Cooling device used for manufacturing plastic product

A technology for cooling devices and products, applied in the field of cooling devices used in the manufacture of plastic products, can solve the problems of difficult water temperature control, product quality decline, easy agglomeration of particles, etc., and achieve the effect of avoiding excessive temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0025] Example 1

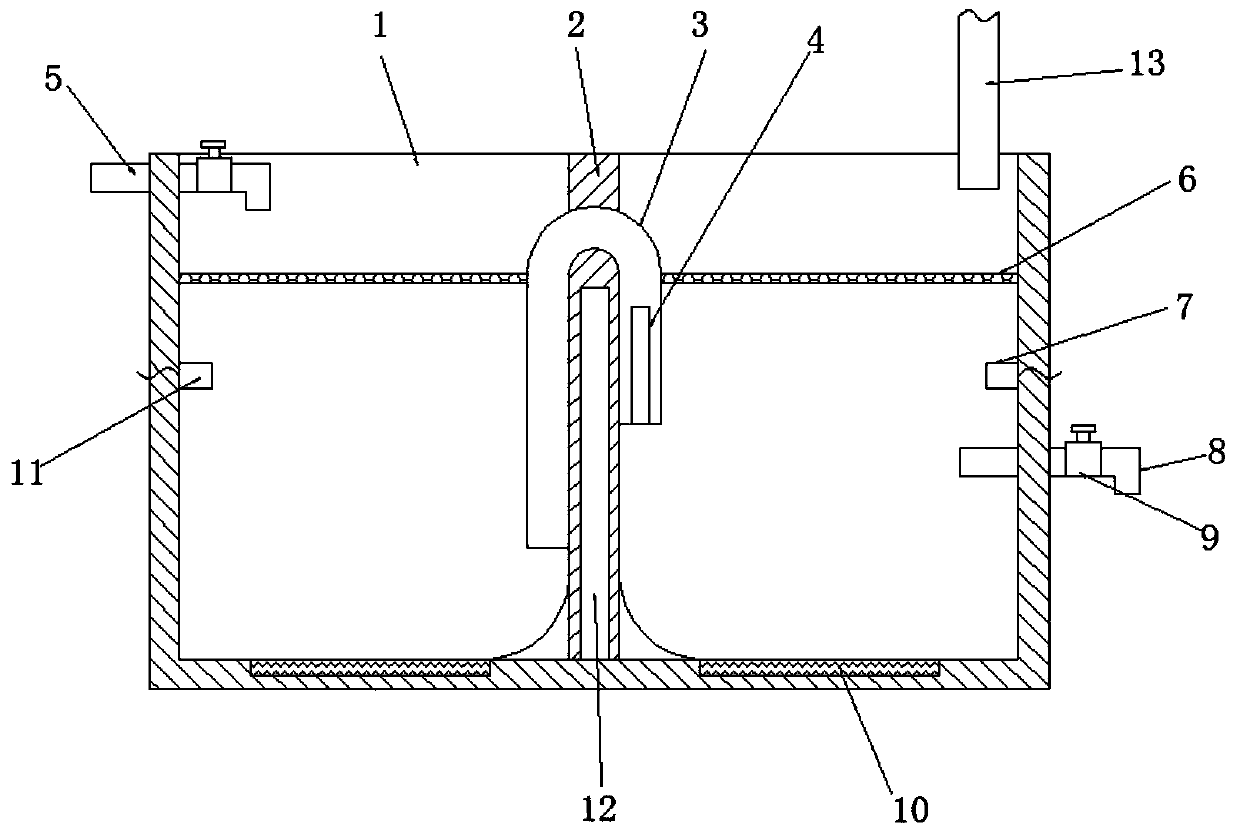

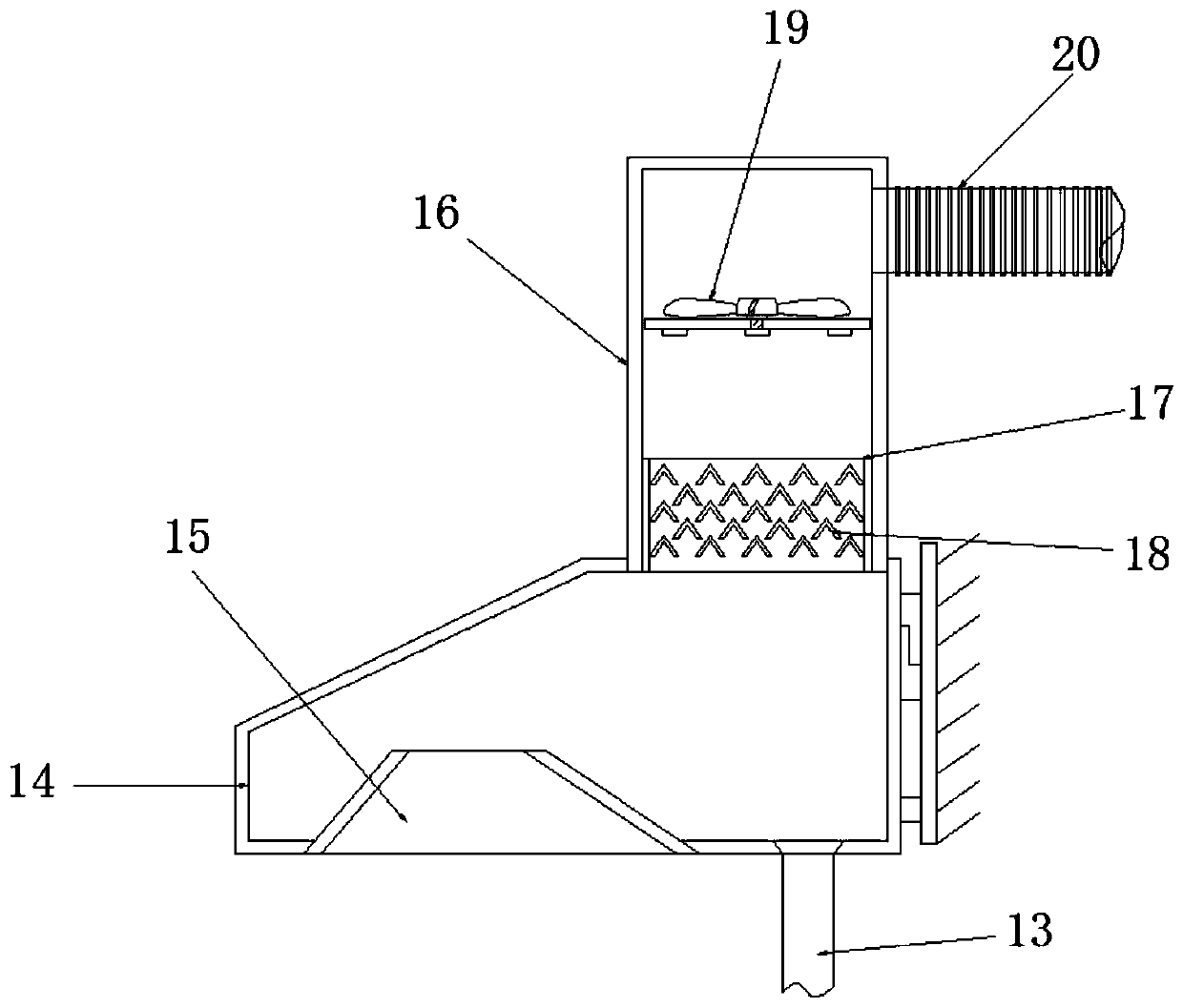

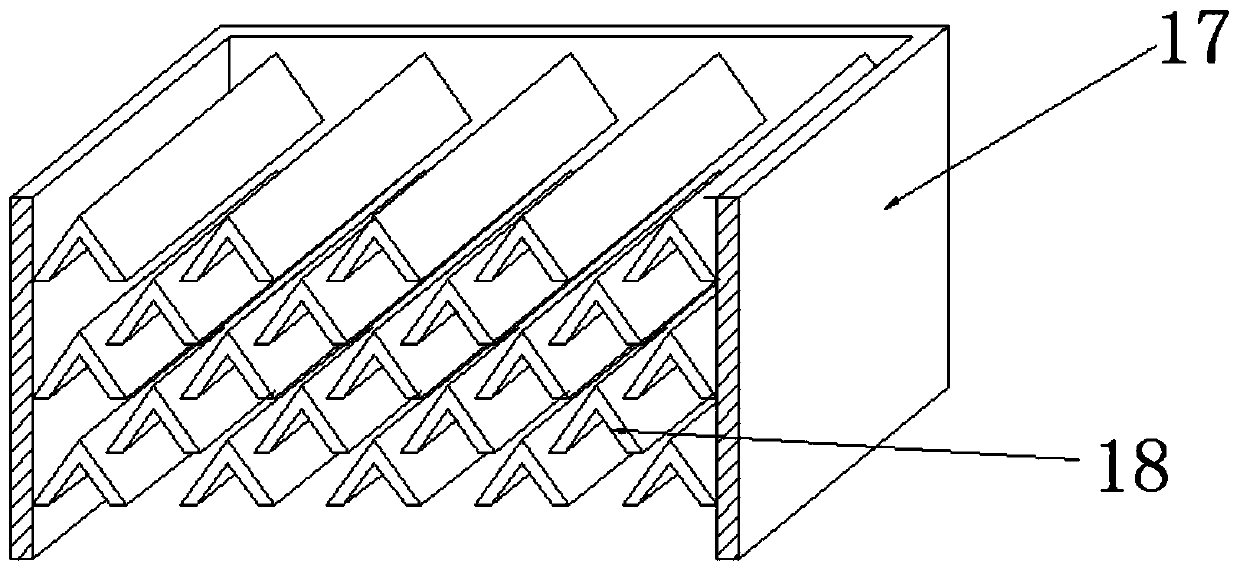

[0026] Reference Figure 1-3 , A cooling device for the manufacture of plastic products, comprising a water tank 1, a partition 2 is fixed in the water tank 1, and the partition 2 divides the interior of the water tank 1 into two water storage chambers, and the partition 2 is fixedly installed with a connecting The two ends of the pipe 3 and the connecting pipe 3 are respectively located in the two water storage chambers. The water outlet on the right side of the connecting pipe 3 is higher than the water inlet on the left side, and the outer wall of the water outlet on the right side of the connecting pipe 3 has a strip hole. 4. The heating plate 10 is fixed on the inner wall of the bottom of the two water storage chambers, and the first temperature sensor 7 and the second temperature sensor 11 are respectively provided on the side walls of the two water storage chambers, and the two water storage chambers are respectively fixedly inserted A water inlet pipe ...

Example Embodiment

[0030] Example 2

[0031] Reference Figure 4 , A cooling device used in the manufacture of plastic products. The difference between this embodiment and embodiment 1 is that symmetrically distributed motors 21 are fixed on the outer walls of both sides of the water tank 1, and the output shaft of the motor 21 passes through the inner wall of the water storage chamber and is fixed with a transmission At one end of the shaft 22 and the transmission shaft 22 away from the motor 21, a plurality of annularly distributed turbine blades 23 are fixed, and arc plates 24 are fixed on both sides of the bottom end of the partition plate 2.

[0032] The working principle of this embodiment: the arrangement of the turbine blades 23 can push the aqueous solution in the left and right water storage chambers under the drive of the motor 21, and the water flow is guided by the arc plate 24 to form the inner parts of the two water storage chambers. Water circulation to prevent the cold water from bei...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap