A hoisting structure for the production of glass raw sheets

A technology of original sheet and glass, applied in the field of glass original sheet production and hoisting structure, can solve the problems of low efficiency, large manpower investment, affecting glass production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

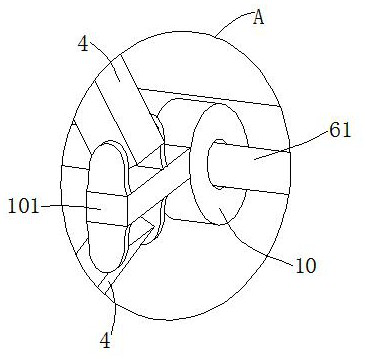

[0026] see Figure 1-3 , this embodiment provides a hoisting structure for the production of glass original sheets, including two support mechanisms 1, both of which include support beams 11 and support columns 13, and the middle sections of the top ends of the two support beams 11 are all vertical Welded with the first mounting column 8, the tops of the two first mounting columns 8 are welded with the second mounting column 6 vertically, the tops of the two second mounting columns 6 are welded with the third mounting column 5 vertically, and the two first mounting columns 6 are vertically welded with the third mounting column 5. A first guide rod 81 is fixedly inserted between the opposite side walls of the top of the mounting column 8, and a threaded adjustment rod 61 is rotationally inserted between the opposite side walls of the top of the two second mounting columns 6, and the outer wall of the threaded adjustment rod 61 passes through There are two threaded sleeves 10 di...

Embodiment 2

[0033] see Figure 1-3 , further improvements have been made on the basis of Example 1:

[0034] The top of the supporting columns 13 of the two supporting mechanisms 1 is fixedly welded with a reinforcing beam 14 between the opposite side walls, and each supporting column 13 is vertically welded on the rear side of the top surface of each supporting beam 11 respectively; the bottom end surface of each supporting beam 11 Universal wheels 12 are rotated on the front and rear sides, and the stability of the support of the two support mechanisms 1 can be enhanced by setting the reinforcing beam 14, and the overall structure can be moved easily by setting the universal wheels 12;

[0035] The right end of the threaded adjustment rod 61 rotates through the side wall of the second mounting column 6 on the right side, and extends to the right side of the second mounting column 6. The right end of the threaded adjusting rod 61 is fixedly welded with The rotating disc 2, and the right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com