Segmental precast assembled pier and construction method thereof

A technology of prefabricated assembly and bridge piers, applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., to achieve the effect of increasing the amount of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

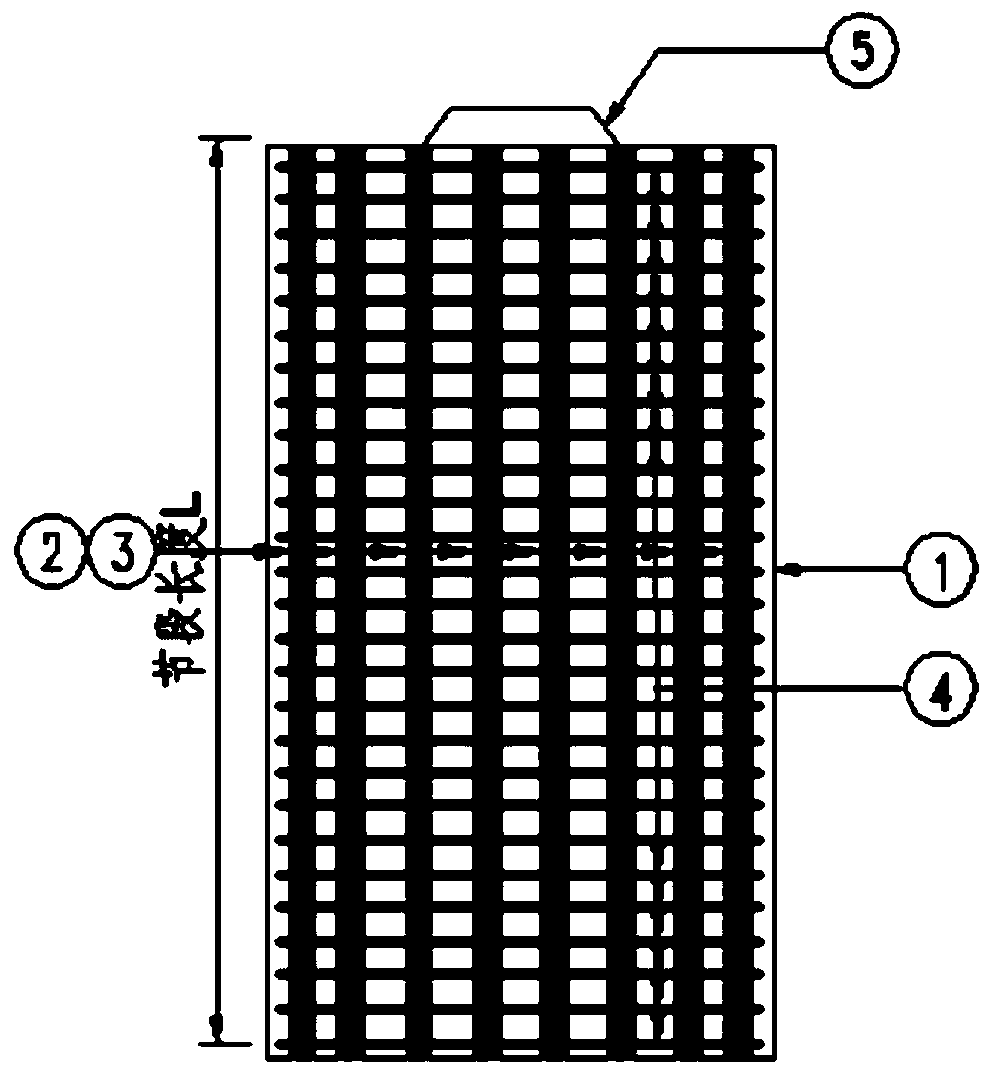

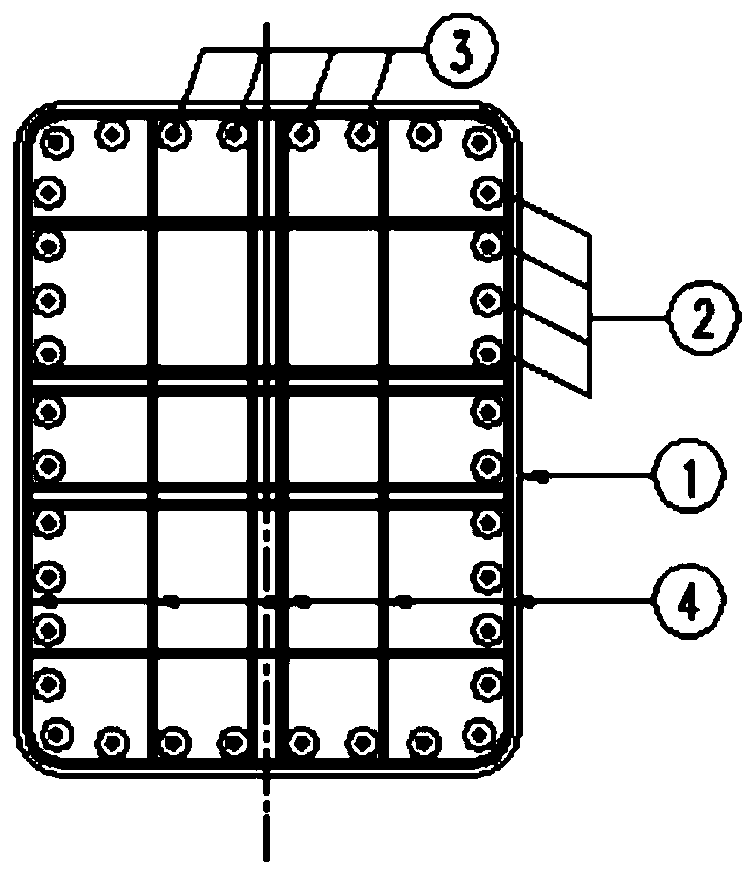

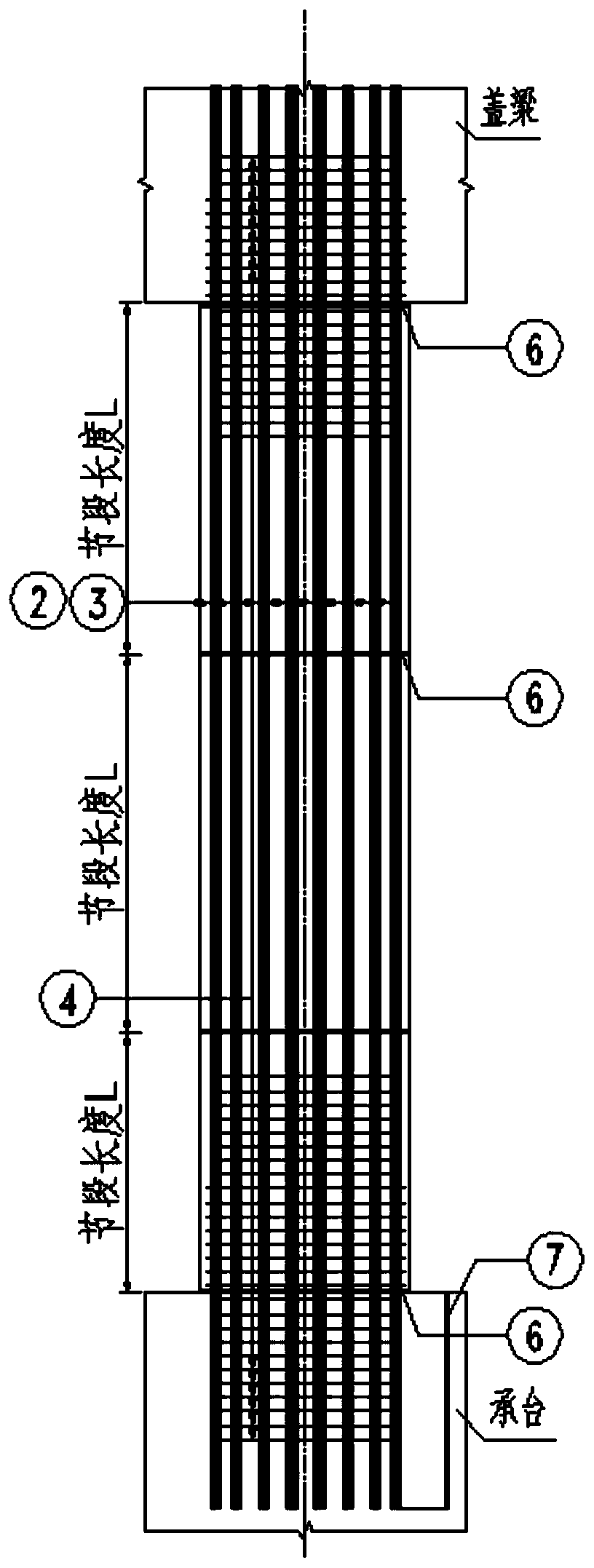

[0039] Such as Figure 1 to Figure 3 As shown, the segmental prefabricated assembled pier includes a pier main body, and the upper and lower ends of the pier main body are respectively provided with a cap beam and a cap.

[0040] Wherein, the main body of the bridge pier includes several sections 1, each of which is a prefabricated part, and several sections 1 are connected end to end from bottom to top to form the main body of the pier;

[0041] Each segment 1 is a strip structure extending in the vertical direction, and is provided with a number of reserved holes 2 around the side;

[0042] Each reserved channel 2 is a through hole penetrating from the top to the bottom of the corresponding segment 1, and each reserved channel 2 is provided with a stressed main rib 3;

[0043] On the side of each segment 1, on the outside of the corresponding reserved channels 2, there are surrounding stirrups 4 around the channel;

[0044] Each segment 1 is provided with a positioning she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com