A synthetic method of tellurium nanorods based on genetically engineered polypeptides

A technology of tellurium nanorods and synthesis methods, applied in the field of synthesis of tellurium nanorods based on genetically engineered polypeptides, can solve the problems of difficult removal of chemical molecules, uneven shape, high toxicity, etc., and achieve low cost, low toxicity, and mild reaction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Tellurium nanorods polypeptide synthesis methods based on genetic engineering, comprising the steps of: 8ml of sodium tellurite solution (5 mM) and 1ml PC in 10ml round-bottomed flask 10 A protein solution (1mg / ml, with NaOH solution adjusted to pH 8), after vigorous stirring thoroughly mixed, then added rapidly a solution of sodium borohydride new configuration (10OmM) at 1ml, 30 ℃, rapid reaction was stirred 2h, dialysis (dialysis bag molecular weight 3500 Da) obtained after 6h tellurium nanorods.

Embodiment 2

[0028] Add 1ml of sodium tellurite in 10ml round bottom flask (2mM) and 1mg PC 10 Protein A (with NaOH solution adjusted to pH 8), mixed with vigorous stirring, then added rapidly to the new configuration sodium borohydride solution (10OmM) at 200μl, 30 ℃, rapid reaction was stirred 4h, dialysis (dialysis bag molecular weight after 3500Da) 6h tellurium nanorods obtained.

Embodiment 3

[0030] Add 1ml of sodium tellurite in 10ml round bottom flask (2mM) and 1mg PC 10 Protein A (with NaOH solution adjusted to pH 8), mixed with vigorous stirring, then added rapidly to the new configuration sodium borohydride solution (10OmM) at 200μl, 30 ℃, rapid reaction was stirred 4h, dialysis (dialysis bag molecular weight after 3500Da) 6h tellurium nanorods obtained.

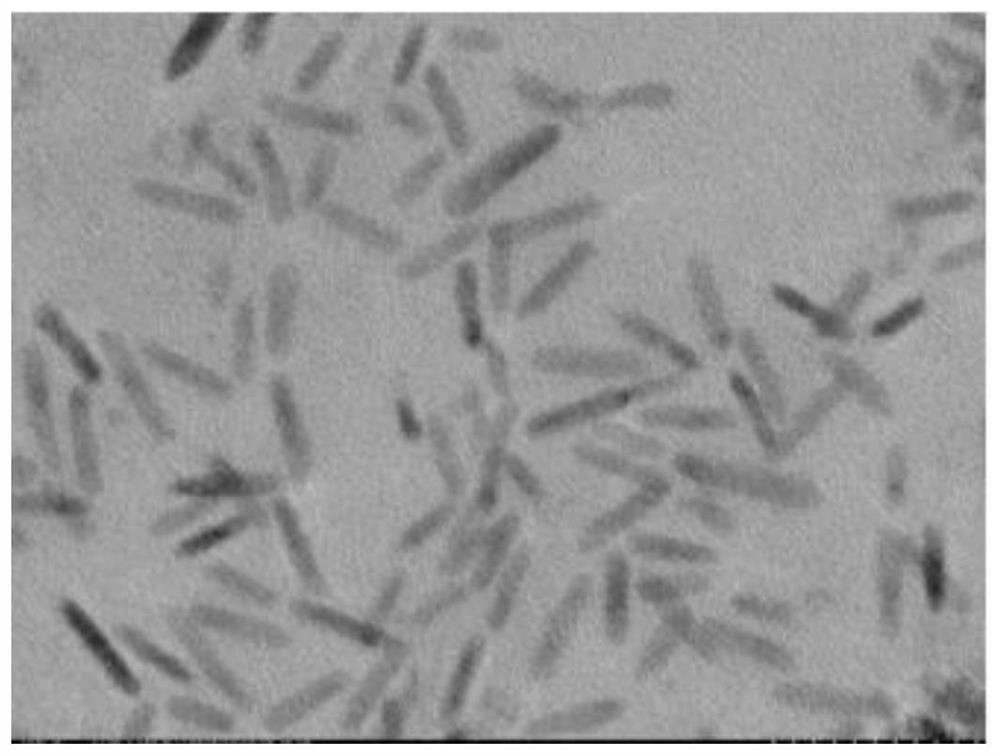

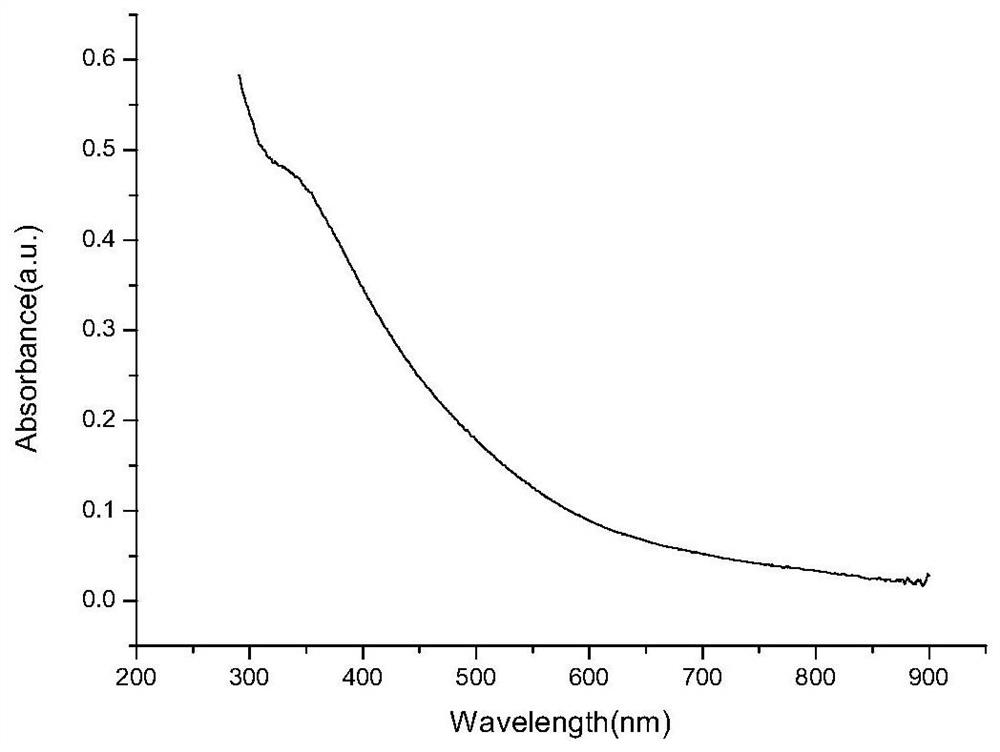

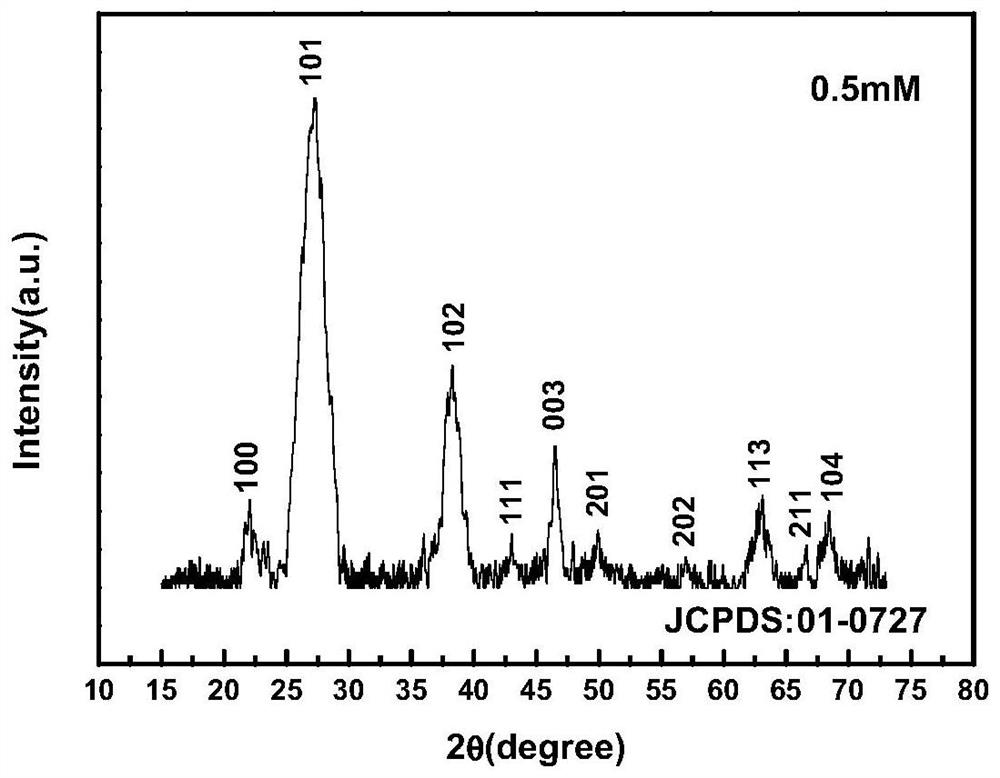

[0031] Take 20μl present application prepared tellurium nanorods dropwise copper mesh obtained using transmission electron microscopy tellurium nanorods were characterized by transmission electron microscopy spectrum (TEM) see figure 1 , It found: tellurium nanorods prepared diameter of 4 ~ 6nm, a length of 20 ~ 30nm, good dispersibility. Take 200μl detection UV-vis spectroscopy, figure 2 Showed consistent absorption auxiliary agent and conventional chemical synthesis tellurium rod. image 3 X-ray diffraction pattern, the purified solution was lyophilized to a powder by 09empyrean x- ray diffractometer analysis, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com