Dyed cloth bundling equipment

A technology for dyeing cloth and equipment, which is applied in the directions of removing liquid/gas/vapor by squeezing rollers, removing liquid/gas/vapor by scraping method, and processing textile material carriers, etc. , bundling, dye dripping from dyed cloth, waste of time for dyeing and drying, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

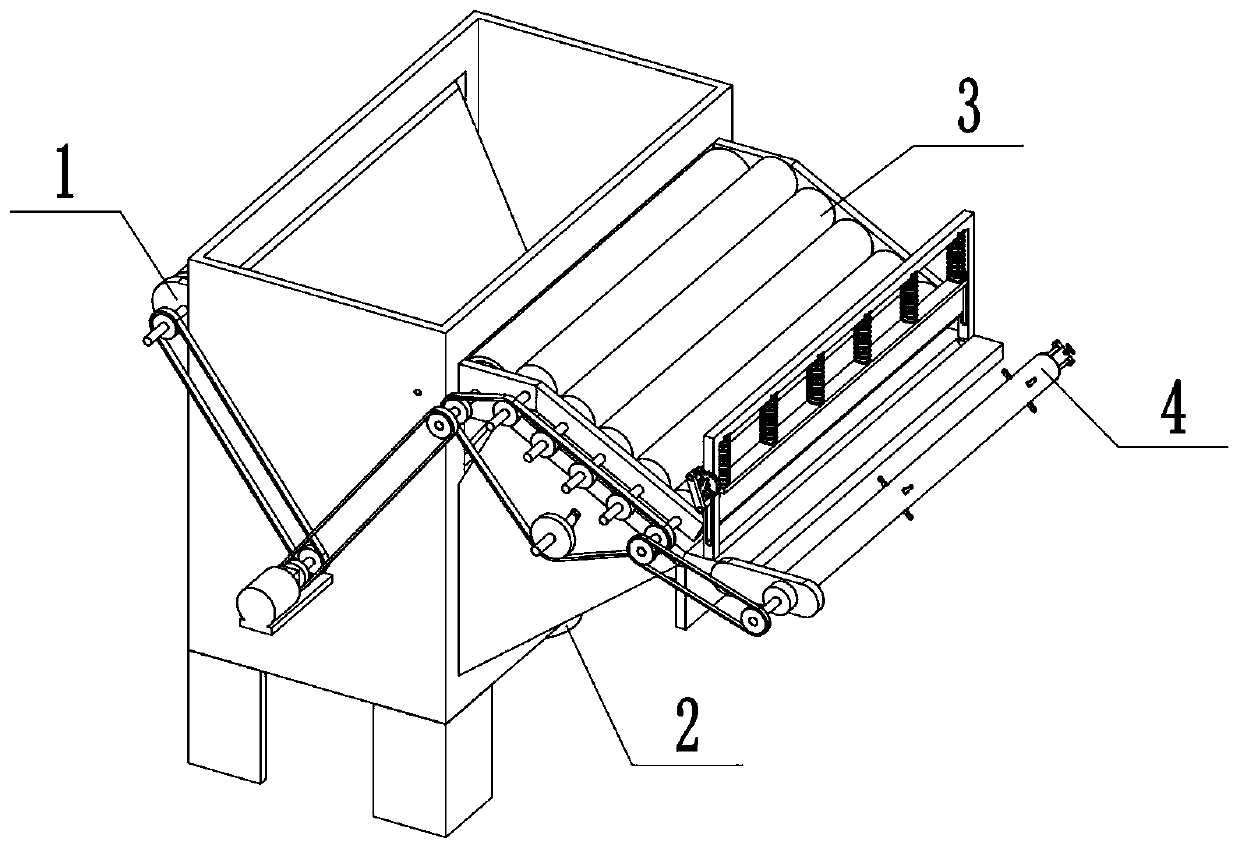

[0037] Combine below Figure 1-22 In this embodiment, a dyeing cloth bundling equipment includes a dyeing cloth assembly 1, a stirring assembly 2, a drying assembly 3 and a bundling assembly 4, and the dyeing cloth assembly 1 and the stirring assembly 2 are Connection, the drying assembly 3 is connected with the dyeing assembly 1, and the bundling assembly 4 is connected with the drying assembly 3.

specific Embodiment approach 2

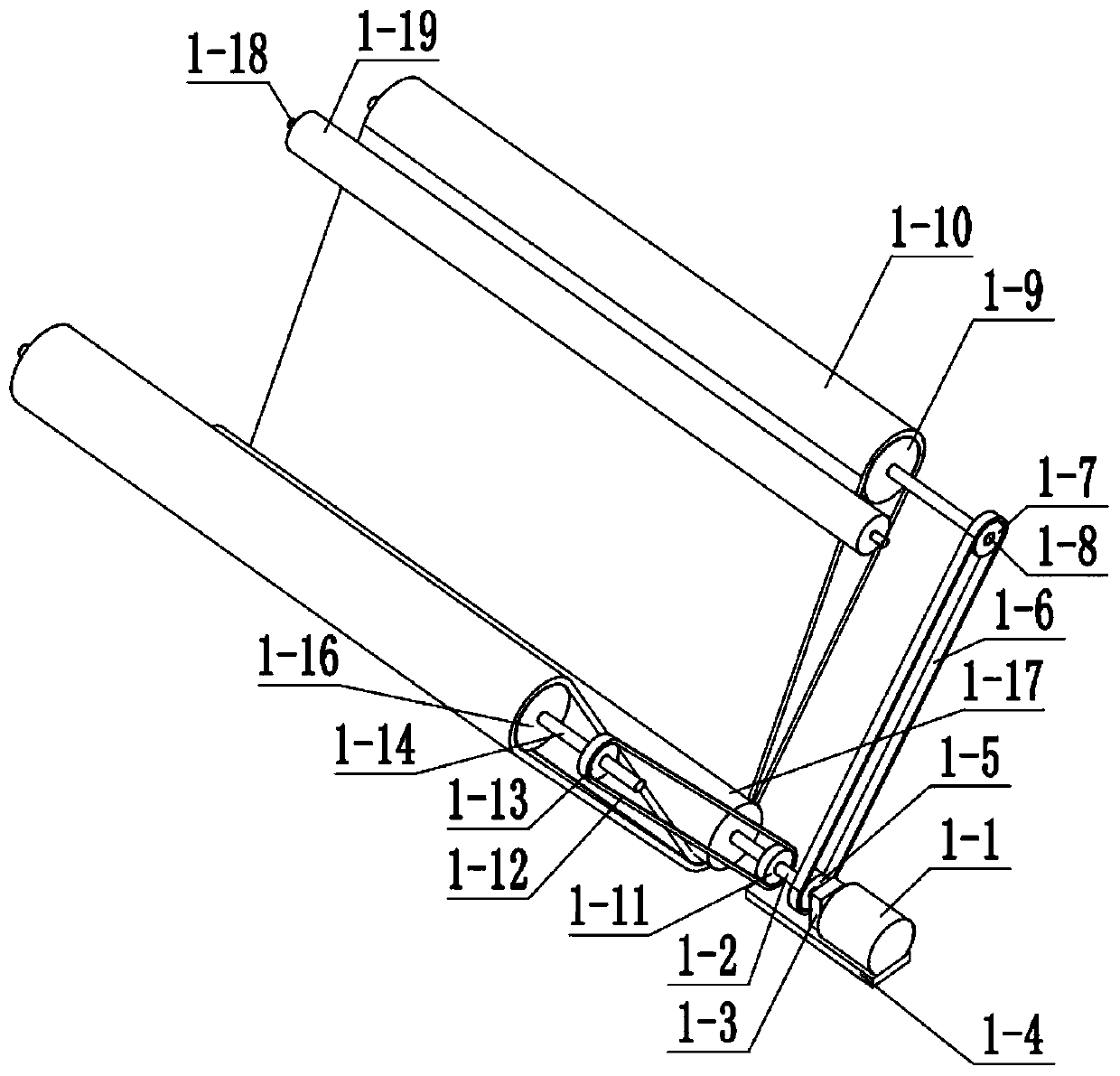

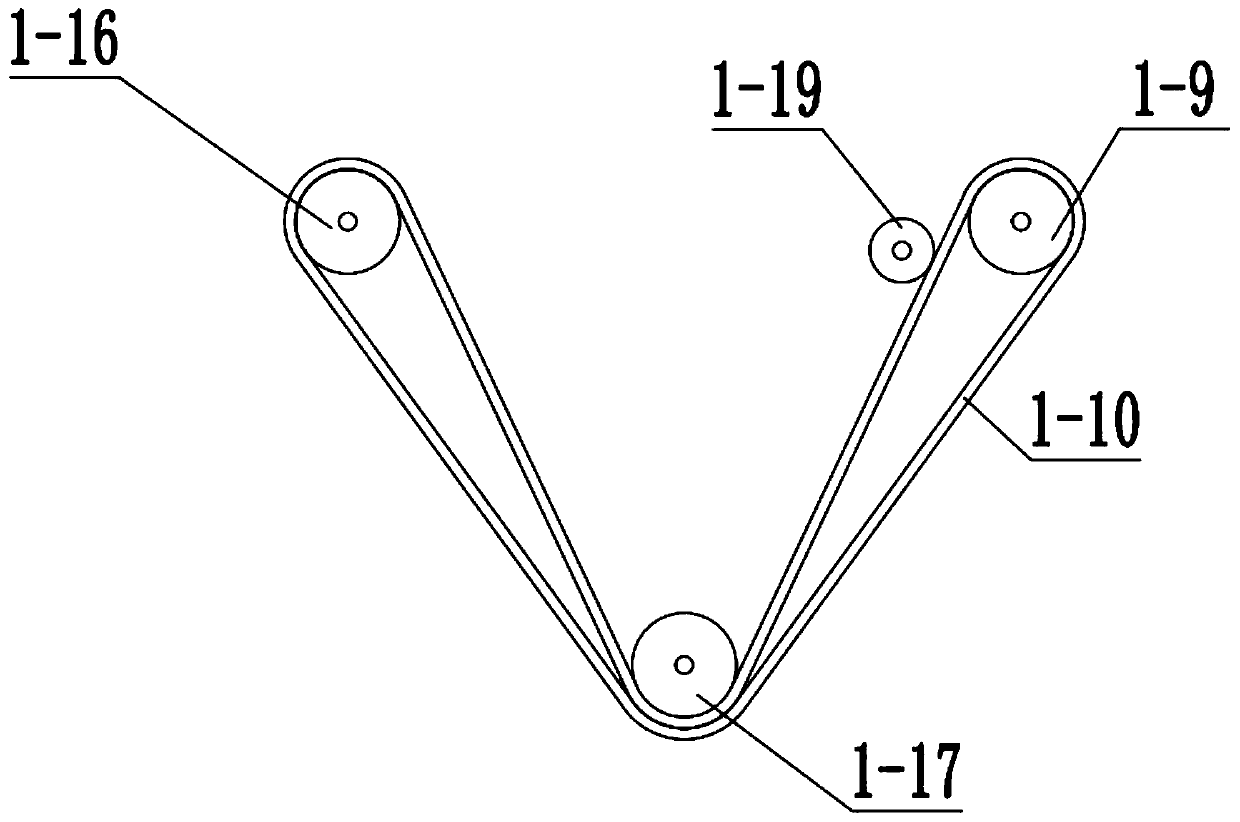

[0039] Combine below Figure 1-22 In this embodiment, this embodiment will further explain Embodiment 1. The dyeing cloth assembly 1 includes a motor I 1-1, a motor I shaft 1-2, a motor I shaft bracket 1-3, a motor I bracket 1-4, Dyeing sprocket Ⅰ1-5, dyeing chain Ⅰ1-6, dyeing sprocket Ⅱ1-7, dyeing shaft Ⅰ1-8, dyeing roller Ⅰ1-9, conveyor belt 1-10, dyeing sprocket Ⅲ1- 11. Dyeing chain Ⅱ1-12, dyeing sprocket Ⅳ1-13, dyeing shaft Ⅱ1-14, dyeing shaft Ⅱ support 1-15, dyeing roller Ⅱ1-16, dyeing roller Ⅲ1-17, extrusion Water shaft 1-18 and squeeze roller 1-19, motor I 1-1 is connected with motor I shaft 1-2, motor I 1-1 is connected with motor I bracket 1-4, motor I shaft 1-2 is connected with motor I Shaft support 1-3 is rotationally connected, motor I shaft support 1-3 is connected with motor I support 1-4, motor I shaft 1-2 is connected with dyeing cloth sprocket I1-5, dyeing cloth sprocket I1-5, Dyeing chain Ⅰ1-6, dyeing sprocket Ⅱ1-7 are connected by sprocket chain, dyeing s...

specific Embodiment approach 3

[0041] Combine below Figure 1-22 This embodiment, this embodiment will further explain the first embodiment, the stirring assembly 2 includes motor II 2-1, motor II bracket 2-2, dyeing chamber bottom plate 2-3, dyeing chamber 2-4, motor II shaft 2-5. Stirring sprocket Ⅰ 2-6, stirring chain 2-7, stirring sprocket Ⅱ 2-8, stirring shaft 2-9 and stirring blade 2-10, motor Ⅱ 2-1 is connected with motor Ⅱ bracket 2-2, The motor II bracket 2-2 is connected to the dyeing chamber bottom plate 2-3, the dyeing chamber bottom plate 2-3 is connected to the dyeing chamber 2-4, the motor I shaft 1-2, and the water squeezing shaft 1-18 are all connected to the dyeing chamber 2- 4 Rotation connection, motor I support 1-4, dyeing shaft II support 1-15 are connected with dyeing chamber 2-4, motor II shaft 2-5 is connected with motor II 2-1, motor II shaft 2-5 is connected with Dyeing room bottom plate 2-3 is rotationally connected, motor II shaft 2-5 is connected with agitating sprocket I2-6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com