Continuous thread supply type rotary shuttle device

A thread supply and hollow hook shaft technology, applied in textiles and papermaking, sewing equipment, sewing machine ring mechanism, etc., can solve the problems of waste of bottom thread materials, prone to failure, high input cost, etc., to reduce equipment input cost, The effect of improving production efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

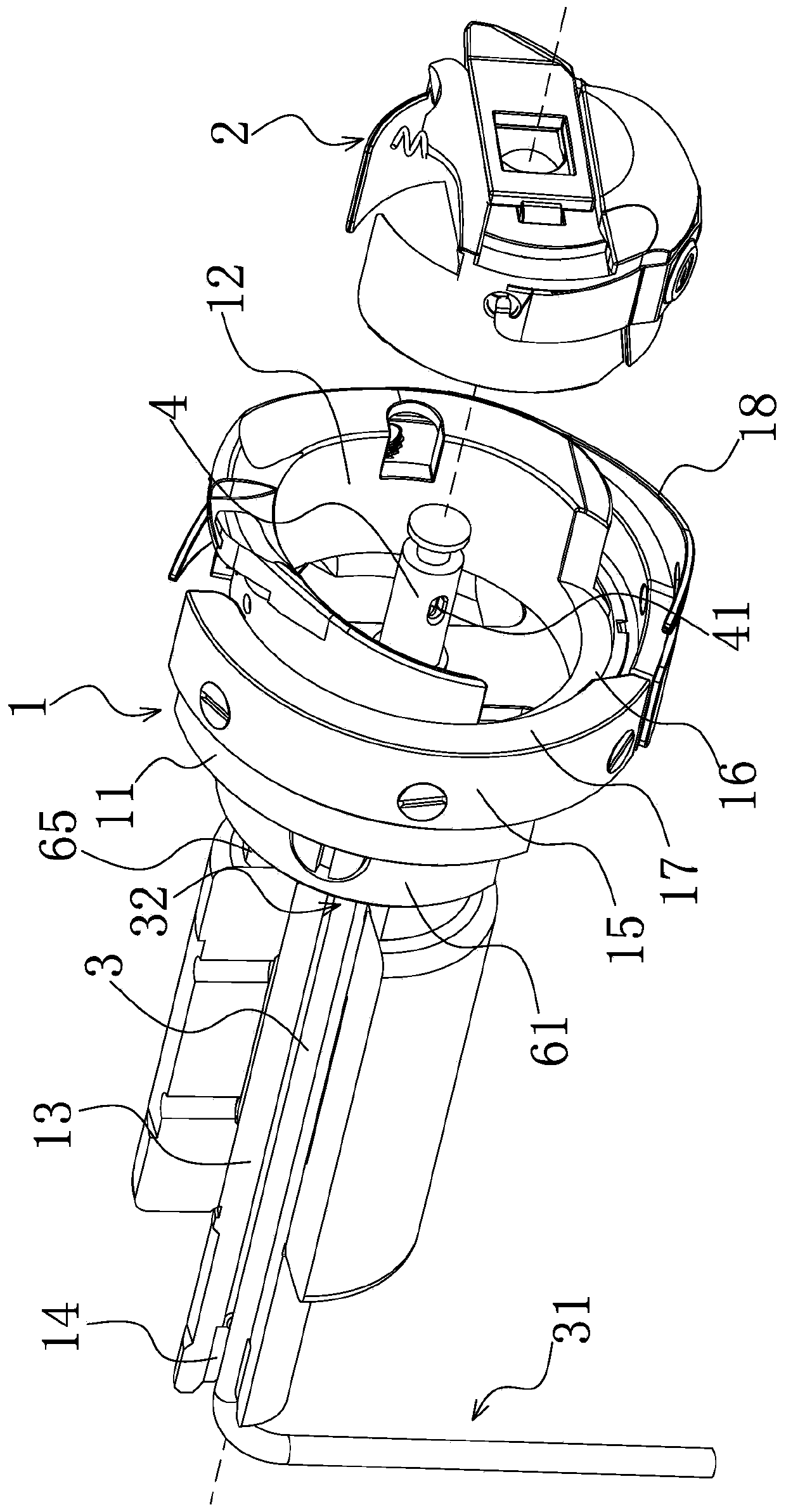

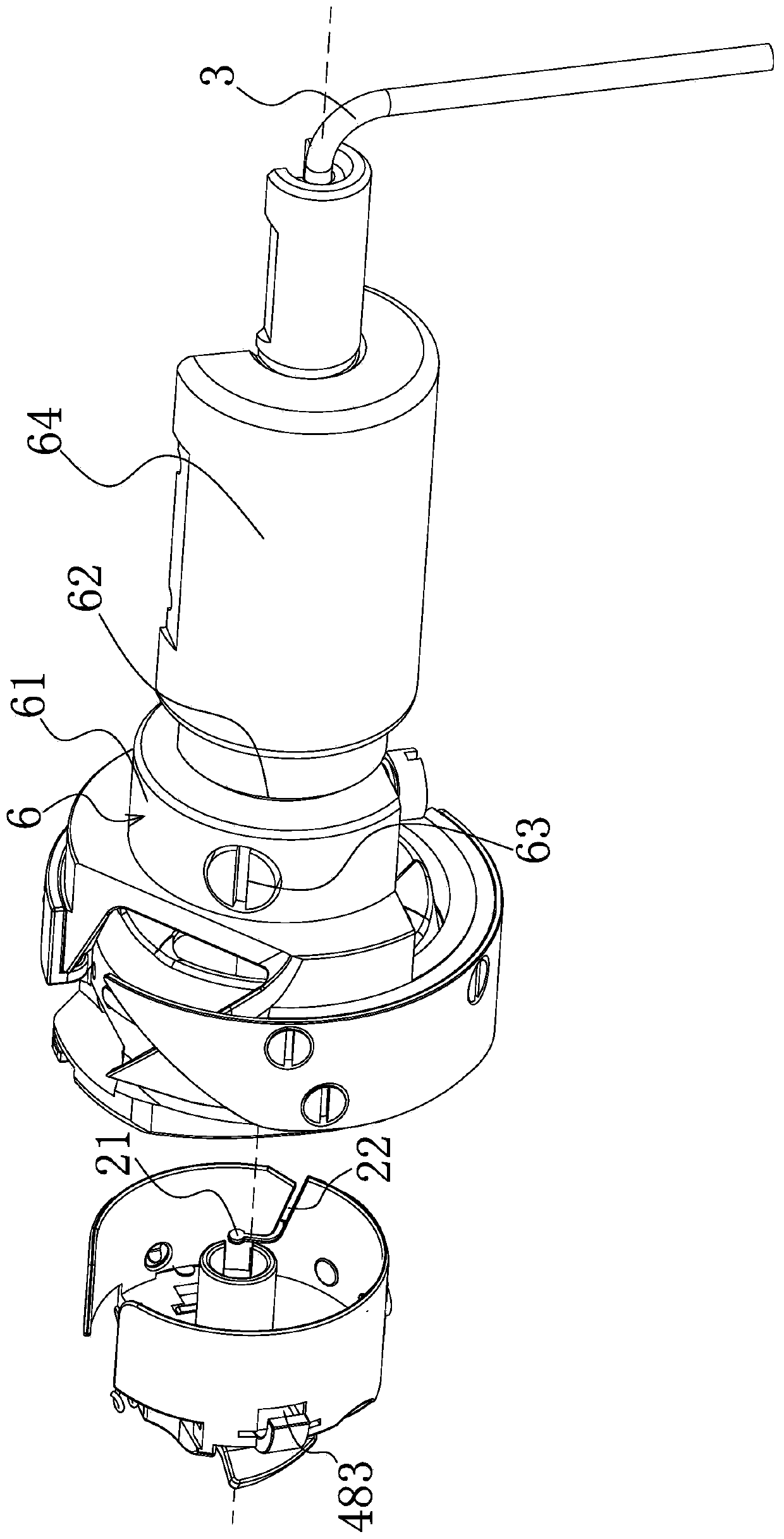

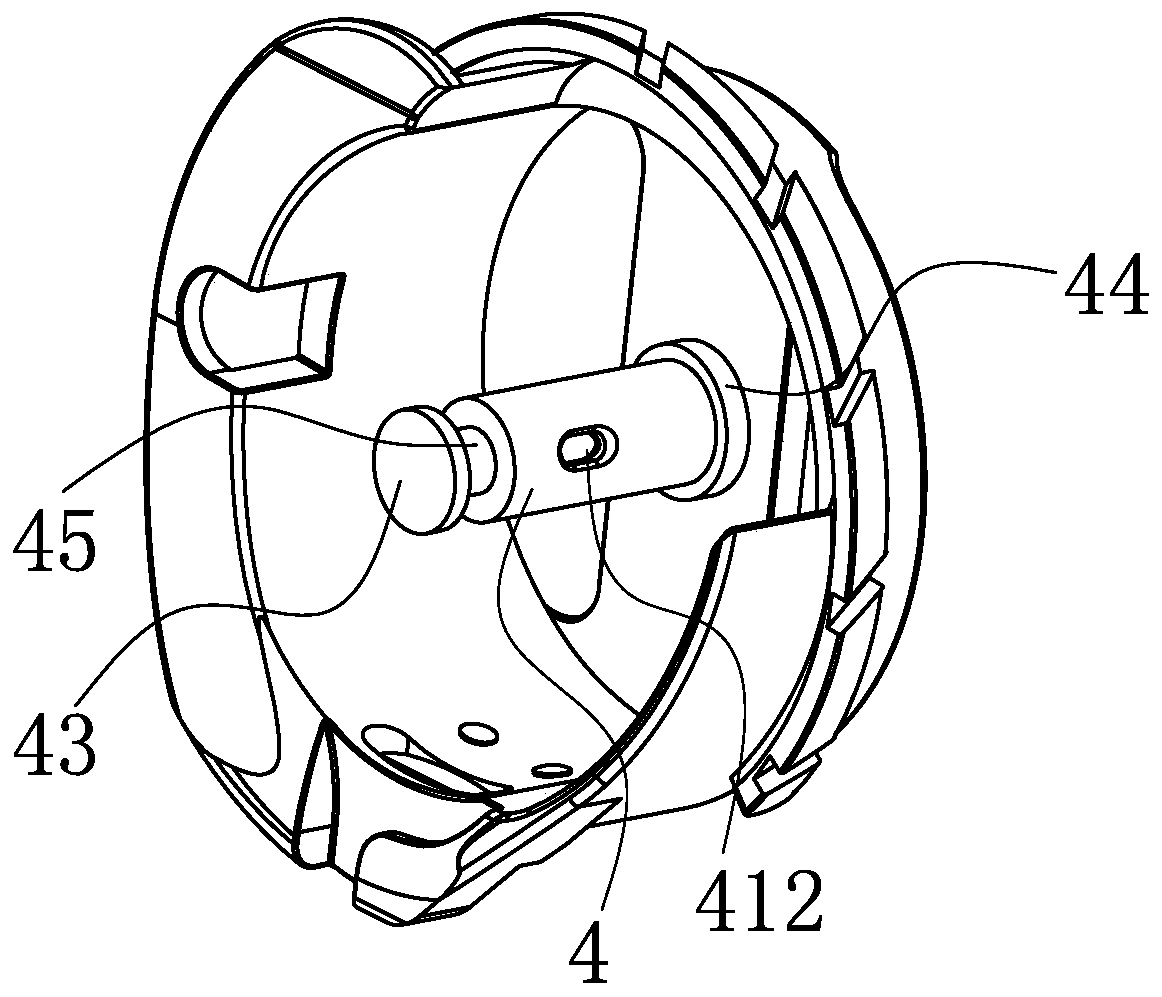

[0039] Such as Figure 1-8 As shown, the continuous thread supply rotary hook device includes a rotary hook body 1, one end of the rotary hook body 1 is equipped with a bobbin case body 2, and the end of the rotary hook body 1 away from the bobbin case body 2 is provided with a hollow wire. Tube 3, the inner side of the other end of the rotary hook body 1 close to the bobbin case body 2 has a shuttle frame mandrel 4, and the circumferential inner side of the shuttle frame mandrel 4 has a shuttle frame mandrel threading channel 41, and the wire tube 3 runs through the rotary hook body 1 and inserted into the threading channel 41 of the shuttle frame mandrel, the threading channel 41 of the shuttle frame mandrel communicates with the threading hole / groove 42 of the shuttle frame mandrel arranged on the outer side of the shuttle frame mandrel 4, and the bobbin case body 2 The inner side of one end corresponding to the rotary hook body 1 is provided with a hollow mandrel 5 that is...

Embodiment 2

[0050] Such as Figure 9-13 As shown, the structure, principle and steps of this embodiment are similar to those of Embodiment 1, the difference is that a circumferential positioning structure 7 is provided between the rotary hook body 1 and the bobbin case body 2 in this embodiment. The bobbin body 71, the bobbin body 71 has a cylindrical bobbin body 711, the outer side of the bobbin body 711 has an annular plate 712, the annular plate 712 can play a dustproof effect, and the other end is connected to the outer side There is an anti-rotation body 713, and the bobbin barrel 711 has an axially extending passageway 714 that runs through the annular plate 712 and the anti-rotation body 713 respectively. 5 is inserted from the other end of the thread passing channel 714, the shuttle frame mandrel 4 and the hollow mandrel 5 are inserted into each other in the thread passing channel 714 and the shuttle frame mandrel 4 passes through the hollow mandrel 5 and is positioned by the shut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com