LNOI-based optical waveguide reverse wedge-shaped spot coupler and preparation method thereof

An optical waveguide, wedge-shaped mode technology, applied in the coupling of optical waveguides, optical waveguides, light guides, etc., can solve the problems of not reaching the optimal transmittance size, no significant improvement, etc., to improve the mode spot matching degree, Efficient coupling and integration-friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

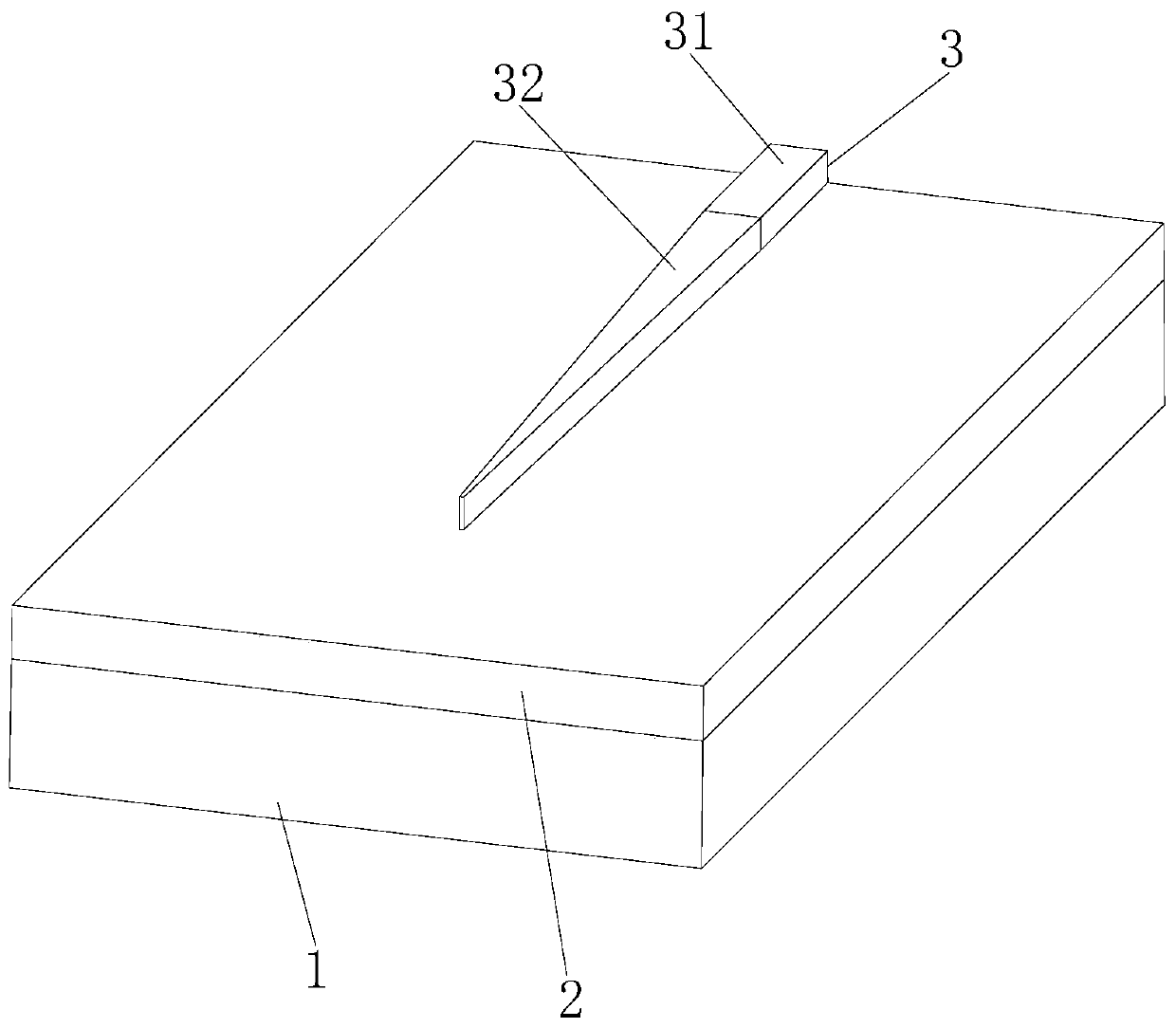

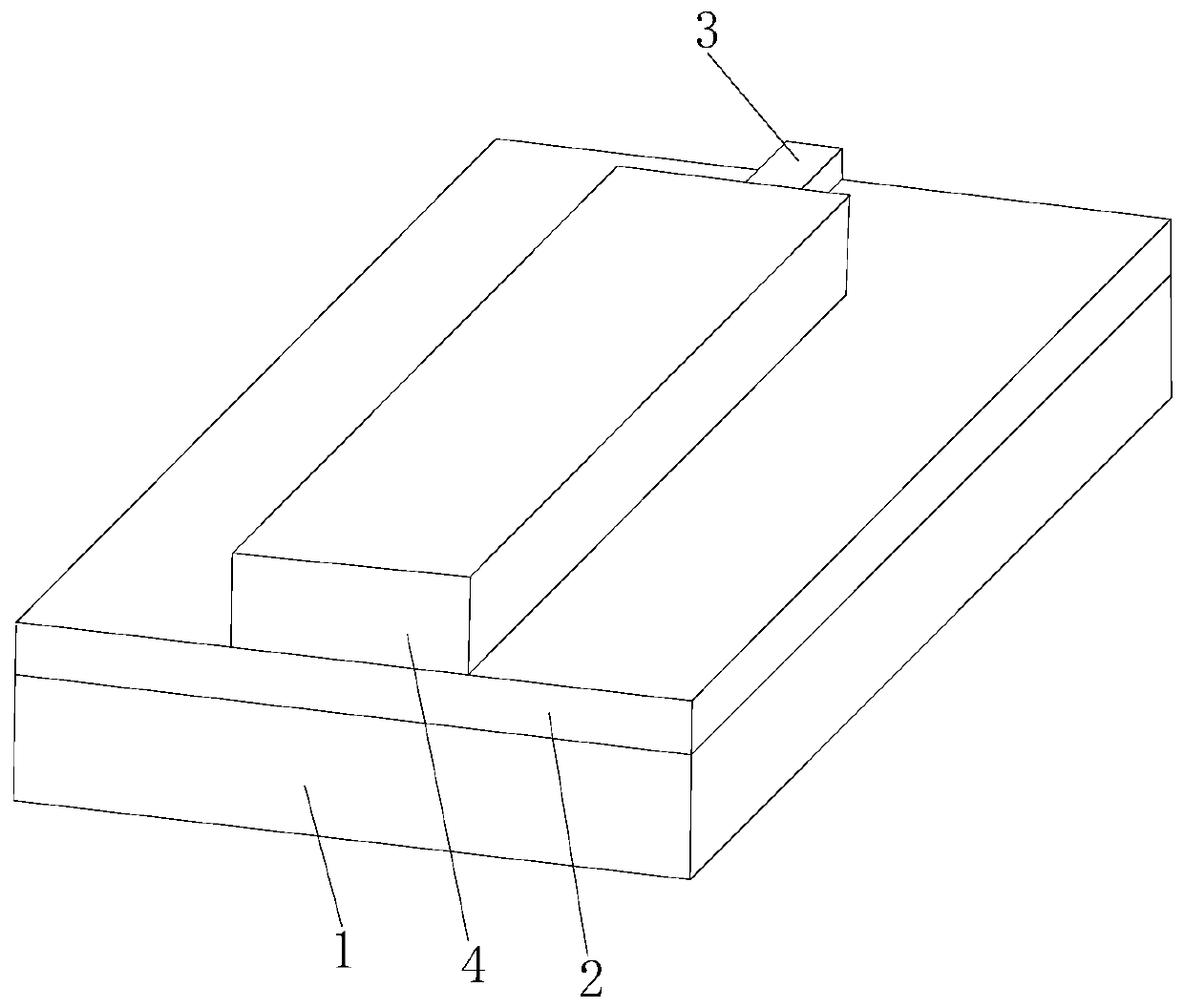

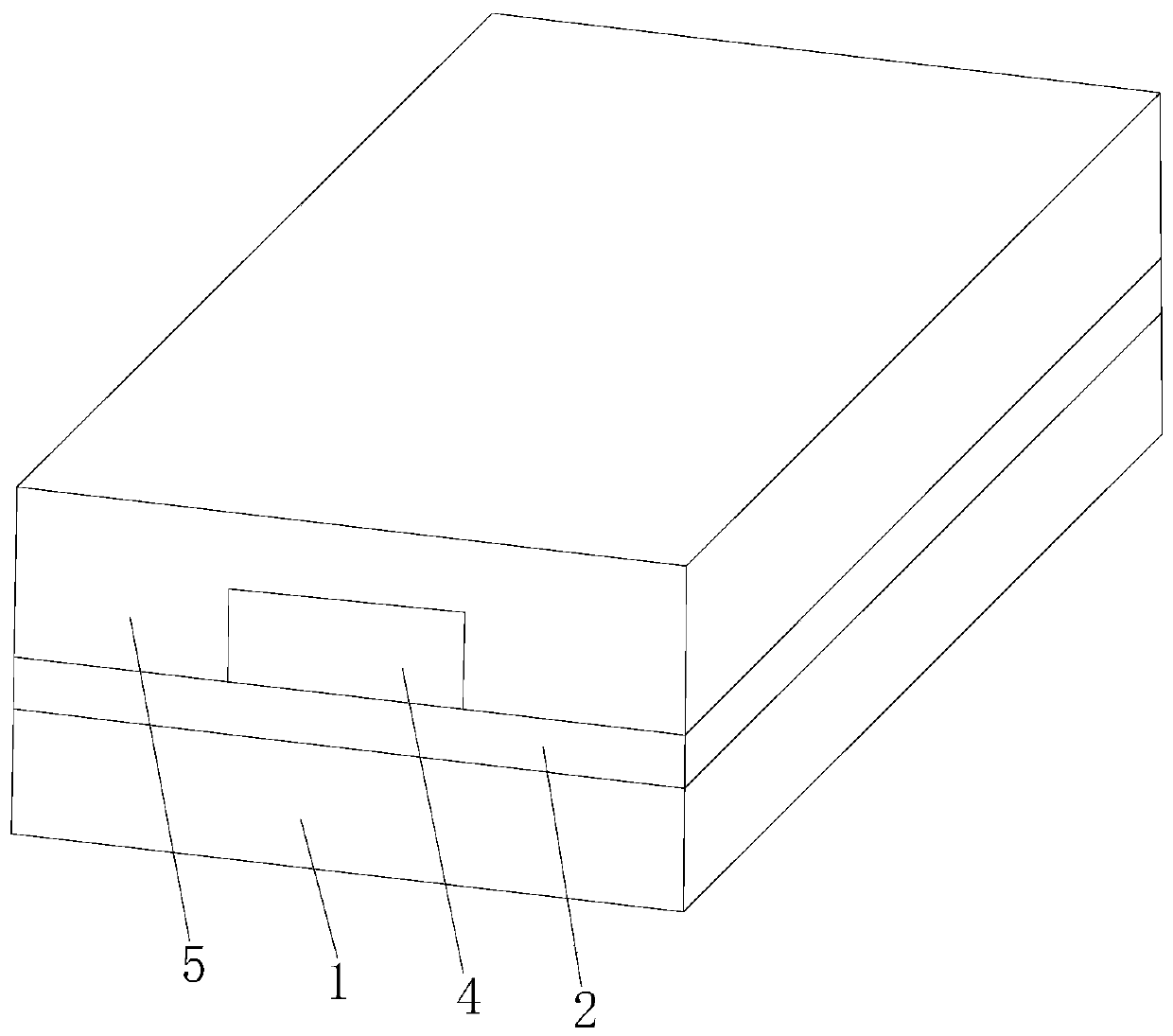

[0037] The invention provides an LNOI-based optical waveguide reverse wedge mode spot coupler and its preparation method. One end of the reverse wedge structure is the cross-sectional size of the single-mode waveguide calculated according to the single-mode conditions, and the other end is the lithium niobate micro-nano processing institute. The minimum line width that can be achieved; on the upper circumference of the reverse wedge structure (the first waveguide core layer), deposit a layer with the highest central refractive index and a gradually decreasing refractive index along the radial direction (light propagation direction) with a gradient change The thin film layer acts as the second waveguide core layer; ordinary single-mode waveguides have a strong confinement effect on light, and the mode field is confined to the center of the waveguide and propagates forward. As the light propagates forward, the width of the waveguide begins to decrease slowly , the confinement eff...

Embodiment 1

[0055] The invention provides an LNOI-based optical waveguide reverse wedge mode spot coupler and a preparation method thereof, including:

[0056] Step 1. Select the LNOI substrate, the structure of which is that the underlying supporting substrate layer 1 is a 500 μm Si layer, and the intermediate insulating layer is 2 μm thick SiO 2 layer, the top layer is a 500 nm thick LN layer. Using insulating layer SiO 2 The large refractive index difference between the LN layer and the LN layer achieves a strong confinement of the transmitted light in the waveguide core layer.

[0057] Step 2. Clean the LNOI substrate. After the LNOI substrate is cut according to the required direction and size, foreign particles and organic oil will adhere to the surface of the wafer, which must be cleaned;

[0058] The specific cleaning is as follows: first put the LNOI substrate into the acetone solution and alcohol solution in sequence, use an ultrasonic cleaner to oscillate and remove large par...

Embodiment 2

[0065] The invention provides an LNOI-based optical waveguide reverse wedge mode spot coupler and a preparation method thereof, including:

[0066] Step 1. Select the LNOI substrate, whose structure is a 400 μm LN layer at the bottom support layer, and the intermediate insulating layer is 2 μm thick SiO 2 layer, and the top layer is a 400 nm thick LN layer. Using insulating layer SiO 2 The large refractive index difference between the LN layer and the LN layer strongly confines the transmitted light in the waveguide core layer;

[0067] Step 2, cleaning the LNOI substrate. After the LNOI substrate is cut according to the required direction and size, impurity particles and organic oil will adhere to the surface of the wafer, which must be cleaned;

[0068] The specific cleaning is as follows: first put the LNOI substrate into the acetone solution and alcohol solution in sequence, use an ultrasonic cleaner to oscillate and remove large particles of dirt on the surface, then u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com