A kind of water-soluble formaldehyde-free wood adhesive and its preparation method and application

A wood adhesive, water-soluble technology, applied in the direction of adhesives, coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

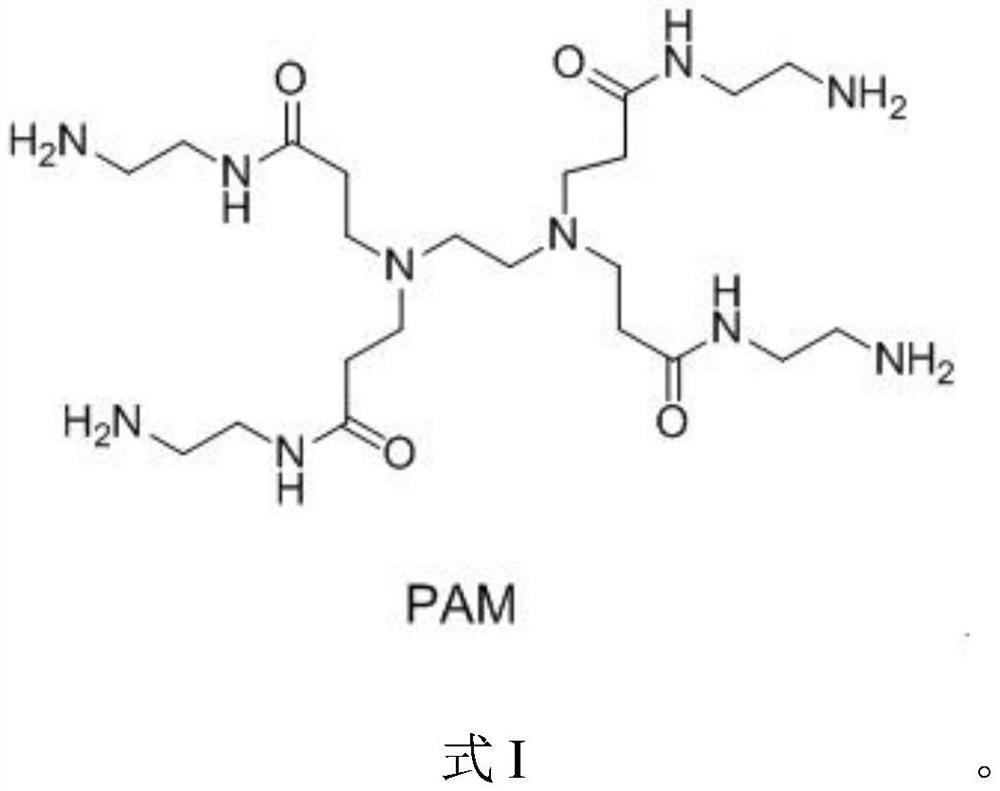

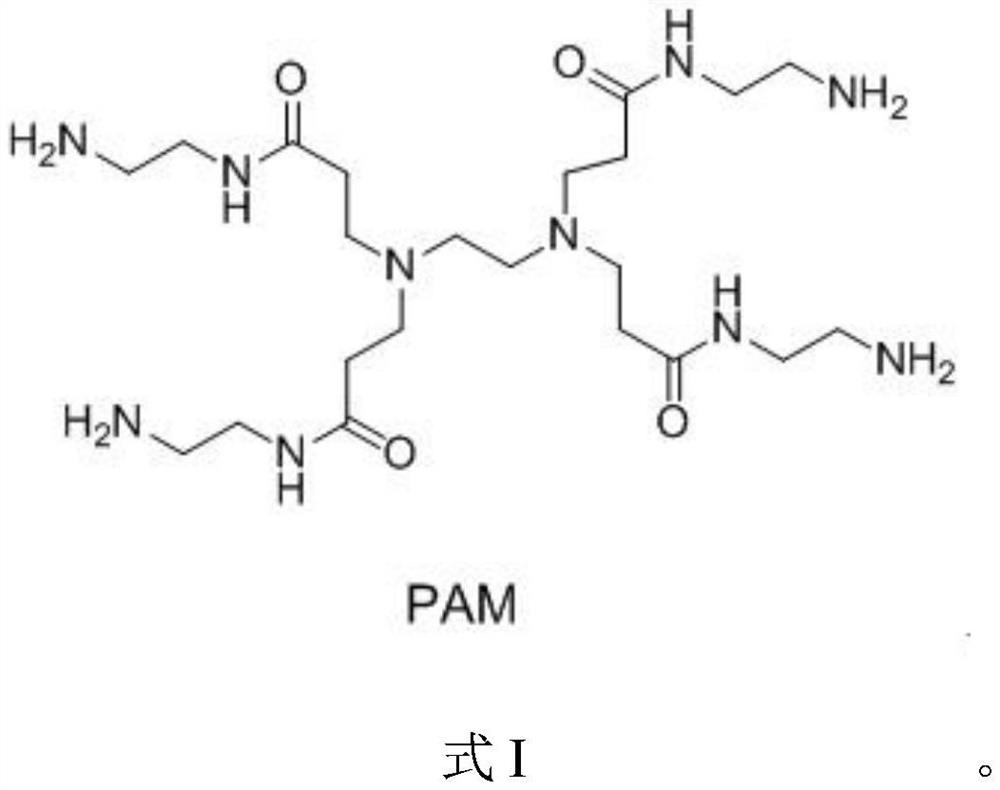

[0026] The preparation method of the water-soluble formaldehyde-free wood adhesive of the present invention comprises the following steps: the water-soluble formaldehyde-free wood adhesive generated by reacting branched polyamine and urea at 110-130° C. for 5.0-10.0 h, the urea and The molar ratio of the polyamino compound PAM is 2:1-8:1 to prepare a water-soluble formaldehyde-free wood adhesive.

[0027] The highly branched polymer resin adhesive produced by the reaction can be dissolved in the water phase, and the solid content after dissolution can be controlled at 40%-60%.

Embodiment 1

[0029] The preparation method of water-soluble formaldehyde-free wood adhesive of the present invention, comprises the steps: take polyamino compound PAM (28.5649g), add in the there-necked flask, add urea (6.64g) respectively again, the mol ratio of urea and PAM The ratio is 2:1, the reaction is mixed and stirred in an oil bath, reacted at 115°C for 10h, then cooled to room temperature, and added water to form a solution with a solid content of 40-60%.

Embodiment 2

[0031] The preparation method of water-soluble formaldehyde-free wood adhesive of the present invention, comprises the steps: take polyamino compound PAM (32.1314g), add in the there-necked flask, add urea (11.2g) respectively again, the mol ratio of urea and PAM The ratio is 3:1, the reaction is mixed and stirred in an oil bath, reacted at 115°C for 10h, then cooled to room temperature, and added water to form a solution with a solid content of 40-60%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com