Water-cooled laser coupler

A coupler and water cooling technology, applied in the coupling of optical waveguides, light guides, optics, etc., can solve problems such as failures and heat accumulation of laser couplers, and achieve the effect of ensuring ease of use, low cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the objectives, technical solutions and advantages of the present invention more clearly understood, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

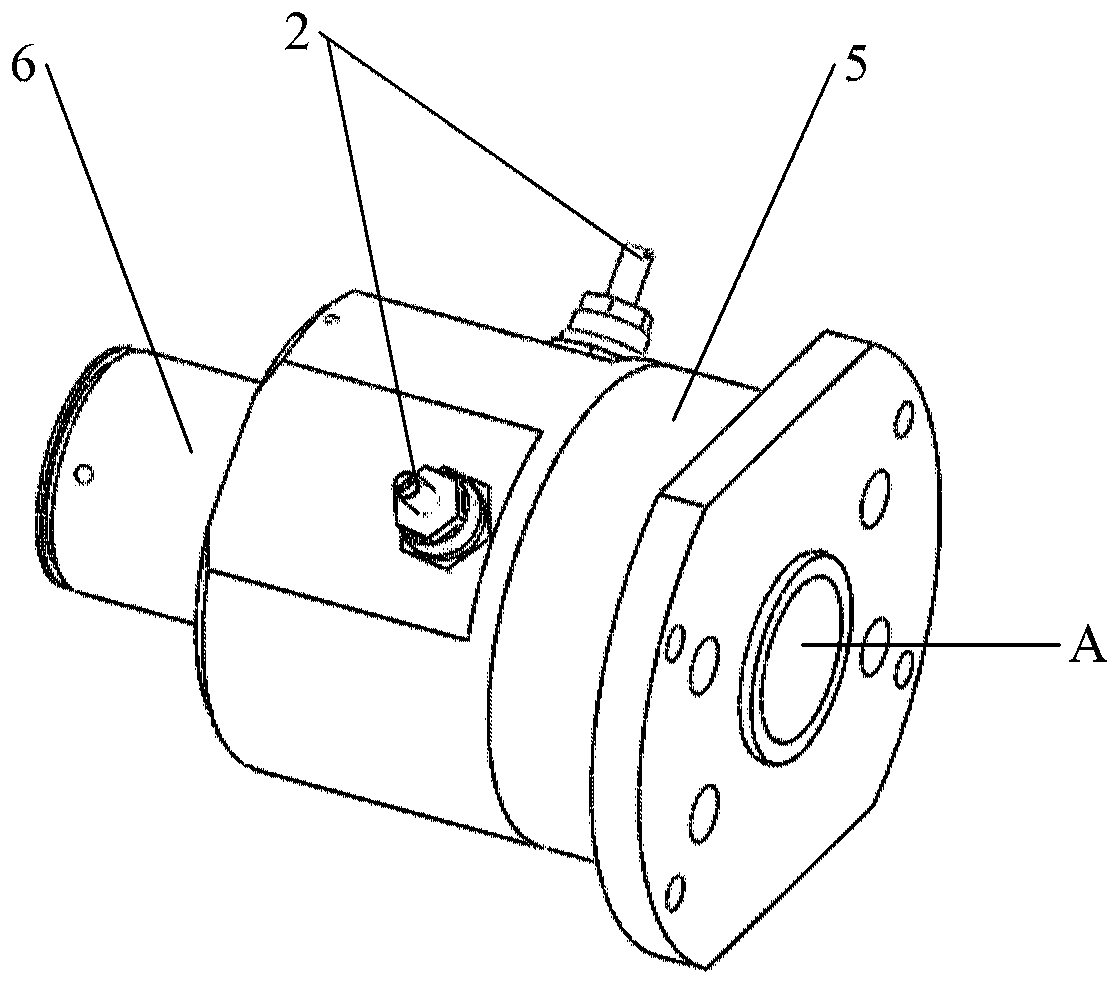

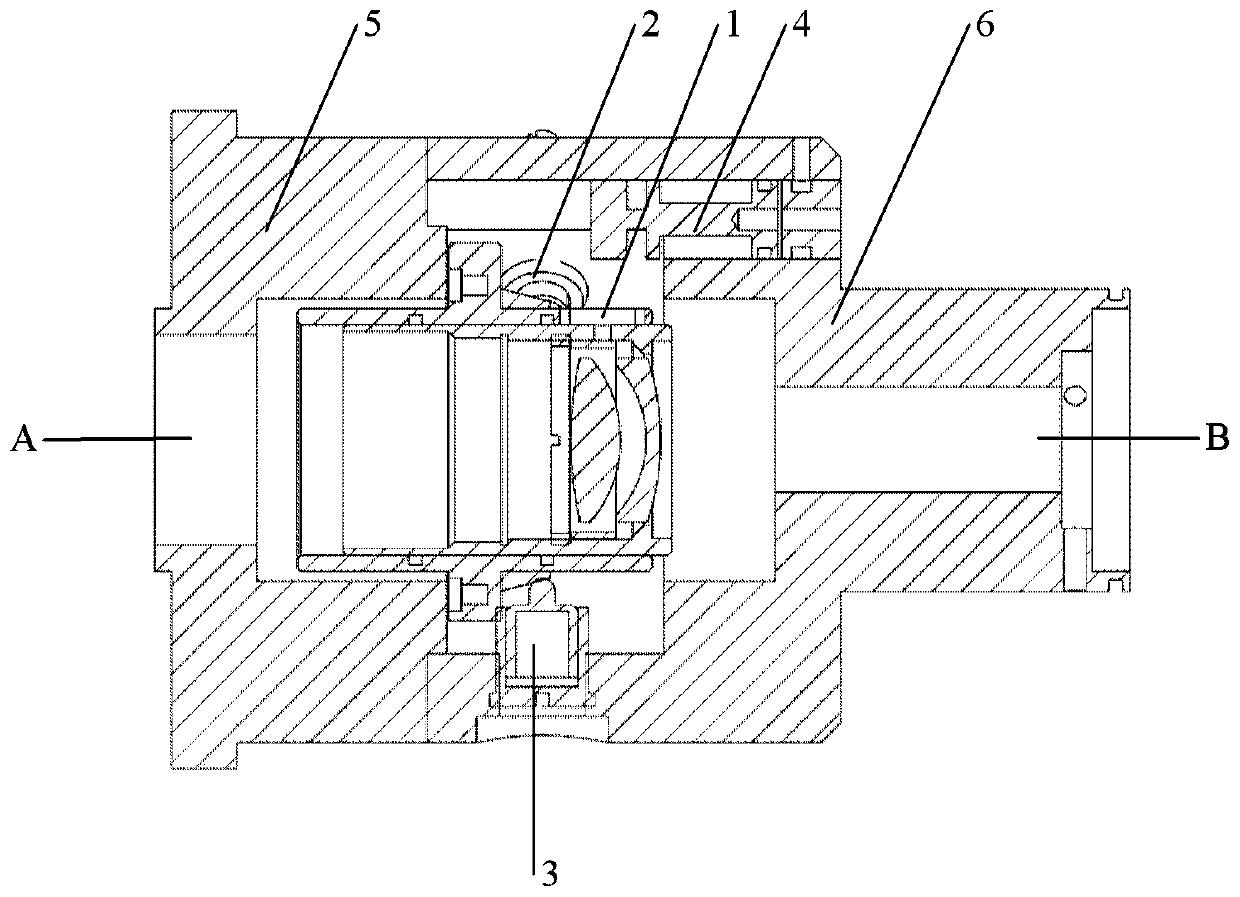

[0037] The first embodiment of the present invention provides a water-cooled laser coupler, specifically, including:

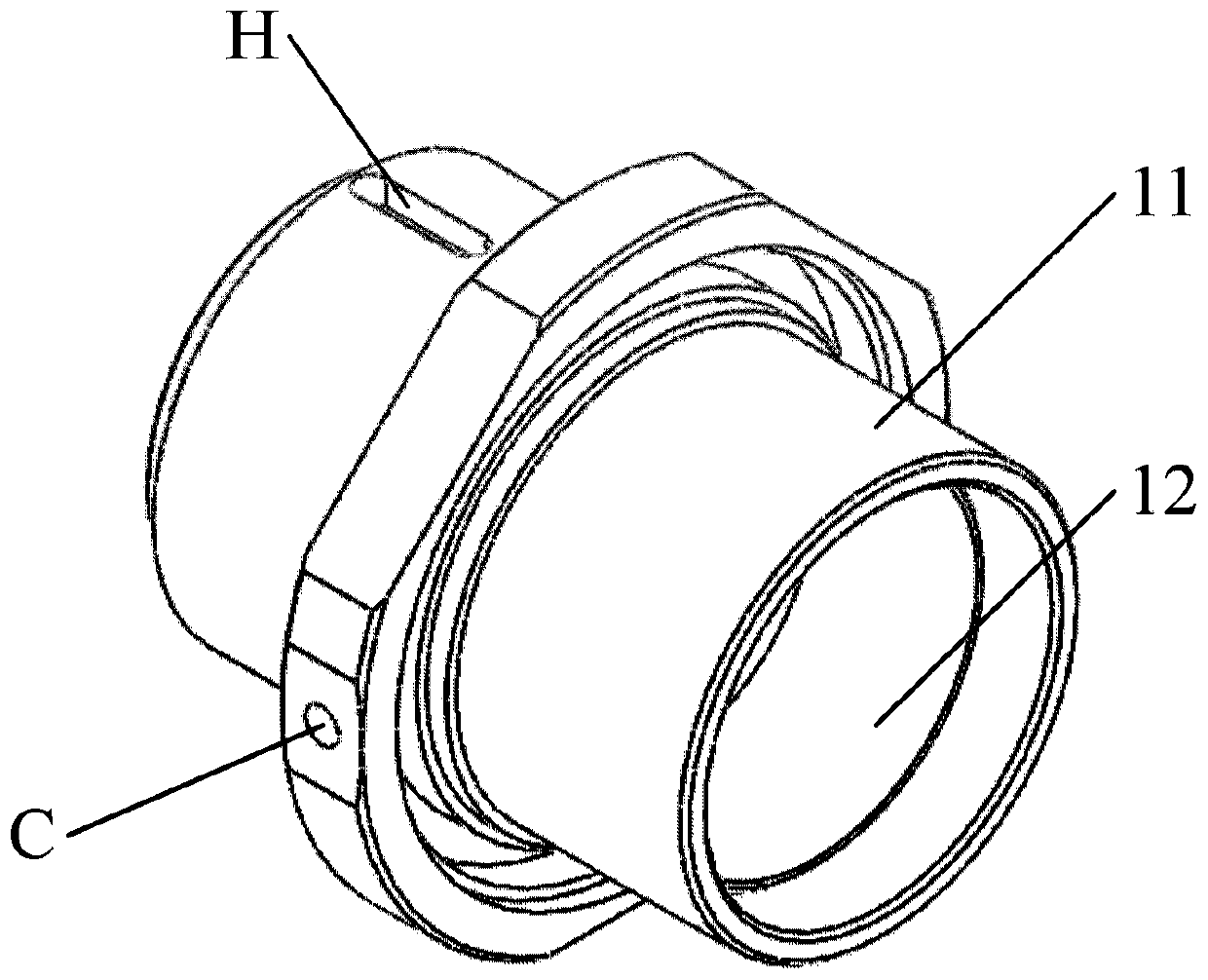

[0038] The water-cooled coupling lens group installation cylinder further comprises: an outer cylinder, which has a water channel, and the water channel is connected to the chiller; and an inner cylinder, which is slidably combined with the outer cylinder.

[0039] In this embodiment, the cooling function is realized by an external chiller, which solves the problem of heat dissipation of the laser coupler when working with high power.

[0040] Based on the above-mentioned water-cooled laser coupler, the second embodiment of the present invention is provided with a differential adjustm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com