Hard and brittle material laser assisted machining hard and brittle material method of laser modified ultra-precision cutting

A laser-assisted, hard and brittle material technology, applied in the field of laser-assisted processing of hard and brittle materials, laser-modified ultra-precision cutting laser-assisted processing of hard and brittle materials, can solve the problem that the geometric position relationship between the tool and the laser focus cannot be kept constant, etc. Achieve the effect of focusing conveniently, improving the absorption rate, and fulfilling the basic requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

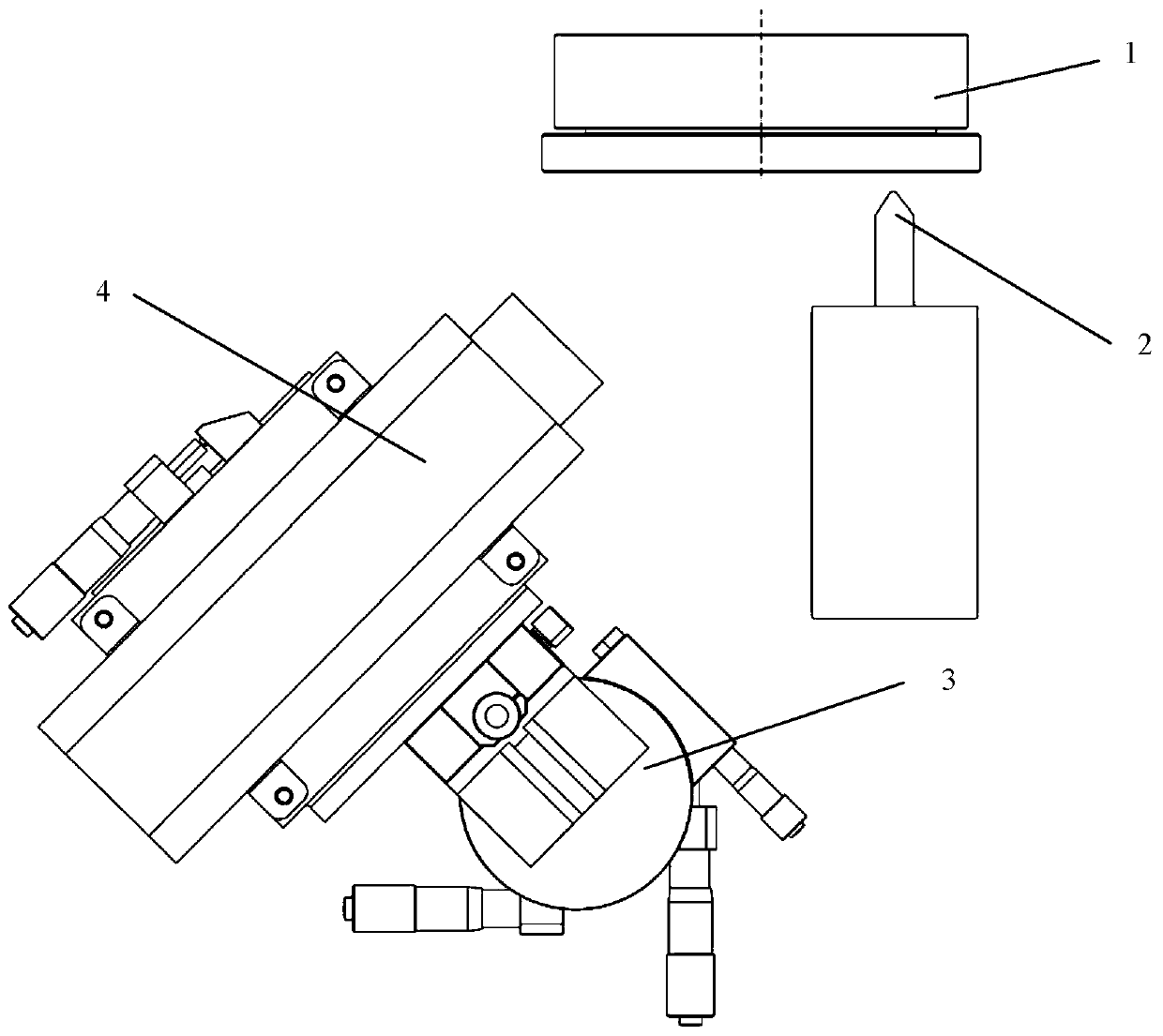

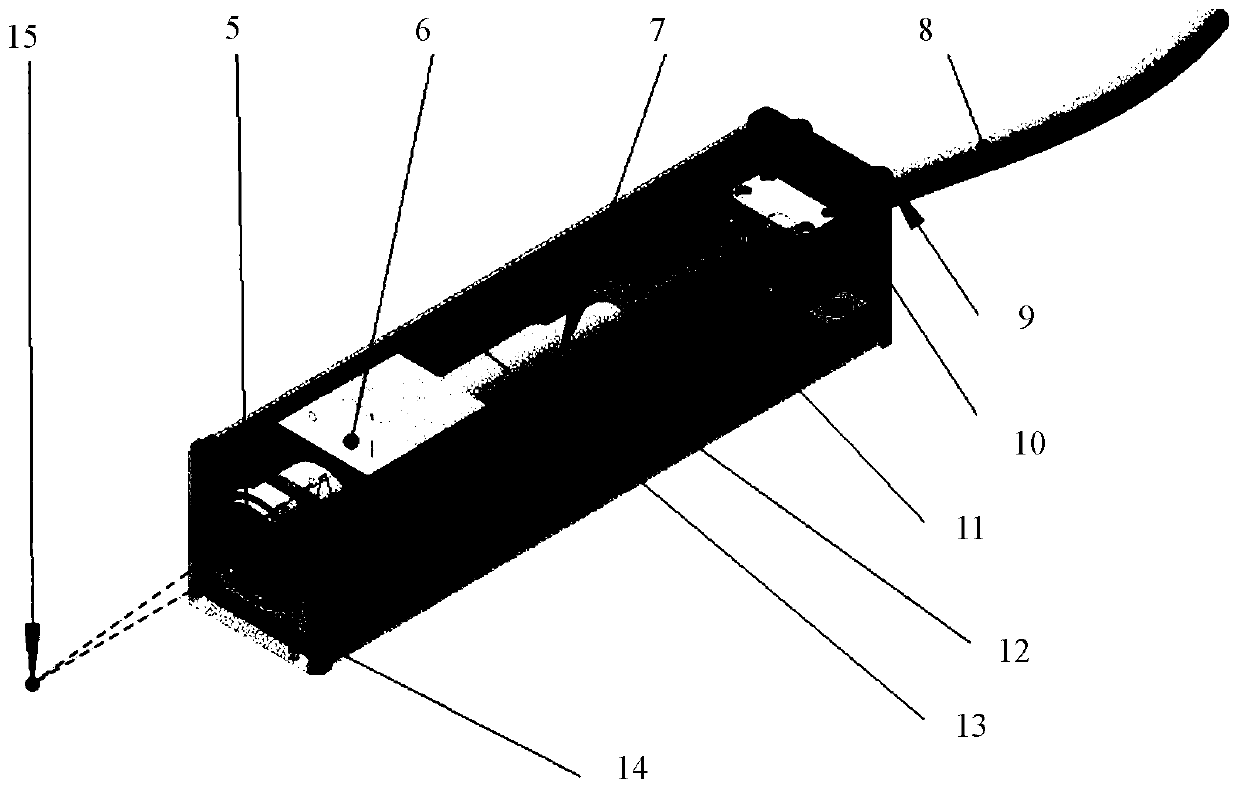

[0047] Specific implementation mode one: combine Figure 1 to Figure 6 To illustrate this embodiment, the specific steps of a method for laser-assisted processing of hard and brittle materials by laser modified ultra-precision cutting described in this embodiment are as follows:

[0048] Step 1. Build a laser-assisted cutting platform;

[0049] Step 2. Focus the continuous laser beam generated by the laser output head on the surface of the workpiece;

[0050] Step 3, using the tool 2 to cut the modified workpiece surface.

specific Embodiment approach 2

[0051] Specific implementation mode two: combination Figure 1 to Figure 6 Describe this embodiment, the laser-assisted cutting platform in step 1 of the laser-assisted processing hard and brittle material method described in this embodiment includes a five-axis manual displacement platform 3 and a laser processing module 4, the laser processing module 4 installed on the five-axis manual displacement platform 3;

[0052] The steps to build a laser-assisted cutting platform are:

[0053] Step A, installing the laser processing module 4 on the five-axis displacement platform 3;

[0054] Step B, installing the five-axis displacement platform 3 on the ultra-precision machine tool 1;

[0055] Step C, installing the tool 2 on the ultra-precision machine tool 1 .

specific Embodiment approach 3

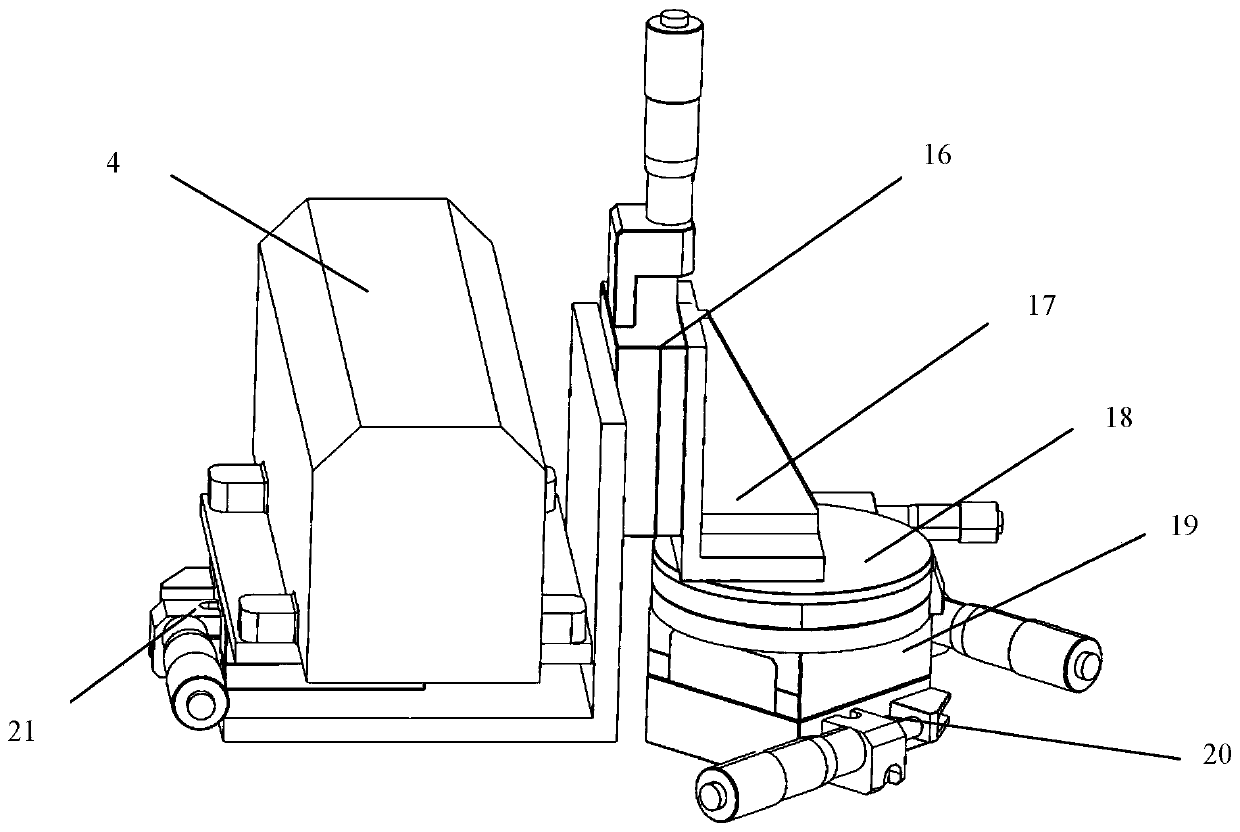

[0056] Specific implementation mode three: combination Figure 1 to Figure 6 Describe this embodiment, the five-axis manual displacement platform 3 of the laser-assisted processing hard and brittle material method described in this embodiment includes a vertical Y direction manual displacement platform 16, a connecting rib 17, a rotating R Direction manual displacement platform 18, linear Z direction manual displacement platform 19, linear X direction manual displacement platform 20 and linear W direction manual displacement platform 21; laser processing module 4 is installed on the linear W direction manual displacement platform 21, linear W direction manual displacement platform The platform 21 is installed on the manual displacement platform 16 in the vertical Y direction. The manual displacement platform 16 in the vertical Y direction is connected with the manual displacement platform 18 in the R direction through the connecting rib 17. The manual displacement platform 18 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com