Dry recycling method for waste power lithium battery

A dry recycling, lithium battery technology, applied in battery recycling, waste collector recycling, recycling technology, etc., can solve the problems of environmental pollution, energy consumption, low recycling rate, etc., to achieve the effect of easy operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

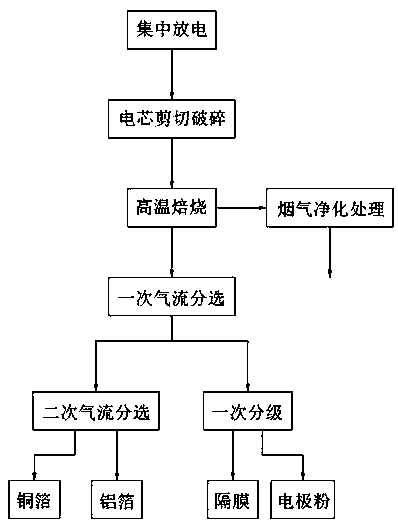

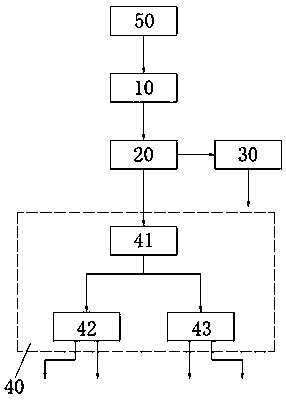

[0042] Combine below Figure 1 to Figure 2 , the present invention is further described:

[0043] Such as figure 1 As shown, a large number of waste power lithium batteries in the market cannot be properly treated, which will restrict the development of society. The current treatment technology has problems of low recovery efficiency, high treatment pressure, and serious environmental pollution. Aiming at this problem, the present invention provides a dry recovery method for waste power lithium batteries, which includes the following steps: S1, crushing the battery cells by shearing and crushing to obtain electrode scraps and diaphragms; S2, crushing the electrode scraps The material is subjected to high-temperature treatment, the binder is removed, and the electrode powder and the copper-aluminum mixture are obtained by grinding with a stirring mill; S3, the electrode powder, the copper-aluminum mixture and the diaphragm are subjected to airflow separation by a variable-diam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com