Case for moving welding machine

A welding machine and chassis technology, applied in the field of mobile welding machine chassis, can solve the problems of heavy workload and inconvenient use of operators, and achieve the effects of simplified operation steps, convenient use, and increased operating space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0019] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

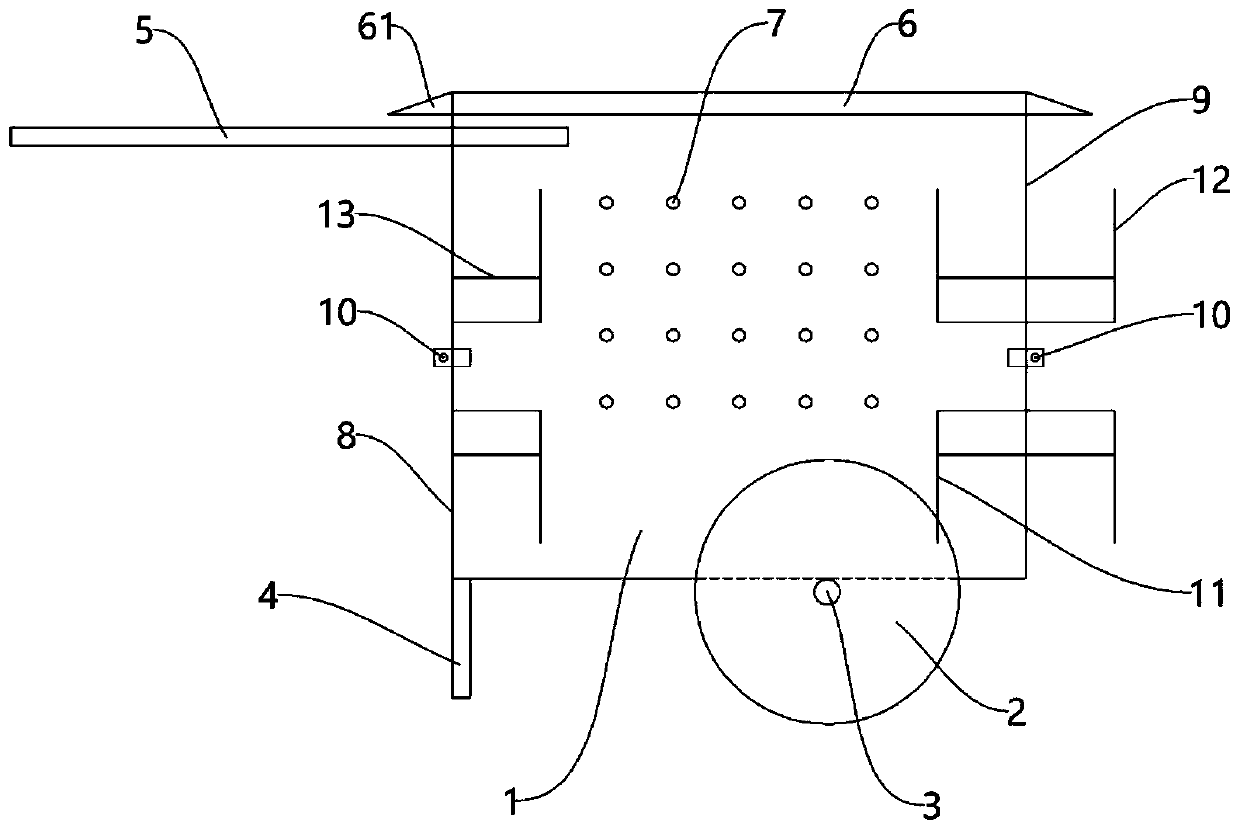

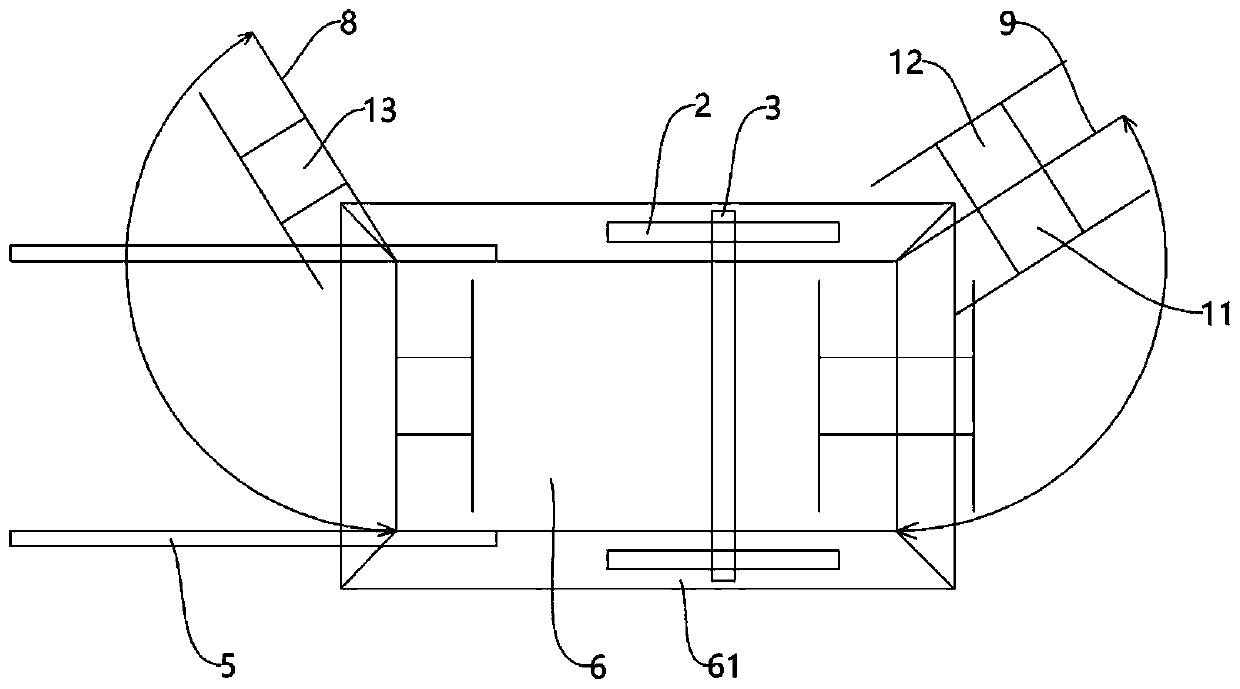

[0020] A preferred embodiment of a mobile welding machine cabinet of the present invention, such as Figure 1 to Figure 3 As shown, the case for the mobile welding machine includes a box body 1, the box body 1 has a cubic structure as a whole, and the inside of the box body 1 forms an accommodating chamber for accommodating the welding machine.

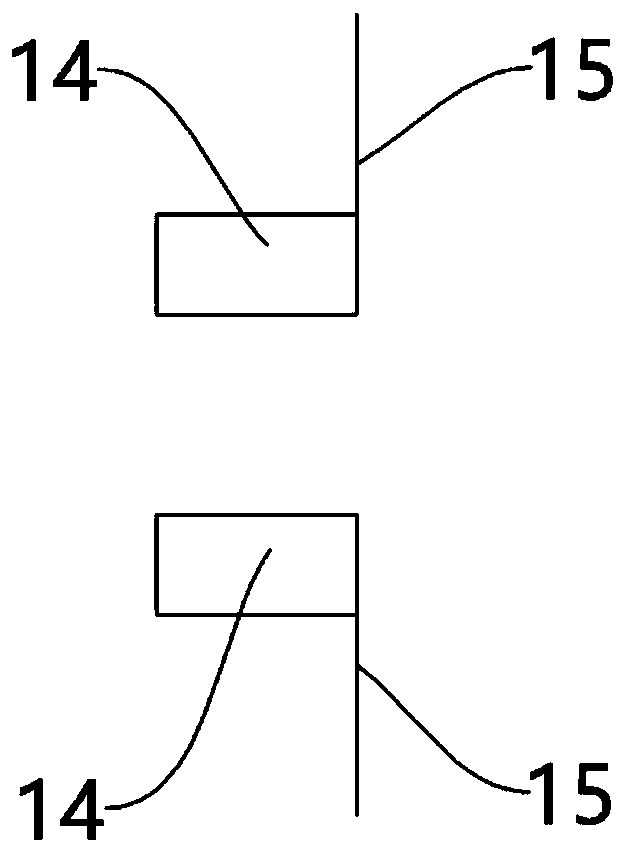

[0021] The bottom of the casing 1 is provided with wheels 2, and there are two wheels 2, which are connected by a wheel axle 3 between the two wheels 2. The box body 1 is also symmetrically arranged with two supporting feet 4 on the front side of the bottom, and the supporting feet 4 are used to cooperate with the wheels 2 to sup...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap