A photosensitive catalytic energy-saving alloy material

A technology of alloy materials and energy-saving materials, which is applied in the field of photosensitive catalytic energy-saving alloy materials, can solve the problems of difficult control of the amount of precious metals used, low utilization rate of solar energy, easy agglomeration and loss, etc., achieve long service life, improve high-temperature mechanical properties, The effect of improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

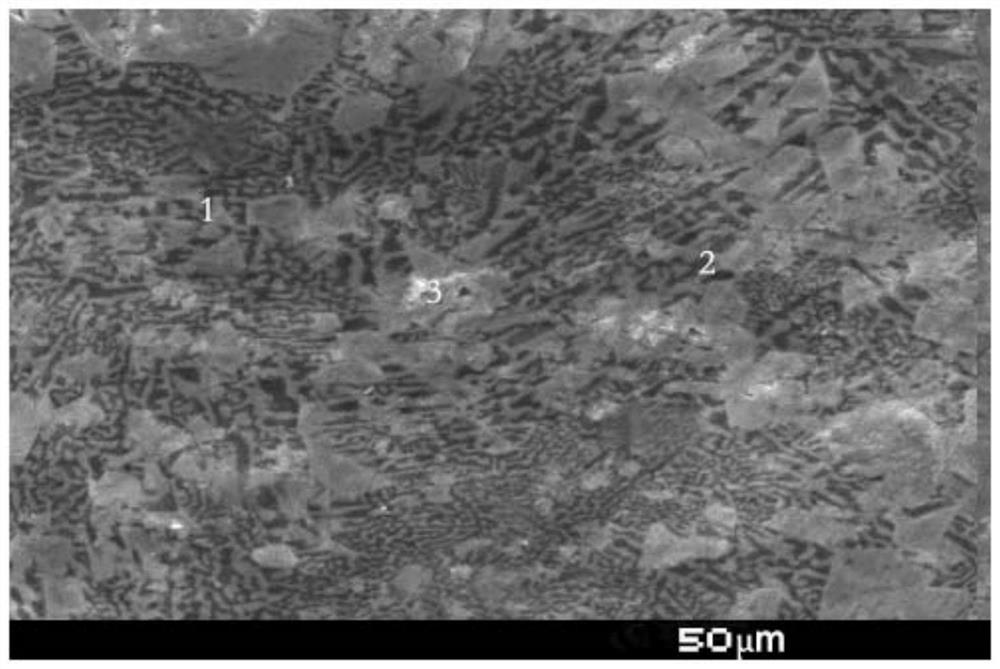

Image

Examples

Embodiment 1

[0022] 1. Configuration of raw materials:

[0023] Prepare the following ingots by weight percentage, Fe0.06wt.%, TI 0.5wt.%, AL: 6wt.%, Zr1wt.%, and the balance is Mg.

[0024] Cu, Pt, Ag are 1:0.5:0.7 by weight, the volume ratio of the mixed powder and the mixed solution of zinc stearate and acetone is 10±0.5%, and the weight ratio of zinc stearate to acetone is 1:4 .

[0025] 2. Prepared by the following method:

[0026] S1. Mix TI, AL, Mg, and Zr in the protective gas according to the calculated ratio, press in a cold state at a pressure of 80 MPa, and then heat up to 220°C, and perform secondary pressing in an atmospheric environment. The pressure is 50 MPa;

[0027] S2. Melt the above pressed alloy at 850°C, keep it warm for half an hour after it is completely melted, add the calculated Fe, keep at 850°C, add refining agent to remove slag and refine, smelt for 3 hours, stir once every 10 minutes, and cool down to 500°C;

[0028] S3. Put the casting melt in a shaping...

Embodiment 2

[0033] 1. Configuration of raw materials:

[0034] Prepare the following ingots by weight percentage, Fe1wt.%, TI 0.5wt.%, AL: 8wt.%, Zr2wt.%, and the balance is Mg.

[0035] Cu, Pt, Ag are 1:0.6:0.8 by weight, the volume ratio of the mixed powder and the mixed solution with zinc stearate and acetone is 10±0.5%, and the weight ratio of zinc stearate to acetone is 1:4 .

[0036] 2. Prepared by the following method:

[0037] S1. Mix TI, AL, Mg, and Zr in the protective gas according to the calculated ratio, press in a cold state at a pressure of 80-80-120MPa, then raise the temperature to 220°C, and perform secondary pressing in an atmospheric environment. The pressure is 50MPa;

[0038] S2. Melt the above pressed alloy at 850°C, keep it warm for half an hour after it is completely melted, add the calculated Fe, keep at 850°C, add refining agent to remove slag and refine, smelt for 3 hours, stir once every 10 minutes, and cool down to 500°C;

[0039] S3. Put the casting mel...

Embodiment 3

[0044] 1. Configuration of raw materials:

[0045] Prepare the following ingots by weight percentage, Fe1wt.%, TI 1wt.%, AL: 7wt.%, Zr2wt.%, and the balance is Mg.

[0046] Cu, Pt, Ag are 1:0.5:0.8 by weight, the volume ratio of the mixed powder and the mixed solution with zinc stearate and acetone is 10±0.5%, and the weight ratio of zinc stearate to acetone is 1:4 .

[0047] 2. Prepared by the following method:

[0048] S1. Mix TI, AL, Mg, and Zr in the protective gas according to the calculated ratio, press in a cold state at a pressure of 80-80-120MPa, then heat up to 220°C, and perform a second press in an atmospheric environment. The pressure is 50MPa;

[0049]S2. Melt the above pressed alloy at 850°C, keep it warm for half an hour after it is completely melted, add the calculated Fe, keep at 850°C, add refining agent to remove slag and refine, smelt for 3 hours, stir once every 10 minutes, and cool down to 500°C;

[0050] S3. Put the casting melt in a shaping mold f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com