Three-antipode six-layer flat copper wire winding structure and motor using winding structure

A technology of winding structure and flat copper wire, which is applied in the field of motor winding structure and the motor applying the winding structure, which can solve the problem of the small number of series turns of each phase winding of the motor, the inability to simplify the way of lead-out wires, and the limited use of winding forms, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

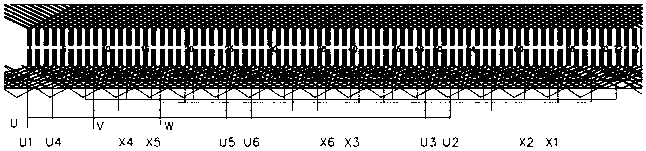

[0025] Such as figure 1 As shown, a winding structure of 72 slots, 3 pairs of poles, 6 layers of flat copper wires and 6 branches, which includes a three-phase winding structure distributed in at least six winding layers, and each phase winding structure includes a 6-phase winding structure composed of a plurality of winding units. winding branch. The six winding branches are evenly distributed on the circumference, and the winding units on each winding branch are distributed in one pair of poles.

[0026] In this embodiment, each winding branch includes a U-shaped lead-out terminal and a welding terminal. The pitches of the welded ends of each winding branch are equal, which is convenient for automatic wire insertion. The lead-out terminal of the U-shaped cable contains 3 pitch types, which are 11, 12 and 14 respectively. The lead-out terminals of each winding branch are arranged on the outermost winding layer, which is convenient for connecting each winding branch by mean...

Embodiment 2

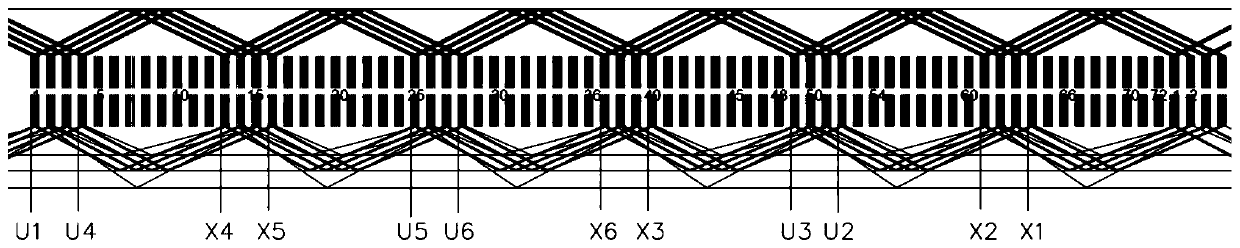

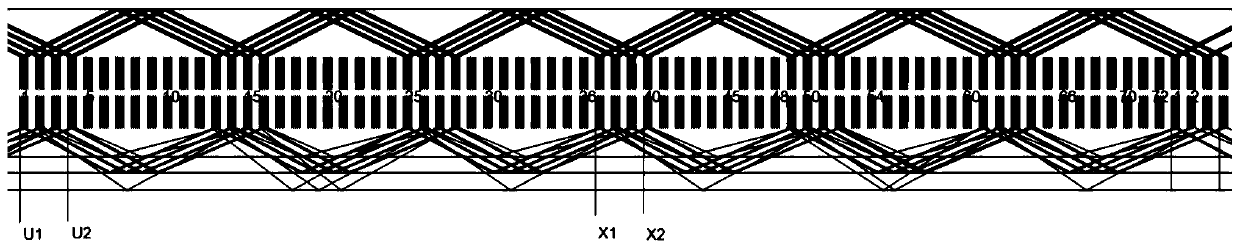

[0032] Such as image 3 As shown, it is a schematic connection diagram of the winding structure of this embodiment, taking the U-phase stacked winding as an example (the V and W phases are similar to the U phase, and will not be described in detail here), it is a deformation on the structure of the embodiment 1, That is, X1 is connected to U2, and X2 is connected to U3 to form a branch; X4 is connected to U5, and X5 is connected to U6 to form another branch.

[0033] U-phase 1st branch winding from image 3 It goes in at the position of U1, and outputs from the position of X1 to the center point of the three phases. U phase second branch winding from image 3 The U2 in the circuit goes in at the position, and outputs from the position of X2 to the three-phase central point.

[0034] A motor for a new energy vehicle, comprising the above-mentioned 3-pair pole 6-layer flat copper wire winding structure of the present invention, the motor has a high power density and a small v...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap