Logistics sorting machine

A sorter and logistics technology, applied in sorting and other directions, can solve the problems of inconvenient disassembly and assembly of the logistics sorter, inconvenient disassembly and assembly during maintenance of the logistics sorter, etc., and achieves reliable power supply structure, compact structure, and easy use. Long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

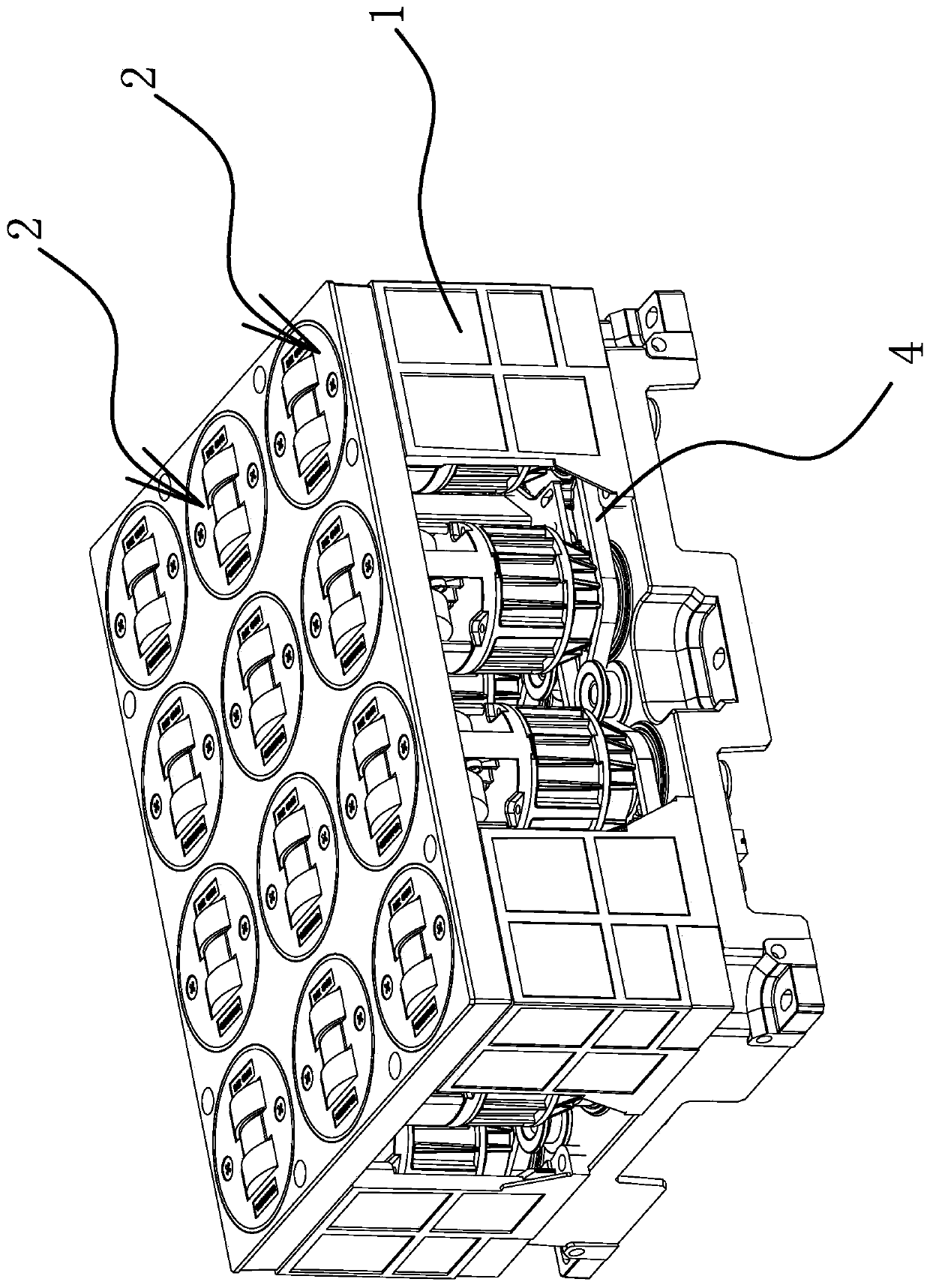

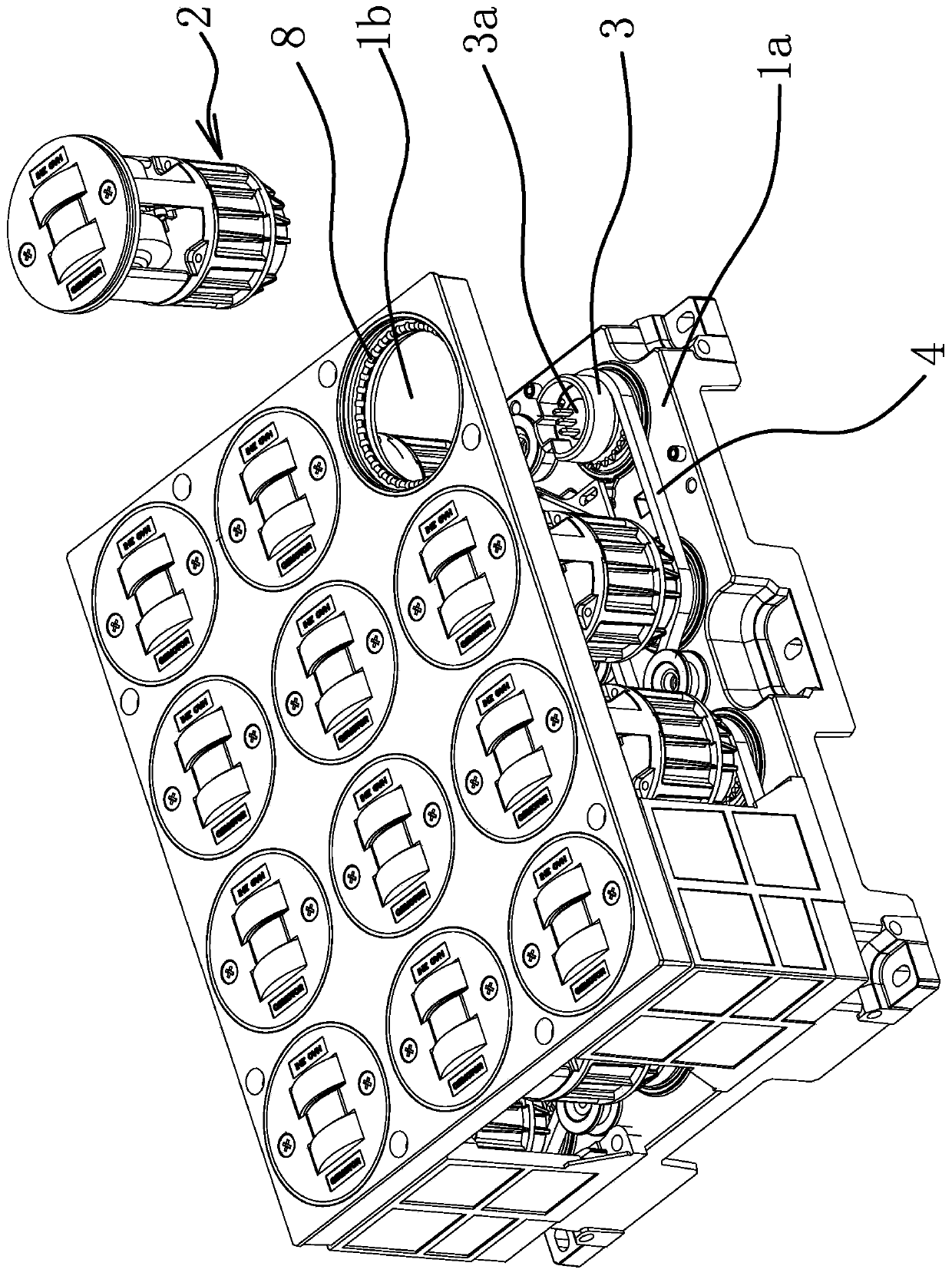

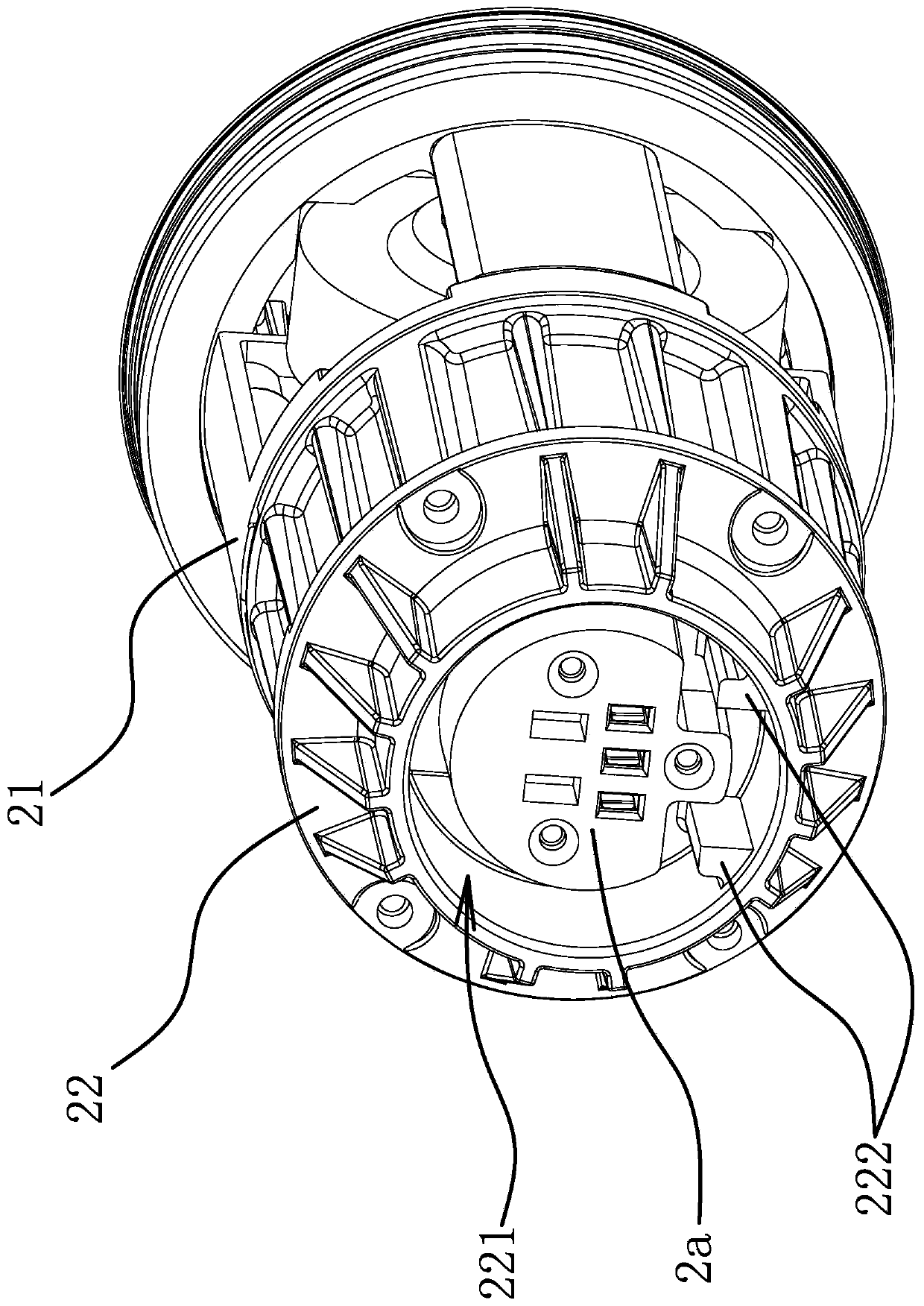

[0036] Specifically, as figure 1 with figure 2 As shown, the logistics sorting machine includes a base 1, a number of columnar roller motor modules 2 for material transportation, and a turntable 3 corresponding to the roller motor modules 2 one by one. The table of the base 1 is provided with a roller motor The installation through hole 1b where the module 2 is installed, several swivel bases 3 are rotatably connected in the base 1 and each swivel base 3 is connected and driven by the transmission part 4 and can rotate synchronously. The roller motor module 2 passes through the installation through hole 1b Inserted on the swivel seat 3, electrical communication can be realized while realizing circumferential positioning....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com