Spiral-flow type turbulence inhibitor with buffering balls for continuous casting tundish

A suppressor and swirl-type technology, applied in the field of turbulence suppressors, can solve the problems of not fully conforming to hydrodynamic characteristics, easily damaged blocks, high inclusions, etc., and achieve the effect of reducing splash, simple structure and high degree of purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0028] Example 1:

[0029] The depth of the molten steel pool in the middle of a steel plant is 1200mm, the inner diameter of the shroud is 100mm, the insertion depth of the shroud is 500mm, and the height from the shroud outlet to the inner bottom of the tundish is 700mm.

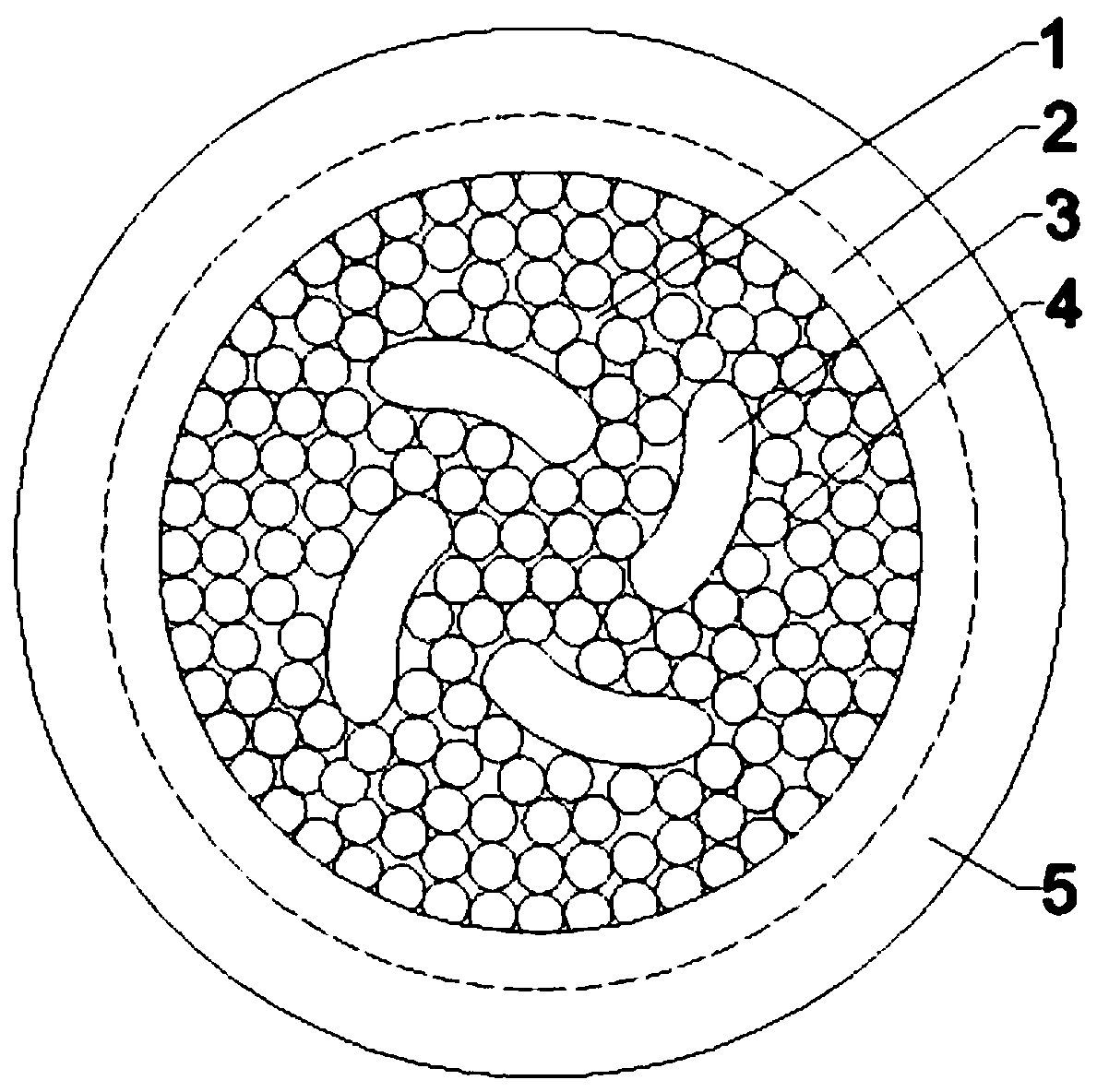

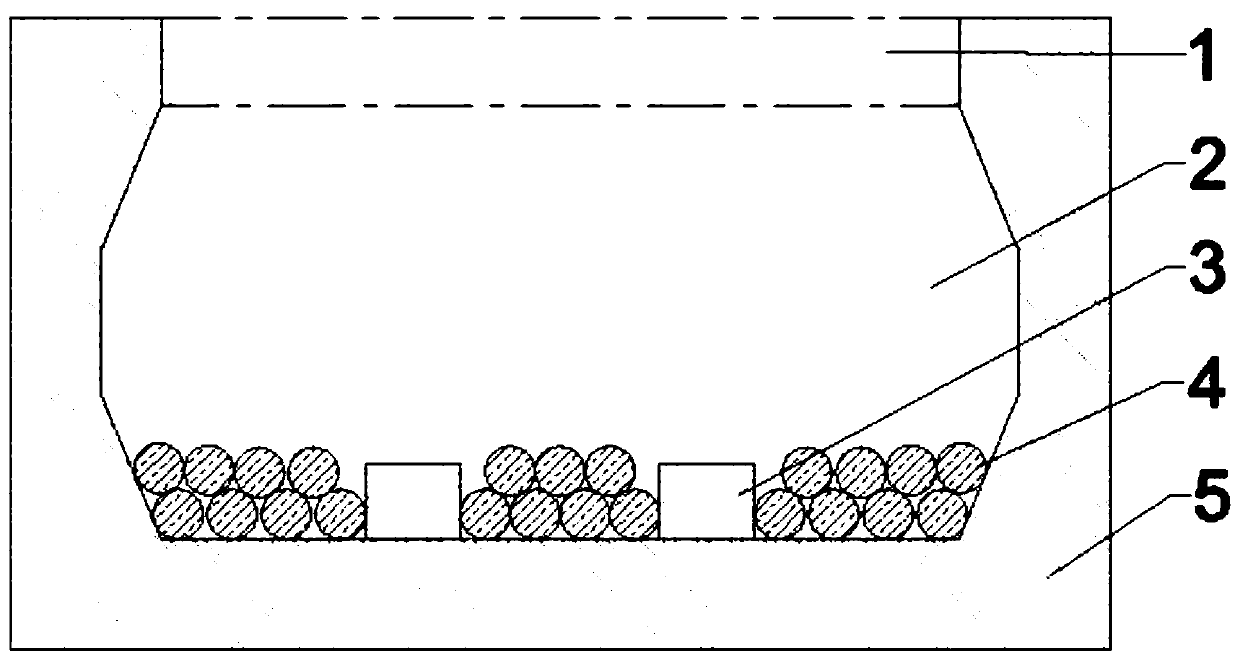

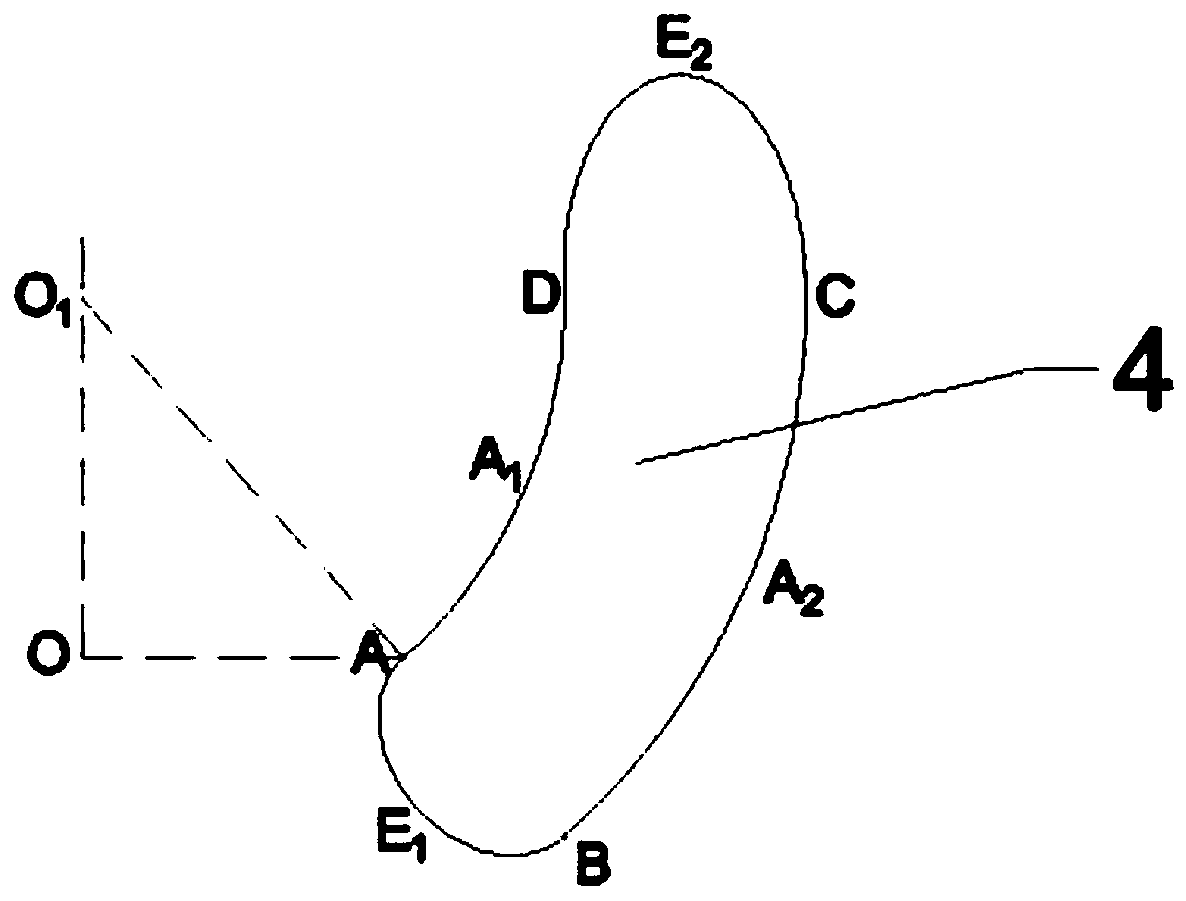

[0030] The four shallow bow-shaped three-dimensional stoppers 3 arranged in a ring around the center of the bottom surface are 20 mm high, and the bottom surface of the cavity is evenly filled with buffer balls with a diameter of 10 mm. The suppressor body 5 is embedded and installed on the bottom 6 of the continuous casting tundish, located directly below the long nozzle 7 of the tundish, its axis coincides with the axis of the long nozzle 7, and the inner bottom surface of the suppressor body 5 is on the same plane superior.

[0031] The cavity in the suppressor body 5 is 140 mm high, the upper opening 1 has a diameter of 300 mm and a height of 28 mm; the cavity 2 below the opening has a hexagonal or oc...

Example Embodiment

[0035] Example 2:

[0036] The depth of the molten steel pool in the middle of a steel plant is 1200mm, the inner diameter of the shroud is 100mm, the insertion depth of the shroud is 500mm, and the height from the shroud outlet to the inner bottom of the tundish is 700mm.

[0037] The four shallow bow-shaped three-dimensional stoppers 3 arranged in a ring around the center of the bottom surface are 50 mm high, and the bottom surface of the cavity is evenly filled with buffer balls with a diameter of 30 mm. The suppressor body 5 is embedded and installed on the bottom 6 of the continuous casting tundish, located directly below the long nozzle 7 of the tundish, its axis coincides with the axis of the long nozzle 7, and the inner bottom surface of the suppressor body 5 is on the same plane superior.

[0038] The cavity in the suppressor body 5 is 233.33mm high, the upper opening 1 has a diameter of 600mm, and the height is 46.67mm; the cavity 2 below the opening has a hexagonal...

Example Embodiment

[0042] Example 3:

[0043] The depth of the molten steel pool in the middle of a steel plant is 1200mm, the inner diameter of the shroud is 100mm, the insertion depth of the shroud is 500mm, and the height from the shroud outlet to the inner bottom of the tundish is 700mm.

[0044] The four shallow bow-shaped three-dimensional stoppers 3 arranged in a ring around the center of the bottom surface are 40 mm high, and the bottom surface of the cavity is evenly filled with buffer balls with a diameter of 24 mm. The suppressor body 5 is embedded and installed on the bottom 6 of the continuous casting tundish, located directly below the long nozzle 7 of the tundish, its axis coincides with the axis of the long nozzle 7, and the inner bottom surface of the suppressor body 5 is on the same plane superior.

[0045] The cavity in the suppressor body 5 is 200.67mm high, the upper opening 1 has a diameter of 500mm, and the height is 40.13mm; the cavity 2 below the opening has a hexagonal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap