Material cabin vacuumizing sealing packaging device of purification device

A sealing and vacuuming technology, used in packaging sealing/fastening, packaging, transportation packaging, etc., can solve the problems of air packaging failure, large differences in tube wall thickness, easy to burn through holes, etc., to ensure consistent size , to avoid adverse effects, the effect of uniform shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0023] Example 1

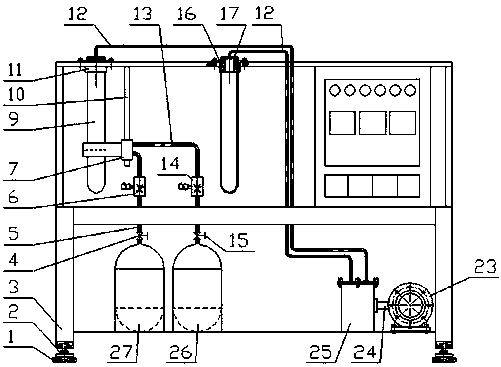

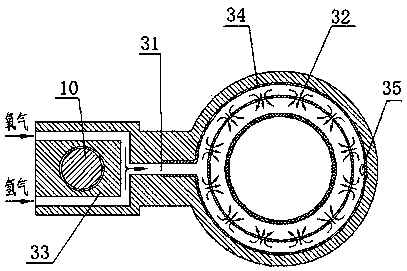

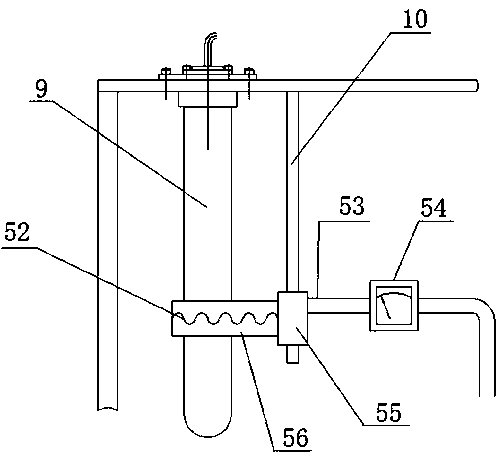

[0024] like figure 1 As shown in the figure, the vacuum sealing and sealing device for the material chamber of the purification device includes a bracket 3, a heating device, a support seat 11, a vacuum tube 12, a sealing ring 16, a transition seat 17, a vacuum air pump 23, and a vacuum barrel 25. The bracket 3. There are at least two through holes on the top, and each through hole is provided with a support seat 11 for installing the material compartment 9. The support seat 11 is provided with a sealing ring 16 for sealing the bottle opening of the material compartment 9, and the transition seat 17 and the support The seat 11 is detachably and fixedly connected to realize the fixing of the sealing ring 16. The middle of the support seat 11 is provided with a vacuum tube 12, and the vacuum tube 12 is connected with the vacuum air pump 23 fixedly installed on the bracket 3. The vacuum air pump 23 is fixedly installed on the The vacuum pump 23 on the support ...

Example Embodiment

[0031] Example 2

[0032] like figure 1As shown in the figure, the vacuum sealing and sealing device for the material chamber of the purification device includes a bracket 3, a heating device, a support seat 11, a vacuum tube 12, a sealing ring 16, a transition seat 17, a vacuum air pump 23, and a vacuum barrel 25. The bracket 3. There are at least two through holes on the top, and each through hole is provided with a support seat 11 for installing the material compartment 9. The support seat 11 is provided with a sealing ring 16 for sealing the bottle opening of the material compartment 9, and the transition seat 17 and the support The seat 11 is detachably and fixedly connected to realize the fixing of the sealing ring 16. The middle of the support seat 11 is provided with a vacuum tube 12, and the vacuum tube 12 is connected with the vacuum air pump 23 fixedly installed on the bracket 3. The vacuum air pump 23 is fixedly installed on the The vacuum pump 23 on the support 3...

Example Embodiment

[0036] Example 3

[0037] On the basis of Embodiment 1 or Embodiment 2, the sealing device can also Figure 4 , Figure 5 The material compartment shown is heated encapsulated as Image 6 As shown, the material cabin is placed on the bracket 3, so that the vacuum tube 12 passes through the support base 11 and then protrudes downward, which can be connected with the packaging port I41 or the packaging port II42 of the two structural material cabins, and then the two different The material cabin is evacuated, and then the sealing port I41 or the sealing port II42 is heated by the heating device. The sealing port I41 or the sealing port II42 becomes soft and glued together after being heated to realize the packaging of the two material cabins.

[0038] In the present invention, the material cabin is evacuated by a vacuum pump; then, the material cabin is heated by a heating device, so that the material cabin is softened and shrunk, and vacuum packaging is completed. The invent...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap