Carbon dioxide electrochemical reduction copper indium bimetallic co-doped organic framework catalyst and its preparation method and application

A carbon dioxide and electrochemical technology, applied in the field of co-doped bimetallic organic framework carbon dioxide electrochemical reduction catalyst and its preparation, can solve the problems of poor catalytic activity and selectivity, low energy efficiency, low current density, etc., and achieve simple preparation method , low cost, reduce the effect of catalyst deactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

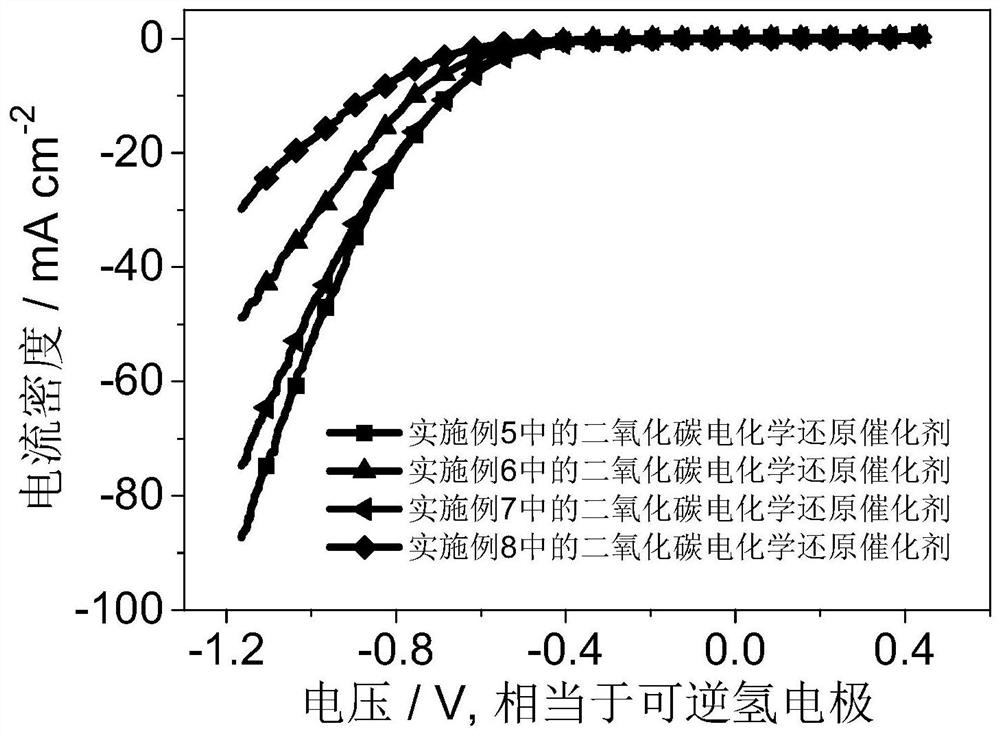

Image

Examples

Embodiment 1

[0027] This embodiment provides a preparation method of a carbon dioxide electrochemical reduction catalyst, the specific steps are as follows:

[0028] Step 1: 0.453g copper nitrate trihydrate and 0.188g InN 3 o 9 Dissolve in 50mL methanol solution at the same time to make a mixed solution of 0.0019M copper nitrate and 0.0006M indium nitrate, add 0.2053g 1,2-dimethylimidazole and 0.5253g 1,3,5-trimesic acid at the same time, stir for 30min and mix After uniformity, transfer to a 100mL reactor, put the reactor into an oven at 160°C for hydrothermal reaction for 12 hours, cool naturally, centrifuge, wash with methanol, and dry to obtain a precursor; the reactor is a polytetrafluoroethylene Hydrothermal reaction kettle with vinyl liner and stainless steel jacket;

[0029] Step 2: Put the precursor prepared in step 1 in a tube furnace, and calcine it with nitrogen gas for 1 hour. The calcination temperature is 350° C., and the calcination time is 4 hours. The black powder is ob...

Embodiment 2

[0031] This embodiment provides a preparation method of a carbon dioxide electrochemical reduction catalyst, the specific steps are as follows:

[0032] Step 1: 0.4010g copper nitrate trihydrate and 0.2497g InN 3 o 9 Dissolve in 50mL methanol solution at the same time, make a mixed solution of 0.0017M copper nitrate and 0.0008M indium nitrate, add 0.2053g 1,2-dimethylimidazole and 0.5253g 1,3,5-trimesic acid at the same time, stir for 30min and mix After uniformity, transfer to a 100mL reactor, put the reactor into an oven at 160°C for hydrothermal reaction for 12 hours, cool naturally, centrifuge, wash with methanol, and dry to obtain a precursor; the reactor is a polytetrafluoroethylene Hydrothermal reaction kettle with vinyl liner and stainless steel jacket;

[0033] Step 2: Put the precursor prepared in step 1 in a tube furnace, and calcine it with nitrogen gas for 1 hour. The calcination temperature is 350° C., and the calcination time is 4 hours. The black powder is ob...

Embodiment 3

[0035] This embodiment provides a preparation method of a carbon dioxide electrochemical reduction catalyst, the specific steps are as follows:

[0036] Step 1: Mix 0.302g copper nitrate trihydrate and 0.3760g InN 3 o 9 Dissolve in 50mL methanol solution at the same time to make a mixed solution of 0.0013M copper nitrate and 0.0013M indium nitrate, add 0.2053g 1,2-dimethylimidazole and 0.5253g 1,3,5-trimesic acid at the same time, stir for 30min and mix After uniformity, transfer to a 100mL reactor, put the reactor into an oven at 160°C for hydrothermal reaction for 12 hours, cool naturally, centrifuge, wash with methanol, and dry to obtain a precursor; the reactor is a polytetrafluoroethylene Hydrothermal reaction kettle with vinyl liner and stainless steel jacket;

[0037] Step 2: Put the precursor prepared in step 1 in a tube furnace, and calcine it with nitrogen gas for 1 hour. The calcination temperature is 350° C., and the calcination time is 4 hours. The black powder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com