Ceramic structure member and preparation method thereof

A technology for structural parts and ceramics, applied in the field of ceramic structural parts and their preparation, can solve the problems of high production cost, deformation, low yield and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

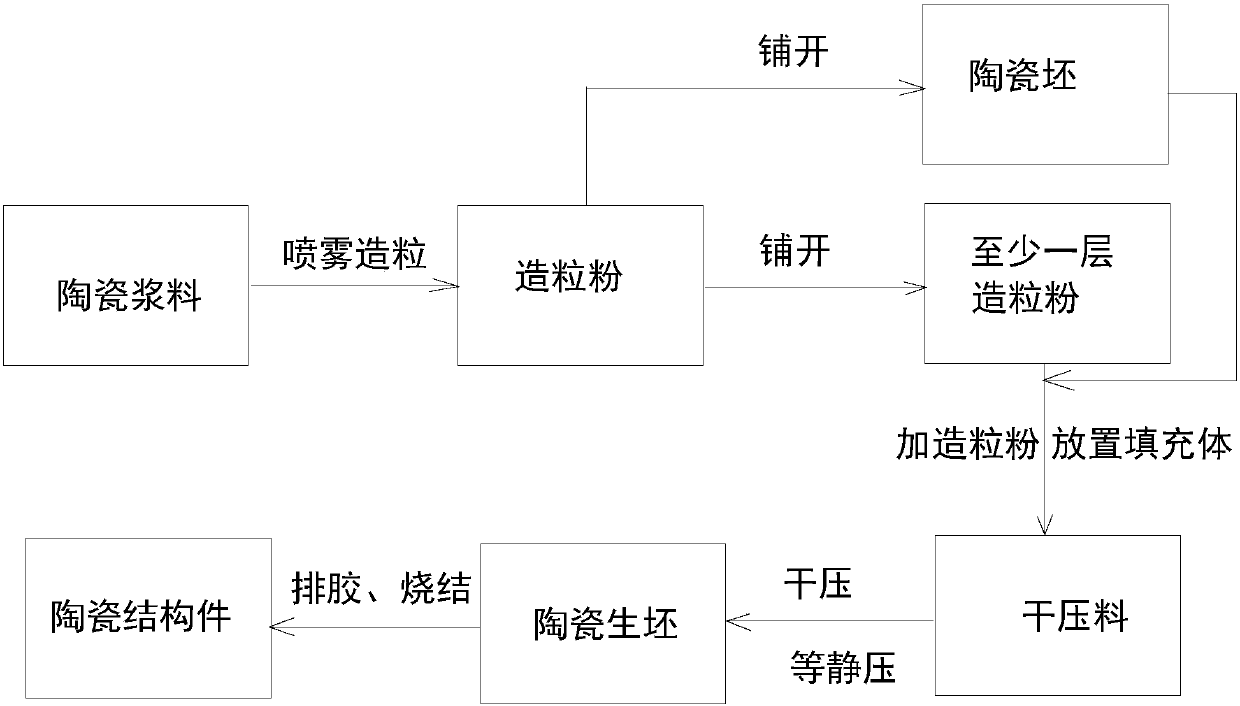

[0032] Please refer to figure 1 , the present invention provides a kind of preparation method of ceramic structure, it comprises the steps:

[0033] S1, take the ceramic slurry, spray and granulate to obtain granulated powder;

[0034] S2. Take the graphite filling body, and pre-embed the graphite filling body in a specific position inside the granulated powder to form a dry compact; or, press part of the granulated powder into a ceramic blank, and place the graphite filling body Placed at a specific position of the ceramic blank, and then spread the granulated powder on the ceramic blank to cover the graphite filler to form a dry compact;

[0035] S3, performing dry pressing on the dry pressing material, and then performing isostatic pressing treatment to obtain a ceramic green body;

[0036] S4. Debinding and sintering the ceramic green body to obtain a ceramic structural part with channels or through holes inside. When the temperature reaches above 300°C, the graphite fi...

Embodiment 1

[0058] This embodiment provides a method for preparing a ceramic structure, which includes the following steps:

[0059] Take, 99.5 parts of yttrium-stabilized zirconia powder, 0.05 parts of alumina, 0.5 parts of CMC, 0.5 parts of PEG, 4.5 parts of PVA, and 70 parts of deionized water, and mix the above raw materials by ball milling to obtain ceramic slurry, which is obtained by spray granulation. Granulating powder; get 100 parts of graphite powder, 70 parts of solvent, 4 parts of dispersing agent, 15 parts of binding agent; The graphite powder wherein is spherical graphite powder, and solvent wherein is made with alcohol and methyl ethyl ketone with 1:1 volume ratio, The dispersant is made up of fish oil and phosphate ester at a ratio of 1:1, and the binder is polyvinyl butyral. The method of using the above-mentioned filler to prepare a filler is: S1, mixing graphite powder, solvent, dispersant and binder together, and mixing uniformly by ball milling to form a slurry; S2, ...

Embodiment 2

[0061] This embodiment provides a method for preparing a ceramic structure, which includes the following steps:

[0062] Take 80 parts of yttrium-stabilized zirconia powder, 20 parts of alumina, 0.5 part of CMC, 0.5 part of PEG, 6 parts of PVA, and 90 parts of deionized water, and mix the above raw materials by ball milling to prepare a ceramic slurry, which is obtained by spray granulation Granulated powder: 100 parts of graphite powder, 60 parts of solvent, 5.5 parts of dispersant, and 15 parts of binder; wherein the graphite powder is spherical graphite powder, and the impurity content is less than 0.1%. The solvent is alcohol and methyl ethyl ketone in a volume ratio of 1:1, the dispersant is fish oil, and the binder is polyvinyl butyral. The method of using the above-mentioned filler to prepare a filler is: S1, mixing graphite powder, solvent, dispersant and binder together, and mixing uniformly by ball milling to form a slurry; S2, mixing the above-mentioned slurry in D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com