Independent air feeder for air jet loom

An air-jet loom and air supply device technology, applied in looms, textiles, textiles and papermaking, etc., can solve the problems of high energy consumption, unstable air supply, large construction investment, etc., achieve low energy consumption, ensure normal, The effect of less capital investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

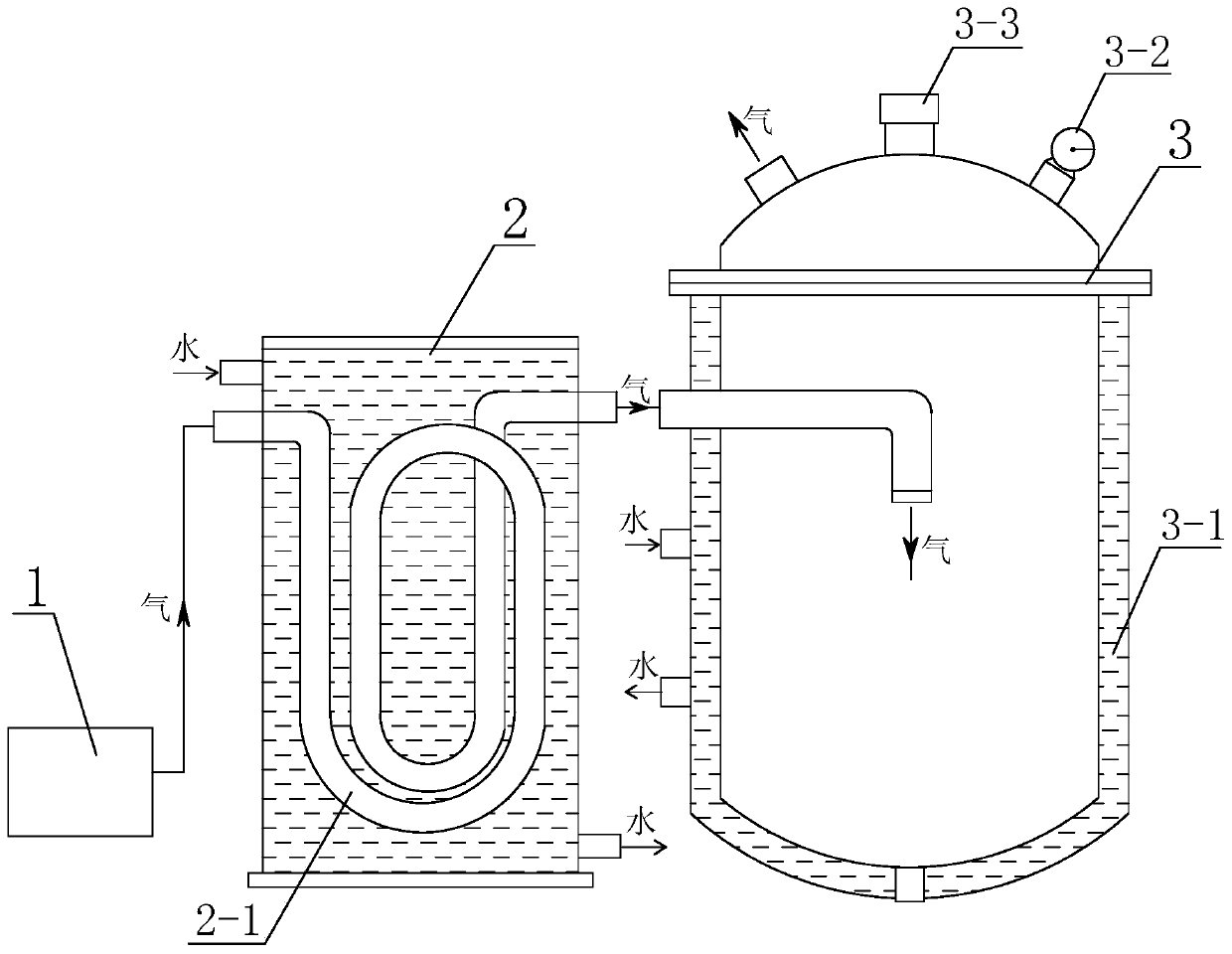

[0013] An independent air supply device for air jet looms, such as figure 1 As shown, it includes a water-cooled air compressor 1, a circulating water cooler 2 and an independent air bag 3. The circulating water cooler 2 has a tank with a water inlet and a water outlet, and an airway plate is arranged in the tank Tube 2-1, the air inlet and outlet of the air duct coil 2-1 are located outside the tank, the air outlet of the water-cooled air compressor 1 is connected with the air inlet of the air duct coil 2-1, The independent air bag 3 has an air tank with an air inlet and an air outlet. The outer wall of the air tank is provided with a water jacket 3-1 with a water inlet and a water outlet. The air outlet of the air duct coil 2-1 and the independent The air inlet of the air tank of the air bag 3 communicates with each other.

[0014] The air tank of the independent air bag 3 is composed of a tank body and a tank cover. The air inlet of the air tank is arranged on the tank body, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap