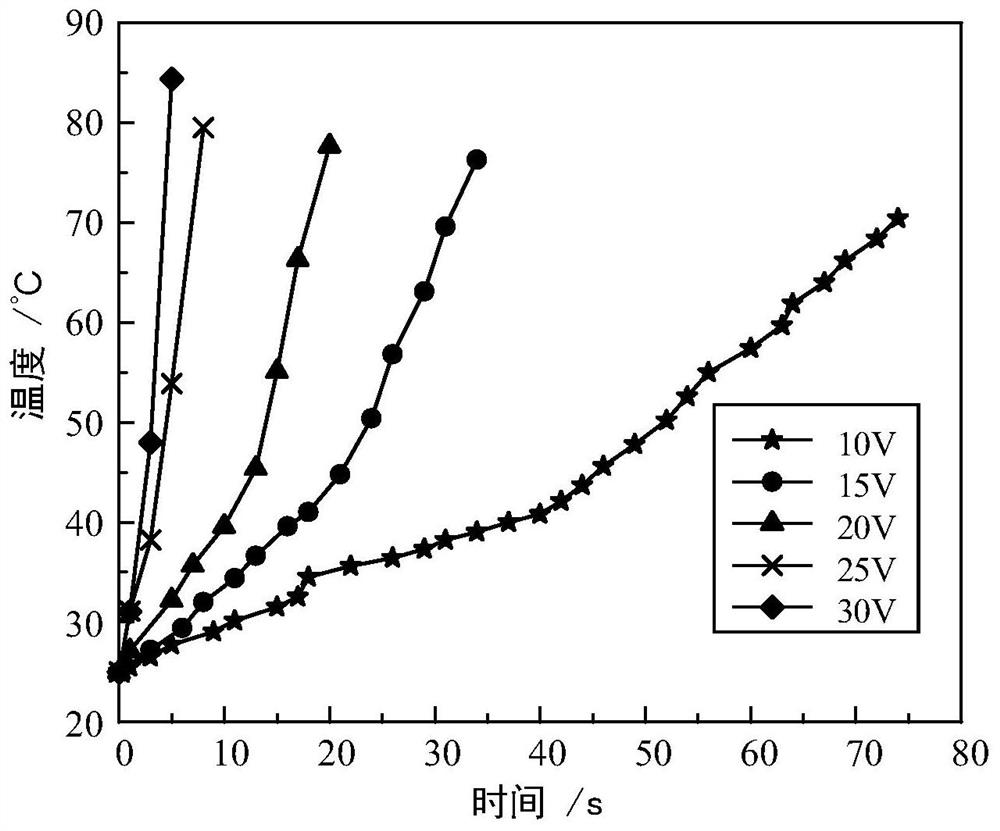

[0040]mixing thermoplastic starch polymer particles and multi-wall carbon nanotubes in a certain proportion, wherein the mass fraction of multi-wall carbon nanotubes is 5%-20%, and placing thermoplastic starch polymer particles and multi-wall carbon nanotubes in a vessel During the heating process, continuous centrifugal stirring is carried out, and the thermoplastic starch polymer changes from a glassy state to a viscous fluid state, and finally fully fuses with the multi-walled carbon nanotubes, and finally the conductive thermoplastic starch polymer is compacted.

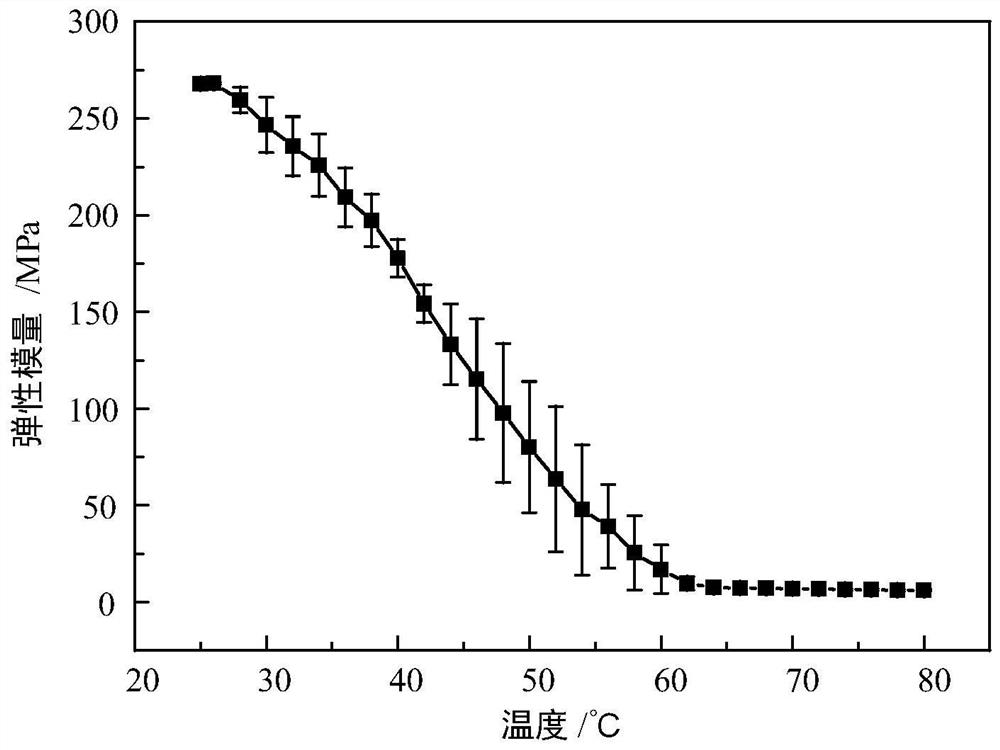

[0041] Such as figure 1 As shown, the glass transition temperature of the conductive thermoplastic starch polymer is about 60°C, and the elastic modulus can change from 268MPa at 25°C to 7.4MPa...

specific Embodiment approach 2

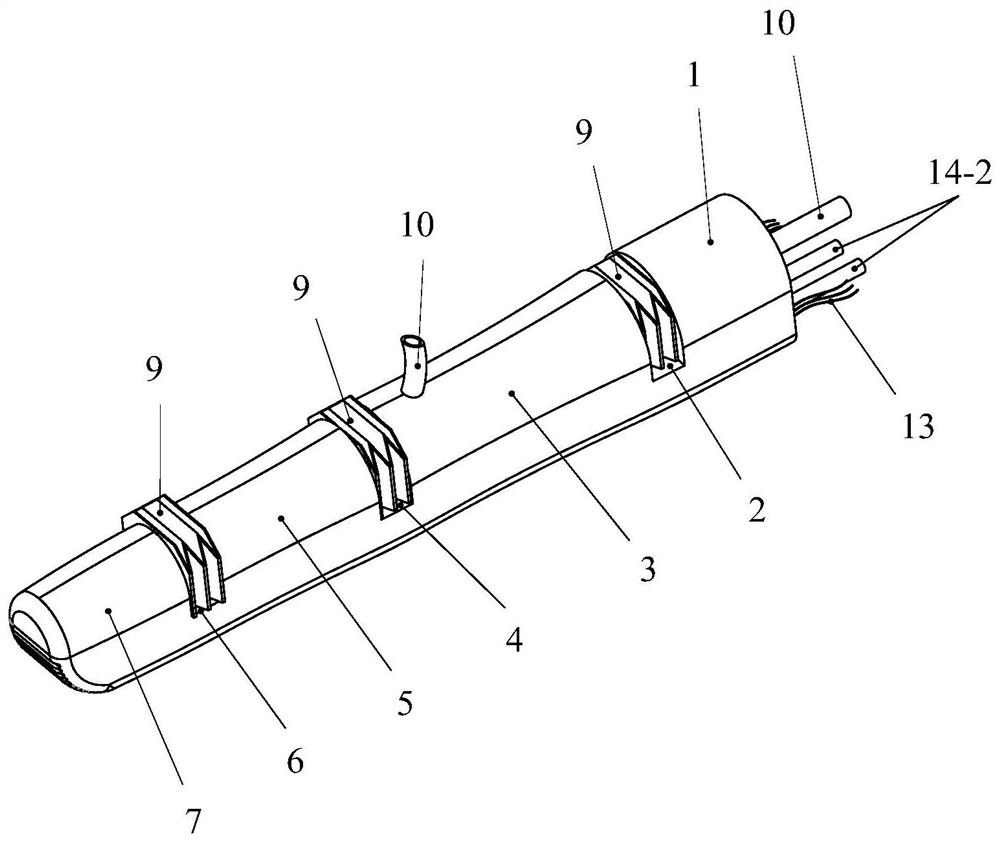

[0043] Specific implementation mode two: combination image 3 with Figure 4 To illustrate this embodiment, a humanoid soft finger with an origami structure based on conductive thermoplastic starch polymers in this embodiment includes finger roots 1, metacarpophalangeal joints 2, proximal phalanx 3, interphalangeal joint 4, and middle phalanx 5 , fingertip joint 6, distal phalanx 7, strain constrained layer 11, variable stiffness layer, cooling layer 14, contact layer 15 and Yoshimura pattern origami 9;

[0044] Root of finger 1, proximal phalanx 3, middle phalanx 5, and distal phalanx 7 are connected by metacarpophalangeal joint 2, interphalangeal joint 4, and fingertip joint 6 in sequence. Metacarpophalangeal joint 2, proximal phalanx 3. The interphalangeal joint 4, the middle phalanx 5, the fingertip joint 6 and the distal phalanx 7 are all provided with hollow cavities, and the hollow cavities of the metacarpophalangeal joint 2 and the proximal phalanx 3 communicate with ...

specific Embodiment approach 3

[0051] Specific implementation mode three: combination Figure 5-Figure 8 To illustrate this embodiment, a humanoid soft finger with an origami structure based on conductive thermoplastic starch polymers in this embodiment includes finger roots 1, metacarpophalangeal joints 2, proximal phalanx 3, interphalangeal joint 4, and middle phalanx 5 , fingertip joint 6, distal phalanx 7, strain constrained layer 11, variable stiffness layer, cooling layer 14, contact layer 15 and Yoshimura pattern origami 9;

[0052] Root of finger 1, proximal phalanx 3, middle phalanx 5, and distal phalanx 7 are connected by metacarpophalangeal joint 2, interphalangeal joint 4, and fingertip joint 6 in sequence. Metacarpophalangeal joint 2, proximal phalanx 3. The interphalangeal joint 4, the middle phalanx 5, the fingertip joint 6 and the distal phalanx 7 are all provided with hollow cavities, and the hollow cavities of the metacarpophalangeal joint 2 and the proximal phalanx 3 communicate with each...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com