Natural rubber block grabbing fixture

A natural rubber and fixture technology, applied in chucks, manufacturing tools, manipulators, etc., can solve the problems of odor, limited labor force, low production efficiency, etc., to ensure the quality of rubber blocks and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

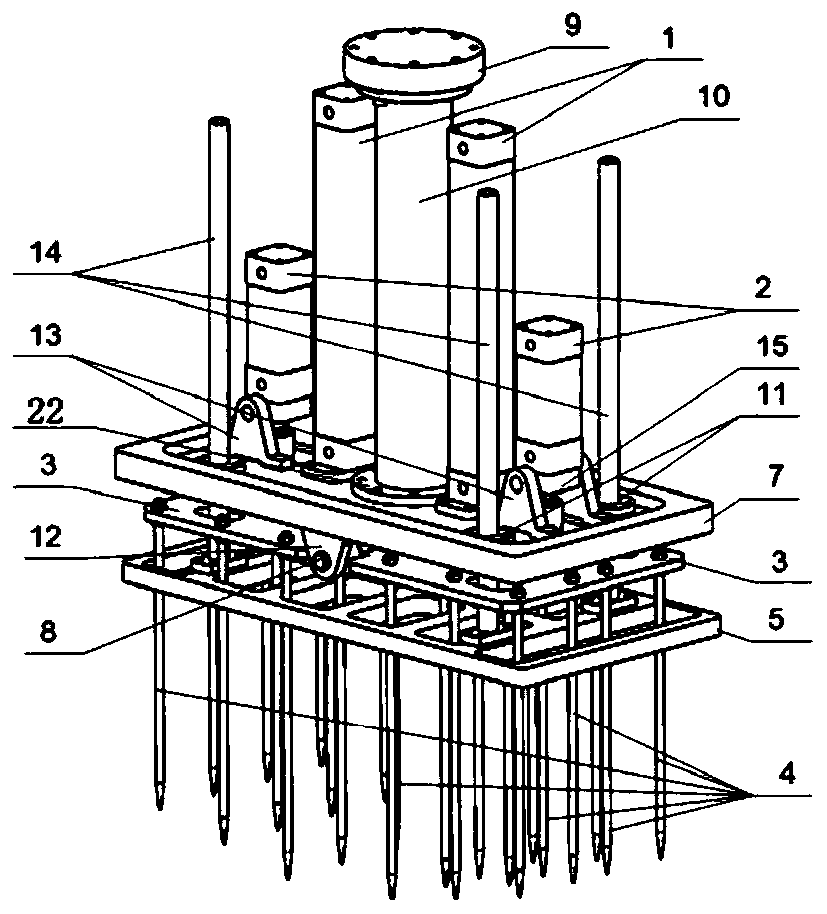

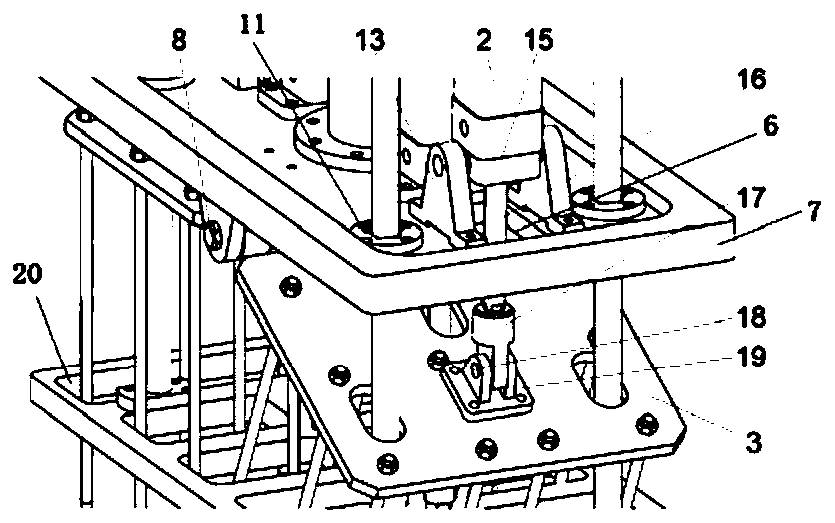

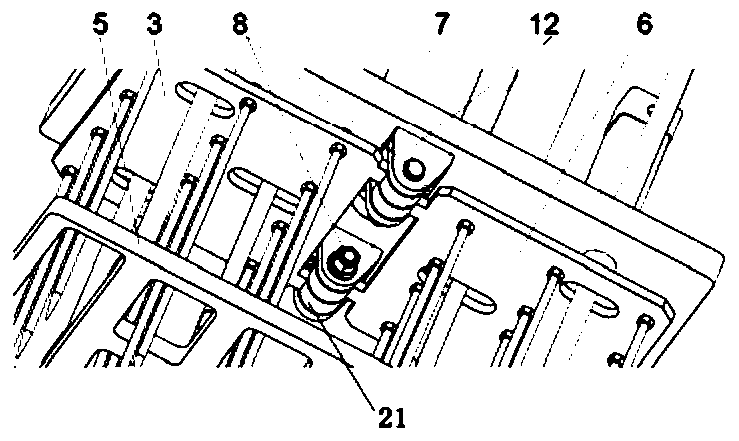

[0016] like Figure 1 ~ Figure 3 The shown natural rubber block grabbing fixture includes a connecting pipe 10 that can be installed on the hanging arm of the robot 23, a rectangular base plate 7 installed at the bottom end of the connecting pipe, two rectangular rotating plates 3 symmetrically arranged below the base plate, and arranged on The rectangular push plate 5 below the rectangular rotating plate.

[0017] Two pairs of lugs 12 and rotating shafts 8 mounted on the lugs are installed symmetrically at the midline position of the bottom surface of the base plate, and round holes and elongated holes 6 are arranged symmetrically in the middle of both sides of the base plate and are arranged on both sides of the elongated holes. The substrate support 13 on the side is equipped with a rotatable cylinder base 15 and a rotating plate cylinder 2 vertically installed on the cylinder base on the base plate support, and the cylinder rod 16 of the rotating plate cylinder passes thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com