A kind of polysilicon acrylate aluminum cerium flocculant and its preparation method and application

A polysilicon acrylic aluminum, flocculant technology, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of low heavy metal removal rate, few types of heavy metals, flocculant Large dosage and other problems, to achieve the effect of high removal rate of heavy metals, less dosage, and efficient removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

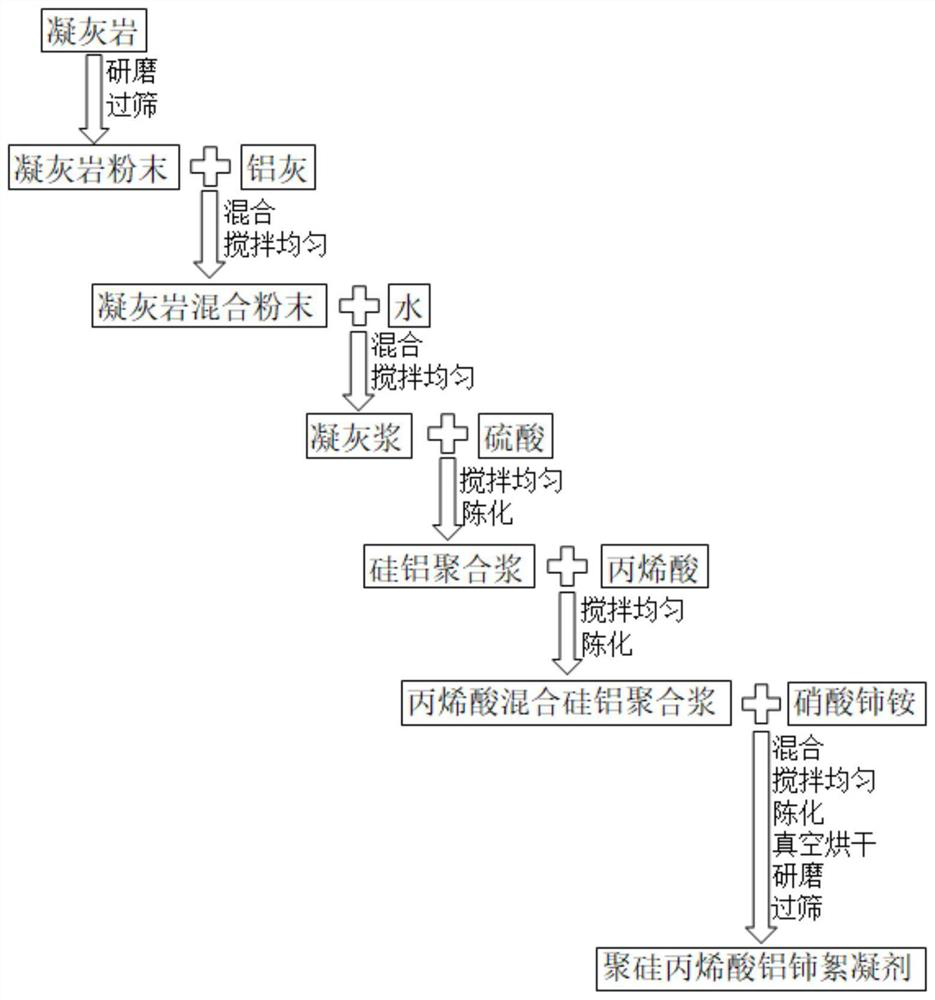

Method used

Image

Examples

Embodiment 1

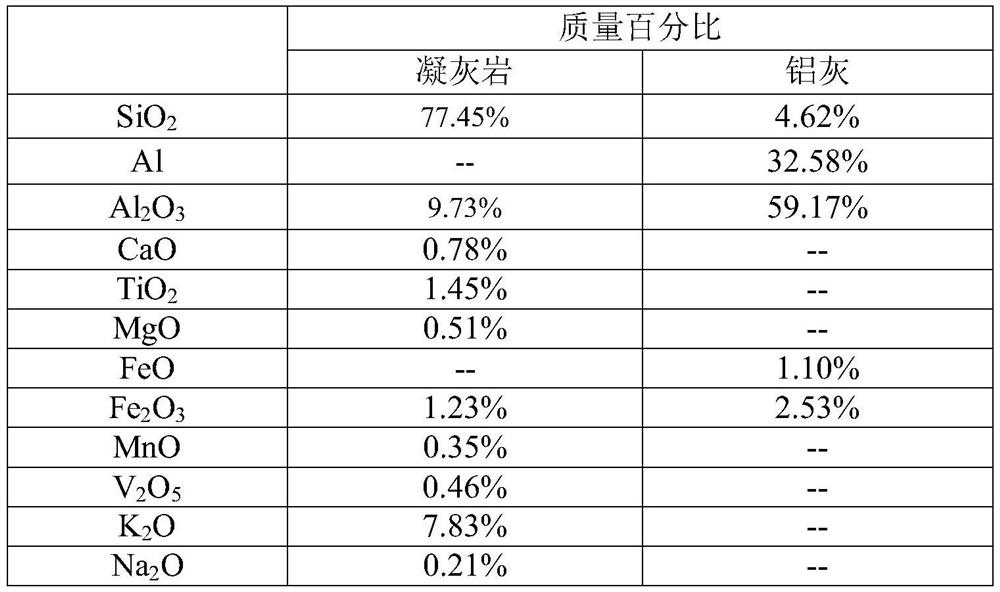

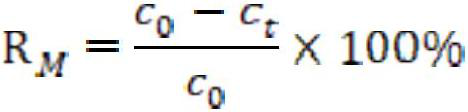

[0029] Example 1 The influence of aluminum ash and tuff powder mass ratio on the removal rate of heavy metals in the prepared flocculant adsorption water

[0030] The tuff is ground and passed through a 200-mesh sieve to obtain tuff powder. According to the mass ratio of 0.5:10, 0.7:10, 0.9:10, 1:10, 2:10, 3:10, 3.2:10, 3.5:10, 4:10, weigh aluminum ash and tuff powder respectively, mix and stir Evenly, nine groups of tuff mixed powder are obtained. According to the liquid-solid ratio of 0.6:1mL / mg, the mixed powder of water and tuff was weighed respectively, mixed and stirred evenly to obtain nine groups of tuff slurry. Add concentrated sulfuric acid to the nine groups of tuff slurry, stir evenly, make the slurry pH 1, and age for 3 hours to obtain nine groups of silicon-aluminum polymerization slurry. According to the volume ratio of acrylic acid and silicon-aluminum polymerization slurry of 10%, acrylic acid was added to the nine groups of silicon-aluminum polymerization s...

Embodiment 2

[0038] Example 2 Effect of the volume ratio of acrylic acid and silicon-aluminum polymerization slurry on the removal rate of heavy metals in the prepared flocculant adsorption water

[0039]Grind the tuff and pass through a 300-mesh sieve to obtain tuff powder. According to the mass ratio of 3:10, aluminum ash and tuff powder were weighed respectively, mixed and stirred evenly to obtain tuff mixed powder, and a total of nine groups of tuff mixed powder were weighed according to the same mass ratio. According to the liquid-solid ratio of 0.8:1mL / mg, the water and tuff mixed powder were weighed respectively, mixed and stirred evenly, and nine groups of tuff slurry were also obtained. Add concentrated sulfuric acid to the nine groups of tuff slurry respectively, stir evenly to make the pH of the slurry 1.5, and age for 4.5 hours to obtain the nine groups of silicon-aluminum polymerization slurry. According to the volume ratio of acrylic acid and silicon-aluminum polymerization ...

Embodiment 3

[0045] Example 3 The effect of the mass ratio of cerium ammonium nitrate and acrylic acid mixed silicon-aluminum polymerization slurry on the removal rate of heavy metals in the prepared flocculant adsorption water

[0046] The tuff is ground and passed through a 400-mesh sieve to obtain tuff powder. Weigh aluminum ash and tuff powder respectively according to the mass ratio of 3:10, mix and stir evenly to obtain tuff mixed powder, and weigh nine groups of tuff mixed powder according to the same mass ratio. According to the liquid-solid ratio of 1:1mL / mg, the mixed powder of water and tuff was weighed respectively, mixed and stirred evenly, and nine groups of tuff slurry were also obtained. Add concentrated sulfuric acid to the nine groups of tuff slurry respectively, stir evenly to make the slurry pH 2, and age for 6 hours to obtain nine groups of silicon-aluminum polymerization slurry. According to the volume ratio of acrylic acid and silicon-aluminum polymerization slurry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com