Life Prediction Method of Conveyor Belt

A technology for life prediction and conveyor belts, used in testing wear resistance and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

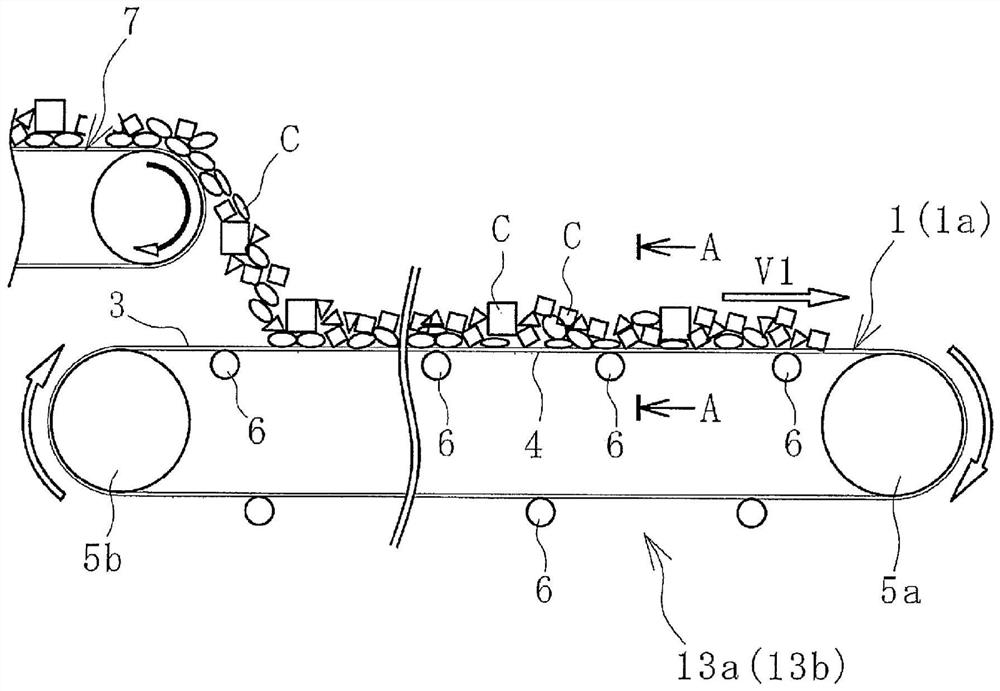

[0023] Hereinafter, the life prediction method of the conveyor belt of this invention is demonstrated based on embodiment shown in a figure.

[0024] exist figure 1 In the conveyor belt operation line exemplified in , the conveyed objects C conveyed by other conveyer belts 7 are put into the conveyer belt 1 and conveyed to the conveyance destination by the conveyer belt 1 . The conveyed object C may also be thrown into the conveyor belt 1 through a hopper or the like. The conveyor belt 1 is stretched between the pulleys 5a, 5b and tensioned at a predetermined tension.

[0025] Such as figure 2 As illustrated, the conveyor belt 1 is composed of a core layer 2 made of a core such as canvas and steel cord, and an upper cover rubber 3 and a lower cover rubber 4 sandwiching the core layer 2 . The core layer 2 is a member that receives tension for tension setting the conveyor belt 1 . On the carrier side of the conveyor belt 1 , the lower cover rubber 4 is supported by backup r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com