Calcium sulfate bone cement containing bioglass and preparation method thereof

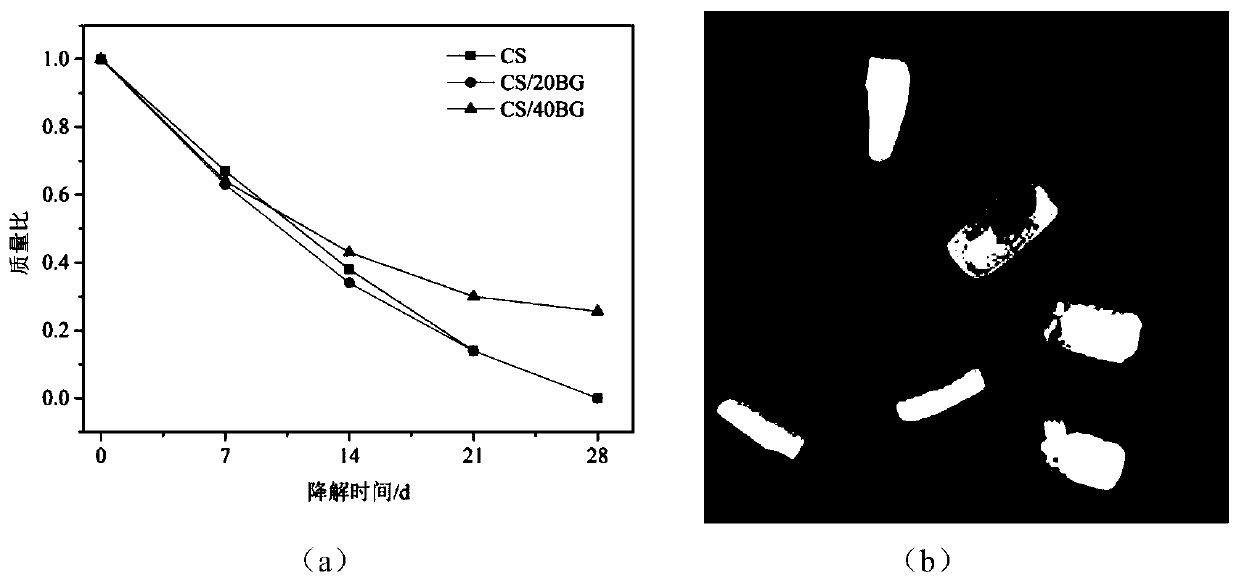

A technology of bioglass and calcium sulfate, which is applied in the field of biomedical materials, can solve the problems that bioglass cannot realize minimally invasive injection, cannot provide mechanical support, and the degradation time is too fast, and achieve excellent biocompatibility and osteogenic performance , excellent compressive strength, and the effect of delaying the degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A calcium sulfate bone cement (injection type) containing bioglass, prepared by the following method:

[0031] Prepare a sodium citrate and 2% magnesium sulfate solution with a mass concentration of 0.1%, add calcium sulfate dihydrate to the solution with a mass percentage of 20%, stir for 4 hours, filter, put it in a filter bag, and put it in a high-temperature and high-pressure device (Materials are not in contact with the water in the device), treated at 130°C for 6 hours, after treatment, put the materials in an environment of 110°C and dried for 3 hours, crushed, ground, and sieved the obtained materials to obtain α-calcium sulfate hemihydrate .

[0032] Mix 75 parts of α-calcium sulfate hemihydrate, 22 parts of bioglass, 2 parts of hypromellose, and 1 part of calcium chloride through mechanical grinding to make the powder evenly mixed, and then add water for injection according to the solid-to-liquid ratio of 1:0.4, Stir it into a slurry, then transfer it to a sy...

Embodiment 2

[0034] A calcium sulfate bone cement (injection type) containing bioglass, prepared by the following method: 55 parts of α-calcium sulfate hemihydrate prepared in Example 1, 5 parts of calcium sulfate dihydrate, 38 parts of bioglass, carboxymethyl 1.9 parts of sodium cellulose and 0.1 part of strontium chloride, the powder is mixed uniformly by mechanical grinding, then water for injection is added according to the solid-to-liquid ratio of 1:0.4, stirred into a slurry, then transferred to a syringe, and injected into normal saline , without collapsing for three days, the injection time is 11 minutes, injected into the mold, and then placed in a constant temperature and humidity box (temperature 37°C, humidity 98%) to cure and form. After curing for 3 days, the compressive strength is 11MPa.

Embodiment 3

[0036] A calcium sulfate bone cement (injection type) containing bioglass, prepared by the following method: 70 parts of α-calcium sulfate hemihydrate prepared in Example 1, 28 parts of bioglass, 1.5 parts of chitosan, 0.5 parts of magnesium sulfate Mix the powder evenly by mechanical grinding, then add physiological saline according to the solid-liquid ratio of 1:0.4, stir it into a slurry, then transfer it to a syringe, inject it into physiological saline, it will not collapse for three days, and the injectable time is 18 minutes , injected into the mold, and then placed in a constant temperature and humidity box (temperature 37°C, humidity 98%) for curing and molding. After curing for 3 days, the compressive strength is 16MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com