Method for preparing electrolyte membrane electrode body by utilizing interfacial polymerization reaction

An electrolyte membrane electrode, interfacial polymerization technology, used in battery electrodes, circuits, fuel cells, etc., can solve problems such as poor stability and electrical conductivity, and achieve the effects of improving dispersion performance, easy operation, and low threshold.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

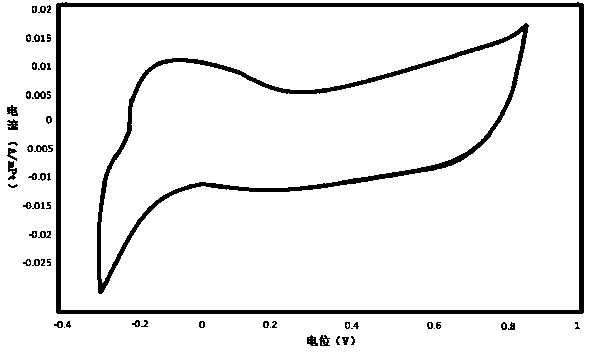

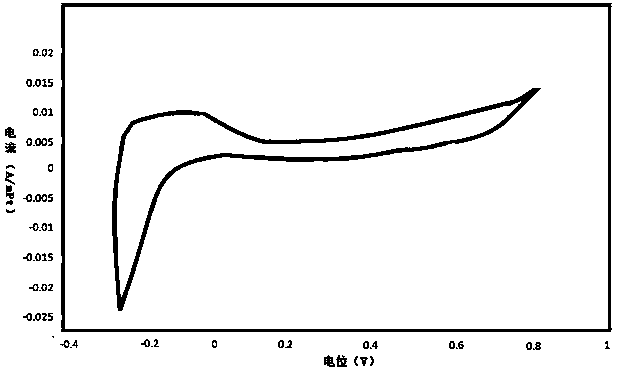

Image

Examples

Embodiment 1

[0044] (1). Mix 2g of Pt / C catalyst particles with a particle size of 5-10nm, 200g of water, 300g of Nafion solution with a mass concentration of 10%, and 200g of active monomers with sulfonic acid groups, 2 , 2 '-bissulfonic acid Acid benzidine was ultrasonically dispersed for 30 minutes at a power of 80W, and the pH regulator was adjusted to 8 to obtain an aqueous phase catalyst slurry;

[0045] (2). Dispersing 120g of the acid chloride monomer terephthaloyl chloride and 80g of carbon powder in 600g of organic solvent dimethylformamide to obtain an oil phase; the organic solvent is chloroform;

[0046] (3). The perfluorosulfonic acid-type proton exchange membrane Nafion 117 on both sides of the surface is pressed out non-penetrating micropores by needle punching with a roller. The needle spacing is 0.2mm, and then the ultrasonic atomization equipment with a working frequency of 1.7MHz is used. The aqueous catalyst slurry in step (1) is uniformly sprayed on both sides of the ...

Embodiment 2

[0050] (1). 4g of Pt / C catalyst particles with a particle size of 5-8nm, 250g of water, 400g of Nafion solution with a mass concentration of 15%, and 200g of active monomers with sulfonic acid groups 2 , 2 '-bissulfonic acid Acid benzidine was ultrasonically dispersed for 30 minutes at a power of 60W, and the pH regulator was adjusted to 8 to obtain an aqueous phase catalyst slurry;

[0051] (2). Dispersing 120g of the acid chloride monomer terephthaloyl chloride and 80g of carbon powder in 600g of organic solvent dimethylformamide to obtain an oil phase; the organic solvent is chloroform;

[0052] (3). The perfluorosulfonic acid-type proton exchange membrane Nafion 117 on both sides of the surface is pressed out non-penetrating micropores by needle punching with a roller. The needle spacing is 0.2mm, and then the ultrasonic atomization equipment with a working frequency of 1.7MHz is used. The aqueous catalyst slurry in step (1) is uniformly sprayed on both sides of the proton...

Embodiment 3

[0056] (1). Mix 6g of Pt / C catalyst particles with a particle size of 8-10nm, 200g of water, 500g of Nafion solution with a mass concentration of 10%, and 300g of active monomers with sulfonic acid groups, 2 , 2 '-bissulfonic acid Acid benzidine was ultrasonically dispersed for 40min at a power of 90W, and the pH regulator was adjusted to 8.5 to obtain an aqueous phase catalyst slurry;

[0057] (2). Disperse 200g of the acid chloride monomer terephthaloyl chloride and 100g of carbon powder in 600g of organic solvent dimethylformamide to obtain an oil phase; the organic solvent is chloroform;

[0058] (3). The perfluorosulfonic acid-type proton exchange membrane Nafion 117 on both sides of the surface is pressed out non-penetrating micropores by needle punching with a roller. The needle spacing is 0.2mm, and then the ultrasonic atomization equipment with a working frequency of 1.7MHz is used. The aqueous catalyst slurry in step (1) is uniformly sprayed on both sides of the prot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com