Optical components and optical films

A technology of optical elements and optical films, applied in optical elements, optics, instruments, etc., can solve problems such as deterioration of captured image quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, optical lenses according to some embodiments of the present invention will be described. In addition, the embodiments described below do not limit the inventions covered by the scope of the patent application, and not all elements and combinations thereof described in the embodiments are necessary for the invention to solve technical problems.

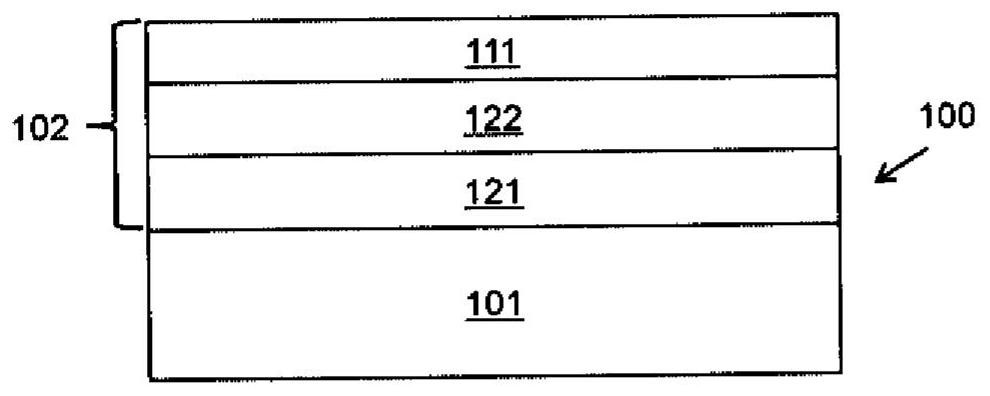

[0031] figure 1 The concept of the configuration of the optical lens according to the embodiment of the present invention is shown.

[0032] The optical lens 100 includes an optical lens body 101 and a multilayer film 102 that is an optical thin film formed on the surface of the optical lens body 101 . The multilayer film 102 is a plurality of films that overlap (laminate) each other.

[0033] The multilayer film 102 has both hydrophilic and anti-reflection functions. In the multilayer film 102, the film of the first layer (uppermost layer) is a hydrophilic film 111 which is a porous film. The film of the second...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com