Bridge machine dismantling and installation construction method in factory building bridge machine renewal project

A technology of installation method and construction method, which is applied in the directions of walking bridge crane, transportation and packaging, crane, etc., can solve the problems of increased cost, large external size, affecting the safe operation of the power station, etc., and achieves cost saving, convenient operation, and process flow. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] This embodiment is a construction method for dismantling and installing bridge cranes in a factory building bridge crane renewal project, including a method for dismantling old bridge cranes and a method for installing new bridge cranes.

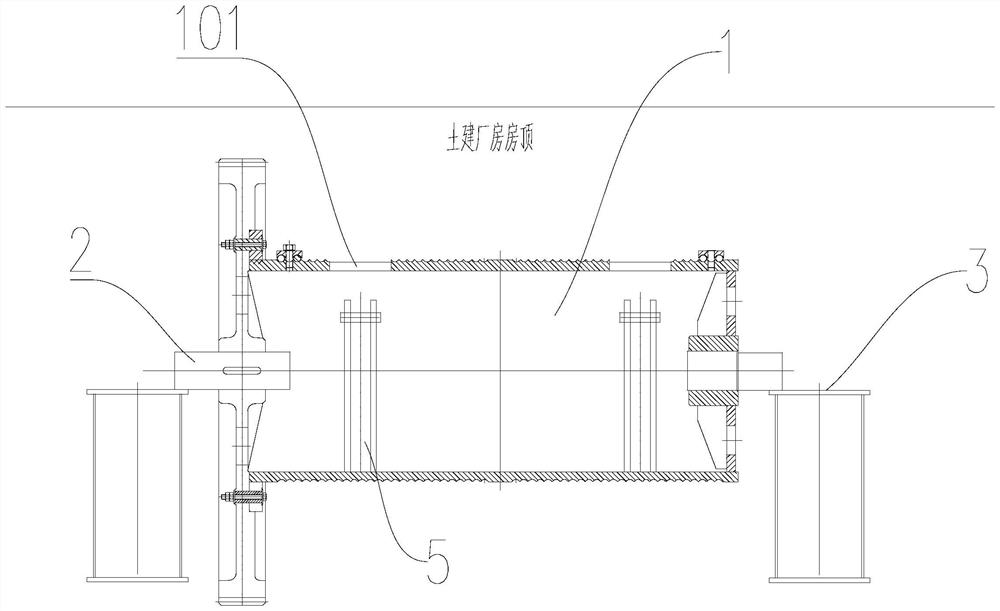

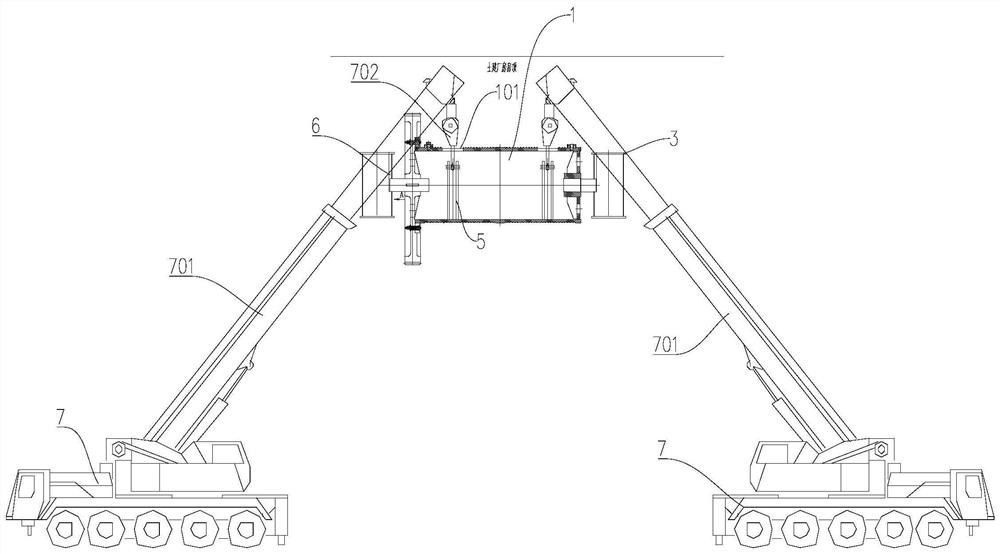

[0029] Such as figure 1 , figure 2 As shown, the steps of the old bridge machine disassembly method in this embodiment are as follows:

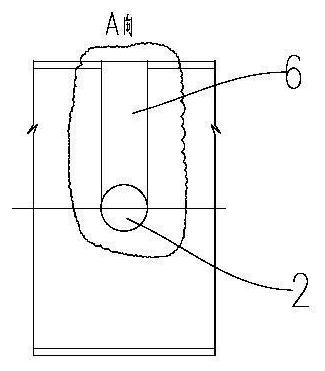

[0030] Disassemble and lift off the main lifting parts and the connecting parts at both ends of the drum 1, so that the drum 1 is supported on the top surface of the girder 3 of the old bridge machine through the rotating shaft 2 at both ends; at this time, the drum 1 needs to be fixed with a fixing piece , preventing the reel 1 from rolling on the girder 3 of the old bridge machine and affecting safety;

[0031] From the inside of the old bridge machine girder 3 on both sides of the factory building, gradually cut from top to bottom on the inside of the old bridge machine girder 3 to form a notch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com