Combined pneumatic conveying system for coal ash in coal-fired power plant and operating method thereof

A technology of pneumatic conveying system and coal-fired power station, which is applied in the direction of conveyors, conveying bulk materials, transportation and packaging, etc. It can solve problems such as pipeline blockage, achieve low system maintenance costs, reduce system shutdown frequency, and reduce fly ash The effect of the probability of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

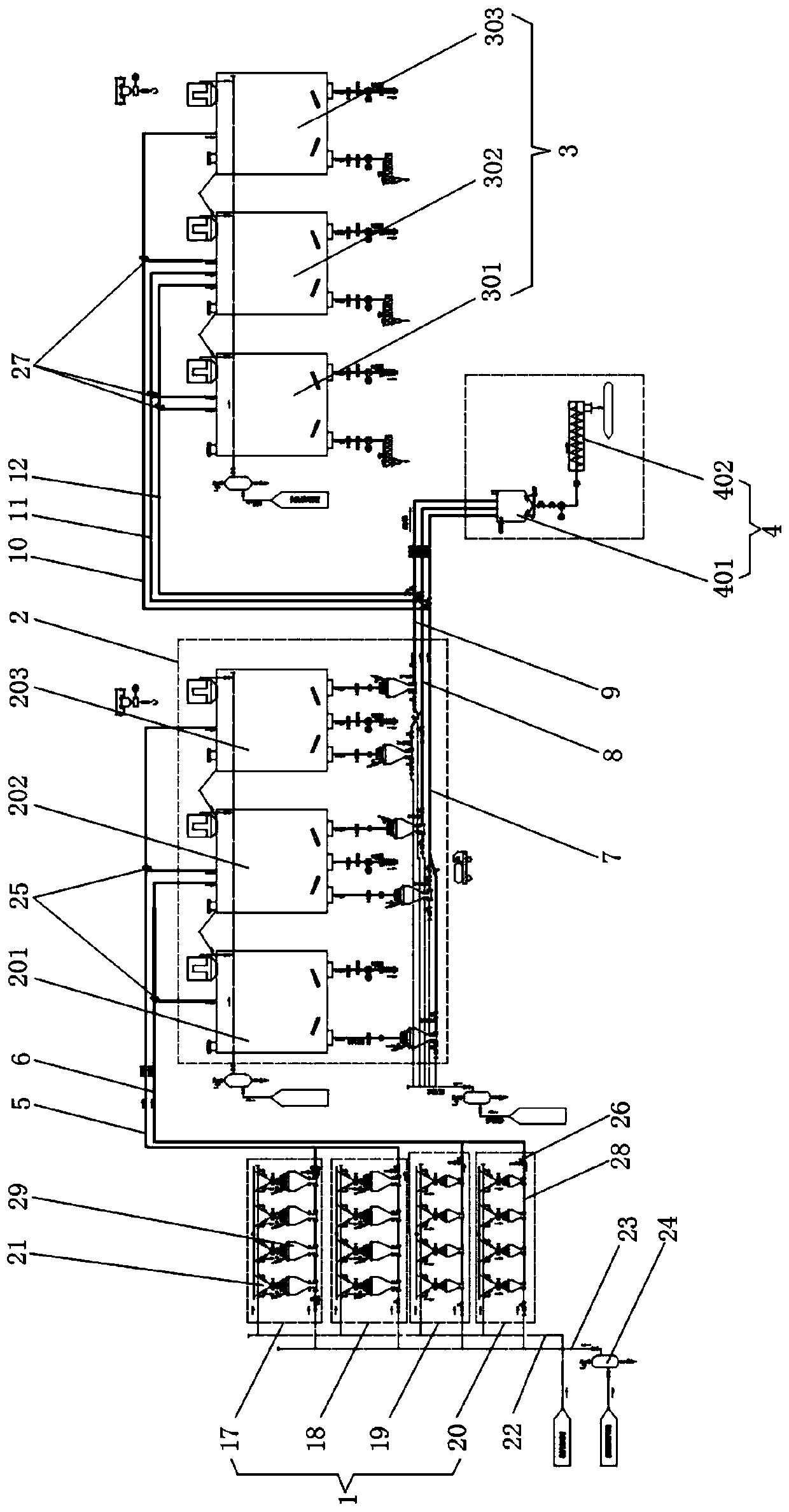

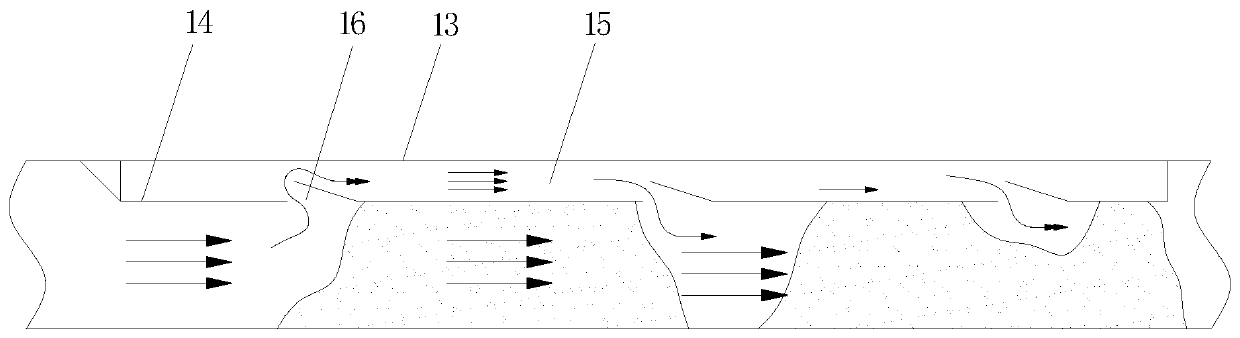

[0050] Embodiment 1 of the present invention: a coal-fired power station fly ash combined pneumatic conveying system, including a pneumatic dust collection and sending system 1, a transfer system 2, a terminal ash unloading system 3 and a fly ash loading system 4, and the pneumatic dust collection and sending system The system 1 is connected to the transit system 2 through the first conveying pipe 5 and the second conveying pipe 6, and the transit system 2 is connected to the fly ash shipping system 4 through the third conveying pipe 7, the fourth conveying pipe 8 and the fifth conveying pipe 9; It also includes a sixth conveying pipe 10, a seventh conveying pipe 11 and an eighth conveying pipe 12. One end of the sixth conveying pipe 10 is connected to the third conveying pipe 8, the other end is connected to the terminal ash unloading system 3, and the seventh conveying pipe One end of the pipe 11 is connected to the fourth conveying pipe 9, the other end is connected to the t...

Embodiment 2

[0051] Embodiment 2 of the present invention: a coal-fired power station fly ash combined pneumatic conveying system, including a pneumatic dust collection and sending system 1, a transfer system 2, a terminal ash unloading system 3 and a fly ash loading system 4, and a pneumatic dust collection and sending system 1 is connected to the transit system 2 through the first conveying pipe 5 and the second conveying pipe 6, and the transit system 2 is connected to the fly ash shipping system 4 through the third conveying pipe 7, the fourth conveying pipe 8 and the fifth conveying pipe 9; Including the sixth conveying pipe 10, the seventh conveying pipe 11 and the eighth conveying pipe 12, one end of the sixth conveying pipe 10 is connected with the third conveying pipe 8, and the other end is connected with the terminal ash unloading system 3, and the seventh conveying pipe One end of 11 is connected to the fourth conveying pipe 9, the other end is connected to the terminal ash unlo...

Embodiment 3

[0055] Embodiment 3 of the present invention: a coal-fired power station fly ash combined pneumatic conveying system, including a pneumatic dust collection and sending system 1, a transfer system 2, a terminal ash unloading system 3 and a fly ash loading system 4, and a pneumatic dust collection and sending system 1 is connected to the transit system 2 through the first conveying pipe 5 and the second conveying pipe 6, and the transit system 2 is connected to the fly ash shipping system 4 through the third conveying pipe 7, the fourth conveying pipe 8 and the fifth conveying pipe 9; Including the sixth conveying pipe 10, the seventh conveying pipe 11 and the eighth conveying pipe 12, one end of the sixth conveying pipe 10 is connected with the third conveying pipe 8, and the other end is connected with the terminal ash unloading system 3, and the seventh conveying pipe One end of 11 is connected to the fourth conveying pipe 9, the other end is connected to the terminal ash unlo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap