Oil stain separation sedimentation tank

An oil pollution separation and sedimentation tank technology, which is applied in the fields of flocculation/sedimentation water/sewage treatment, water/sewage treatment, water/sewage treatment equipment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

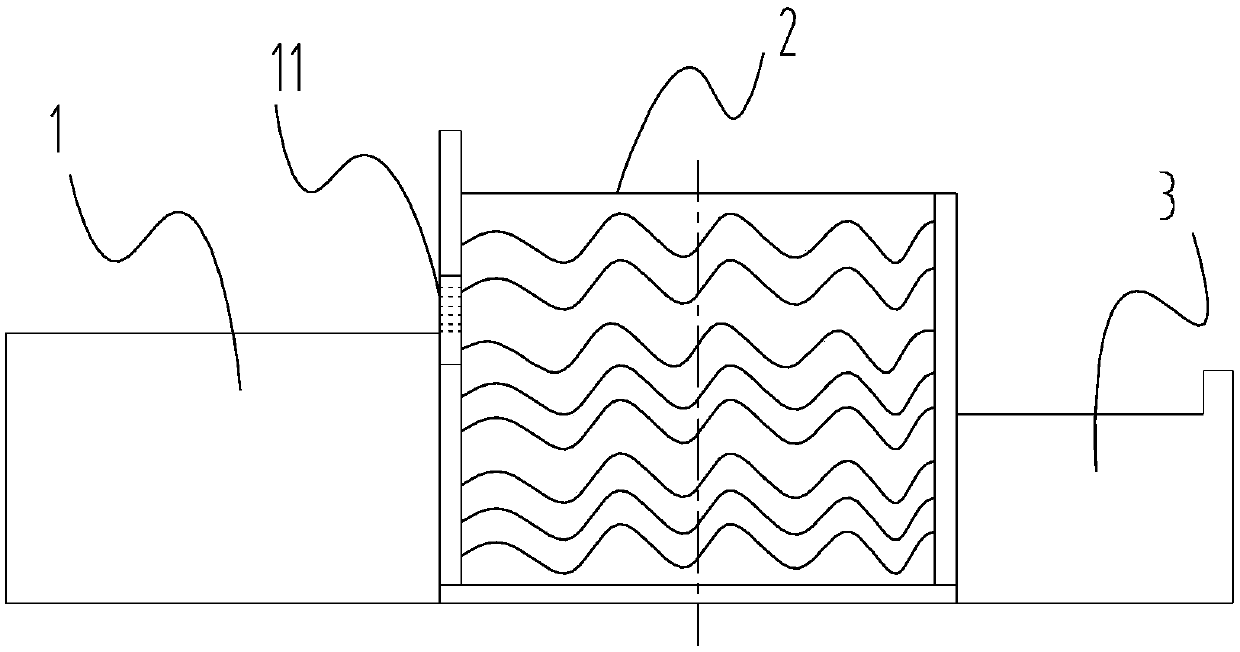

[0019] The present invention is as Figure 1-3 As shown, it includes a first reservoir 1, a second reservoir 2 and a third reservoir 3 connected in sequence;

[0020] The connection side of the second reservoir 2 and the first reservoir 1 is higher than the side of the second reservoir 2 and the third reservoir 3;

[0021] A plurality of filter holes 11 are provided on the side wall connecting the second reservoir 2 and the first reservoir 1 , and the filter holes 11 are located near the top of the first reservoir 1 .

[0022] A part of the settled solids settles to the bottom of the second reservoir 2, and the other part floats on the top of the second reservoir 2; the trace solids are in the middle position, and are filtered through the filter holes 11 set obliquely; Activated carbon can be set in the hole 11; the solids floating on the top flow into the third reservoir 3 along with the water flow; the water in the first reservoir 1 can be recycled again after standing.

...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap