Pipeline reaction synthesis method of p-nitroaniline

A p-nitroaniline, pipeline reaction technology, applied in the direction of nitro compound preparation, amino compound preparation, chemical instruments and methods, etc., can solve the irritating taste of p-nitroaniline, high pressure of nitroaniline, and lack of high yield Quality and other issues, to achieve the effect of no explosion risk, sufficient response, and increased utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

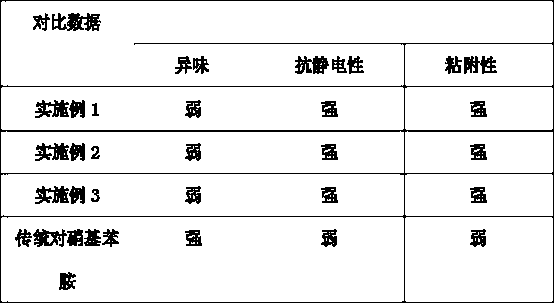

Examples

Embodiment 1

[0023] A kind of synthesis method of p-nitroaniline pipeline reaction, comprises the following steps:

[0024] Step 1: First, carry out nitration reaction of chlorinated benzene and mixed acid to obtain: 63% p-nitrochlorinated benzene, 35% o-nitrochlorinated benzene, 1% p-nitrochlorinated benzene, and dinitrochlorinated benzene 1% mixture;

[0025] Step 2: Put the above mixture into a pulverizer, grind it into a powdered p-nitrochlorobenzene with a particle size of 1000 mesh, put it into the reactor, install a vibration motor at the bottom of the reactor, and vibrate the reactor, while Continuously add cold air into the reaction kettle through the external pipeline of the compressor, control the temperature in the reaction kettle at 5°C, and the pressure at 1MPa for 5 minutes;

[0026] Step 3: Add ammonia water with a concentration of 39% to the powder that has been fully cooled in step 2, and quickly add it to the pipeline reactor with a feed pump, keeping the pressure at 6M...

Embodiment 2

[0035] A kind of synthesis method of p-nitroaniline pipeline reaction, comprises the following steps:

[0036] Step 1: First, carry out nitration reaction of chlorinated benzene and mixed acid to obtain: 63% p-nitrochlorinated benzene, 35% o-nitrochlorinated benzene, 1% p-nitrochlorinated benzene, and dinitrochlorinated benzene 1% mixture;

[0037] Step 2: Put the above mixture into a pulverizer, grind it into a powdered p-nitrochlorobenzene with a particle size of 1000 mesh, put it into the reactor, install a vibration motor at the bottom of the reactor, and vibrate the reactor, while Continuously add cold air into the reactor through the external pipeline of the compressor, control the temperature in the reactor at 10°C, and the pressure at 1MPa for 10 minutes;

[0038] Step 3: Add ammonia water with a concentration of 41% to the powder that has been fully cooled in step 2, and quickly add it to the pipeline reactor with a feed pump, keeping the pressure at 6.9MPa and the t...

Embodiment 3

[0047]A kind of synthesis method of p-nitroaniline pipeline reaction, comprises the following steps:

[0048] Step 1: First, carry out nitration reaction of chlorinated benzene and mixed acid to obtain: 63% p-nitrochlorinated benzene, 35% o-nitrochlorinated benzene, 1% p-nitrochlorinated benzene, and dinitrochlorinated benzene 1% mixture;

[0049] Step 2: Put the above mixture into a pulverizer, grind it into a powdered p-nitrochlorobenzene with a particle size of 1000 mesh, put it into the reactor, install a vibration motor at the bottom of the reactor, and vibrate the reactor, while Continuously add cold air into the reactor through the external pipeline of the compressor, control the temperature in the reactor at 10°C, and the pressure at 1MPa for 10 minutes;

[0050] Step 3: Add ammonia water with a concentration of 41% to the powder that has been fully cooled in step 2, and quickly add it to the pipeline reactor with a feed pump, keeping the pressure at 6.9MPa and the te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com