A flexible display panel, its manufacturing method, and a flexible display terminal

A flexible display and panel technology, used in semiconductor/solid-state device manufacturing, identification devices, instruments, etc., can solve the problems of interlayer peeling, black spots on the screen, and easy breakage of the film encapsulation layer, and achieves dispersion of bending stress, blocking The effect of propagation of cracks, reduction of the probability of fracture and interlayer debonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

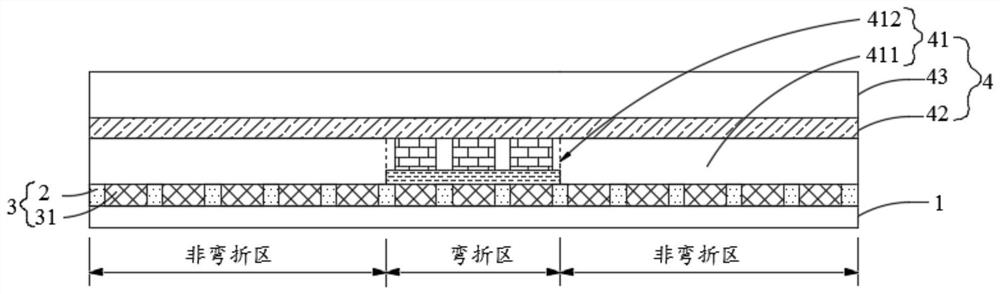

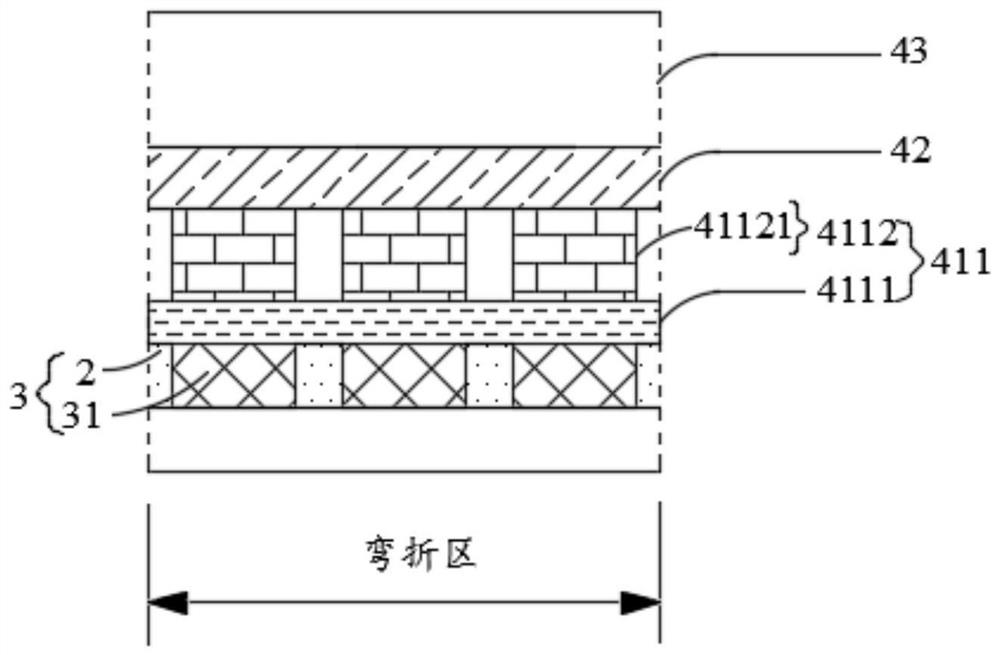

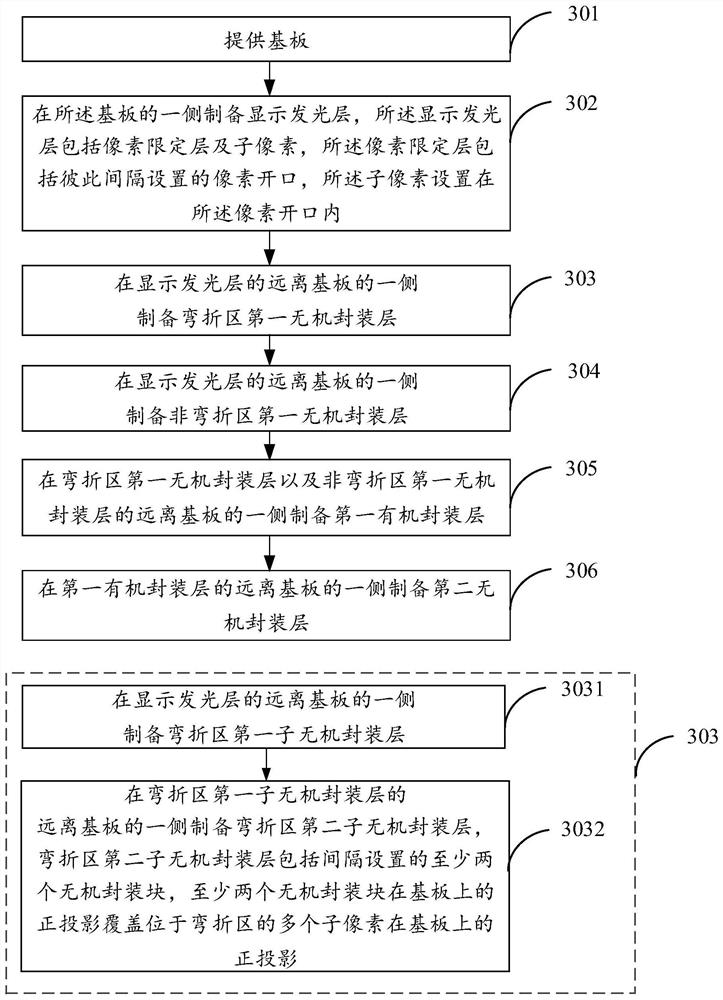

[0019] As mentioned in the background art, there are technical problems in the prior art that the thin film encapsulation layer of the flexible display panel is easily broken when bent or delaminated between layers, resulting in black spots on the screen and other display defects. The reason why such a problem arises is as follows. The existing thin film encapsulation layer adopts sequentially laminated organic encapsulation layer and inorganic encapsulation layer. Since the elastic modulus of the inorganic material itself is lower than that of the organic material, during the bending or folding process of the flexible display panel, the bending stress is mostly concentrated in the inorganic encapsulation layer. layer, the thicker the inorganic encapsulation layer, the greater the stress it suffers, and the easier it is to break or delaminate. However, if the inorganic encapsulation layer is too thin, it will affect the encapsulation effect, especially if the inorganic encapsu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com