Parallel heating type sectional heating structure and low-temperature smoking set using same

A heating-type, low-temperature technology, applied in the field of low-temperature cigarettes, can solve the problems of reduced nicotine content, high smoke temperature, and affecting the taste, and achieve the effects of stable release, good thermal stability, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

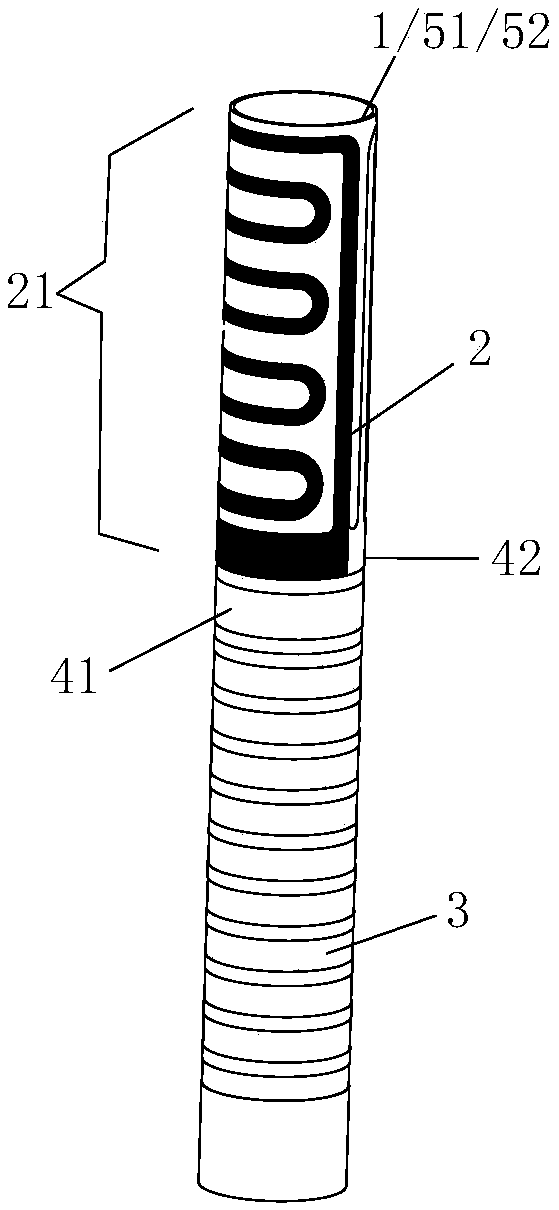

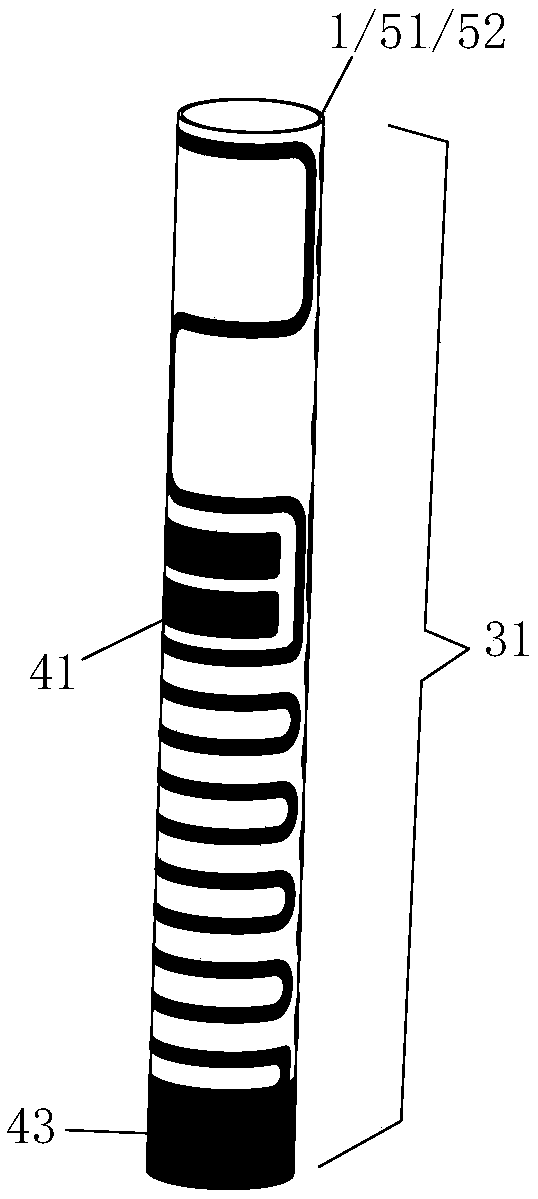

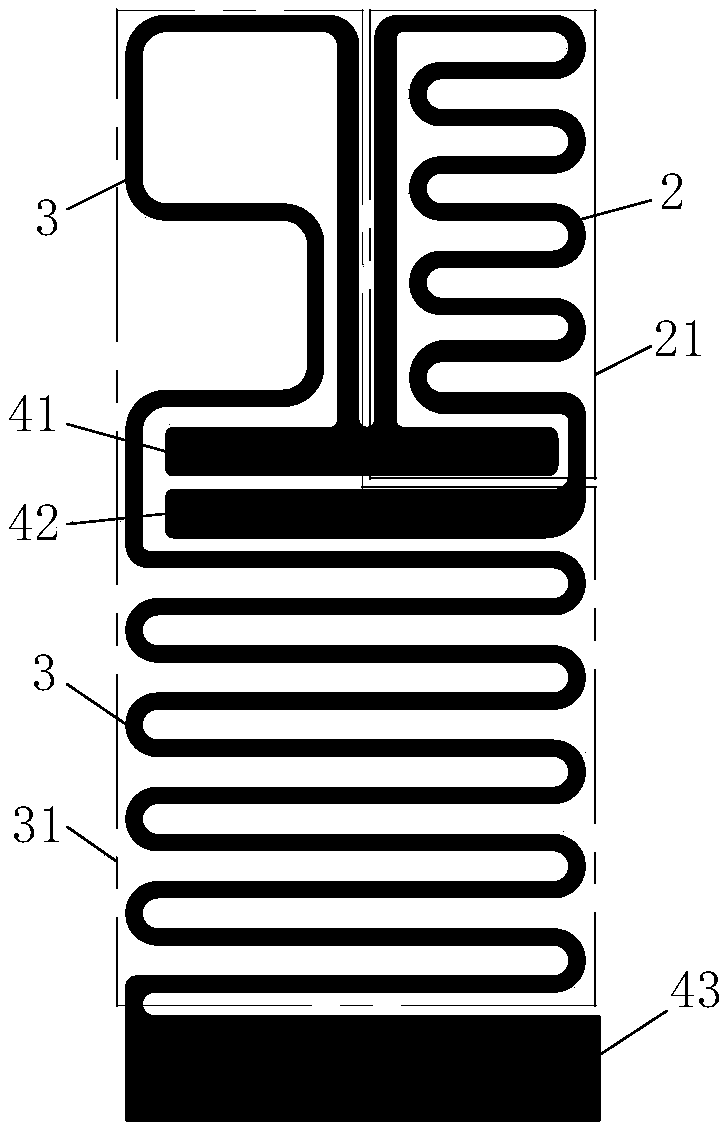

[0039] see figure 1 and figure 2 , the parallel heating type segmental heating structure in the illustration is a preferred solution of the present invention, its main body is a heating substrate 1, and several heating components are distributed on the heating substrate 1, and the heating components are heating resistance wires that utilize electricity to generate heat. Or a resistance sheet, heat and bake the smoke-generating medium in contact with the heat-generating substrate 1, and heat the smoke-generating medium in a non-combustible manner to generate smoke.

[0040] The smoking medium includes but is not limited to smokeable materials such as low-temperature cigarettes, tobacco or e-liquid used in low-temperature smoking appliances. The heating substrate 1 referred to above can be a heating tube or a heating core, and the heating tube can be a ceramic tube or a metal tube, and the inside of the tube cavity contains the smoking medium, and the heating components arrang...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap