Alloy smelting furnace slag removing device and use method thereof

A smelting furnace and slag technology, applied in the application field of alloy smelting furnaces, can solve the problems of unguaranteed safety performance, low work efficiency, easy generation of dust, etc., and achieve the effects of improved efficiency, thorough cleaning, and increased cleaning area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be clearly and completely described below in conjunction with the embodiments. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

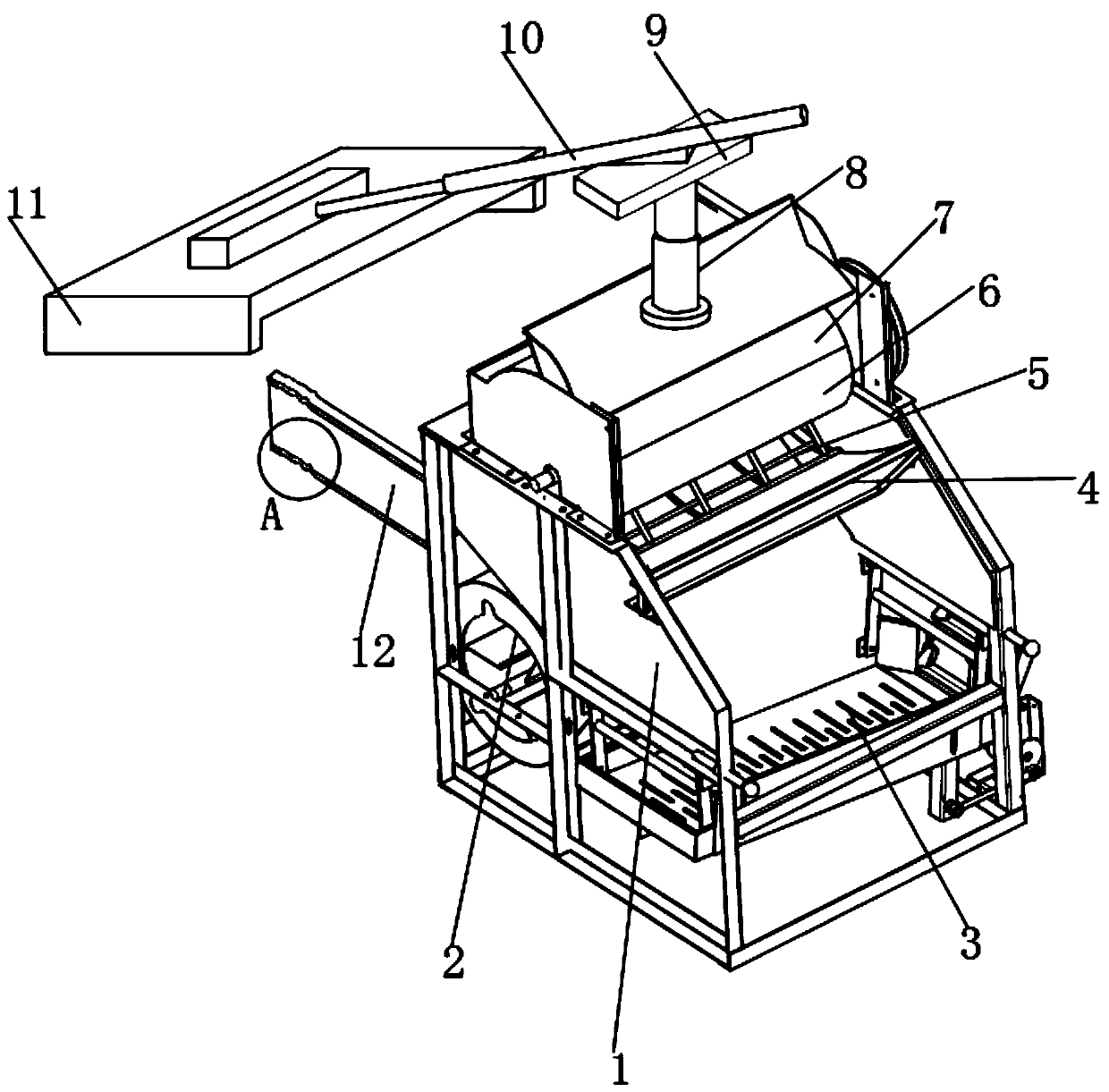

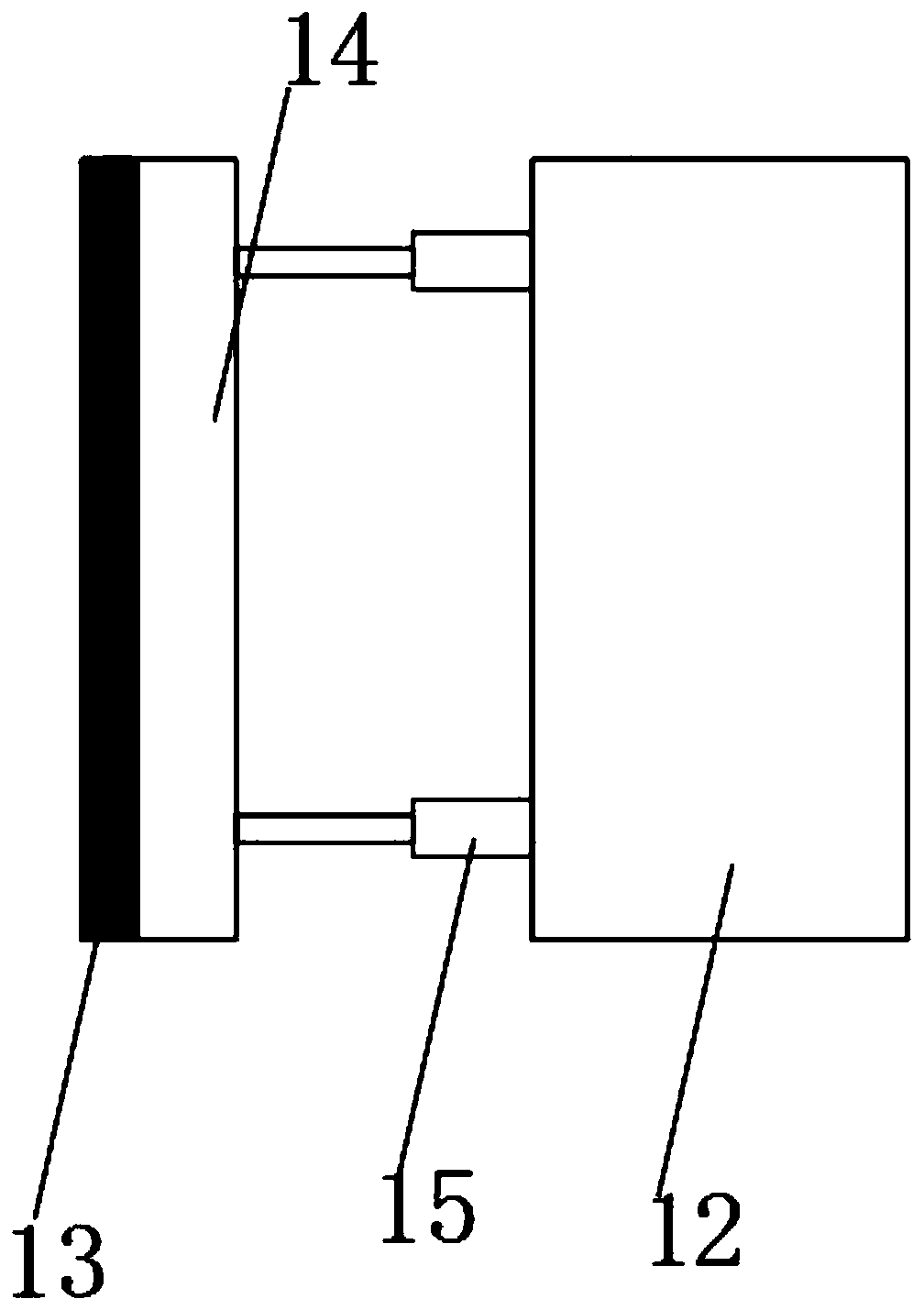

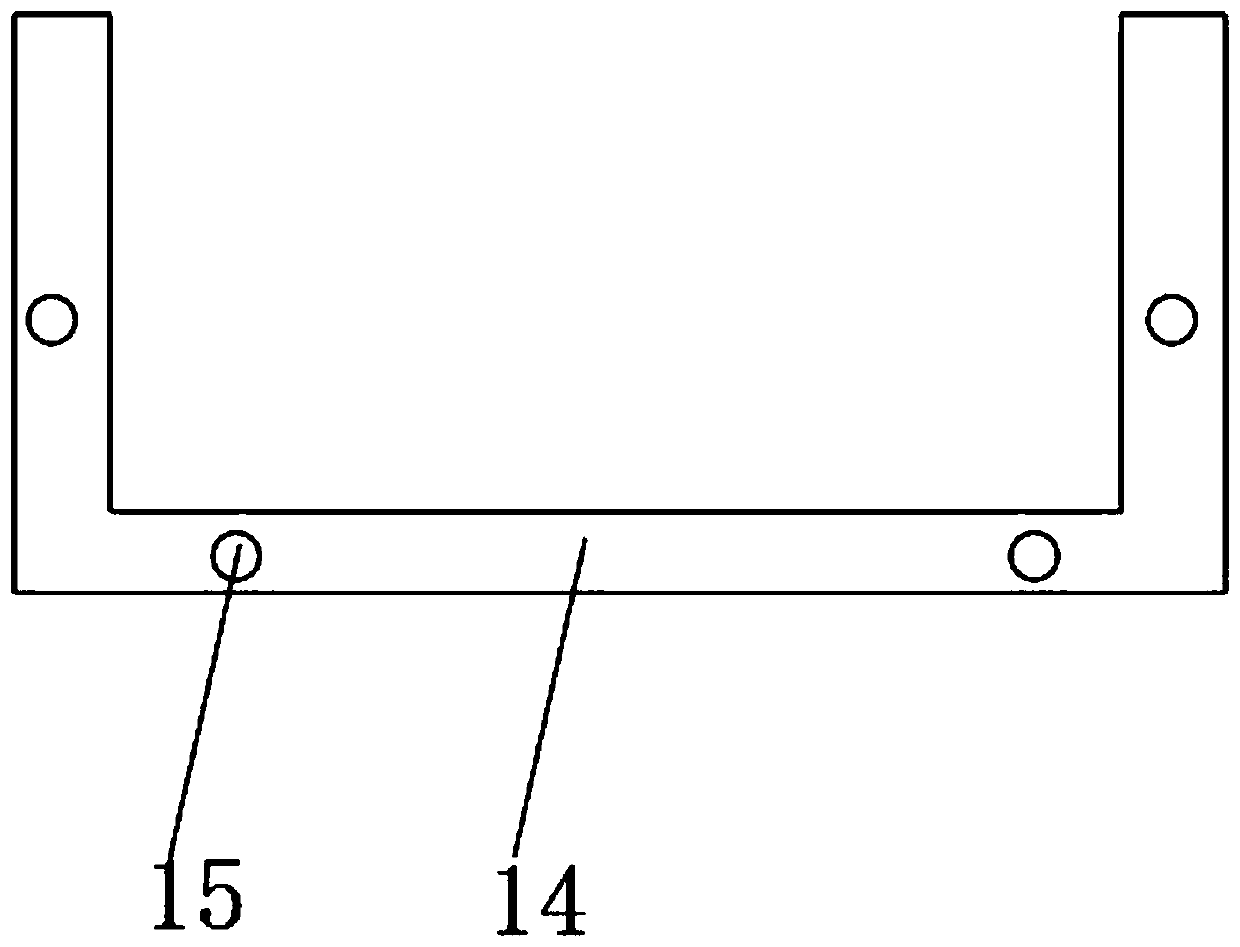

[0031] see Figure 1-6 As shown, an alloy smelting furnace slag removal device includes an installation frame 1 and a rotating shaft 18, the top of the installation frame 1 is welded with a horizontal plate, and the top of the horizontal plate is rotatably installed with a vertically arranged first hydraulic column 8. The top of a hydraulic column 8 is connected with a top plate 9, the top of the top plate 9 is connected with a second hydraulic column 10 inclined downward, the bottom of the second hydraulic column 10 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com