Product detection production line

A production line and product technology, applied in the field of transmission lines, can solve the problems of errors, inaccurate inspection of products, lack of experience of new workers, etc., to achieve the effect of improving work efficiency, saving labor costs, and reducing technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

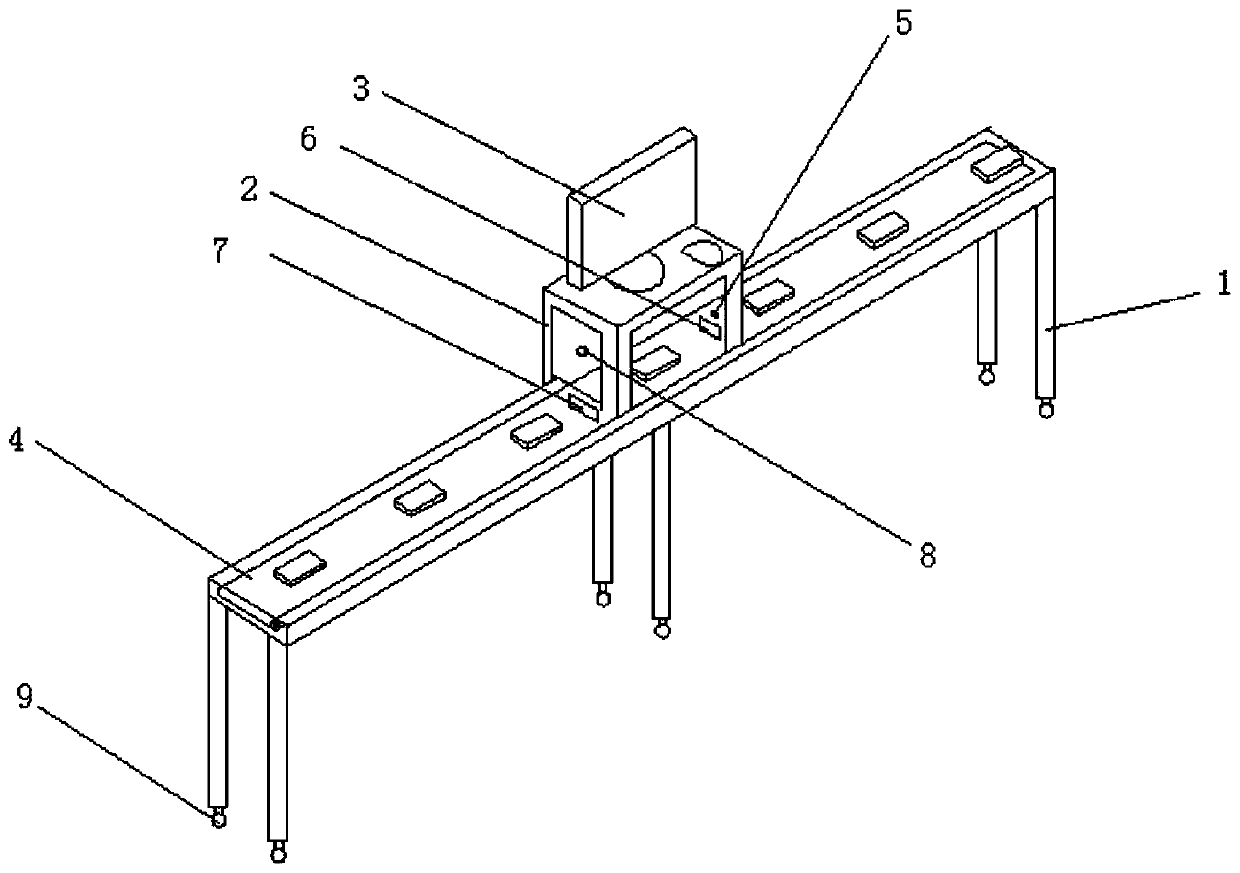

[0011] A product inspection production line, comprising a bracket 1, a detection box 2, and a computer. The bracket is provided with a conveyor belt 4. The detection box 2 is located above the conveyor belt 4 and fixed with the bracket 1. The detection box 2 is equipped with an image system 5, The first sensor 6 and the imaging system 5 are respectively connected with the first sensor 6 and the computer, and the second sensor 7 is also arranged on the support, and the second sensor 7 is connected with the computer.

[0012] Further, an alarm 8 is also provided, and the alarm 8 is connected with the second sensor 7 .

[0013] Further, the computer includes a display 3 installed on the upper surface of the detection box 2 .

[0014] Further, the support 1 is composed of two cross bars parallel to each other and six support legs, the support legs are respectively connected to the two ends and the middle of the cross bar, and the grounding ends of the support legs are provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com