Automobile steel ring trimming device

A technology for steel rings and automobiles, applied in the direction of feeding devices, positioning devices, storage devices, etc., can solve the problems of poor repair accuracy, pulling deformation, and excessive reset of steel rings, so as to avoid secondary damage, avoid excessive reset, and reset accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

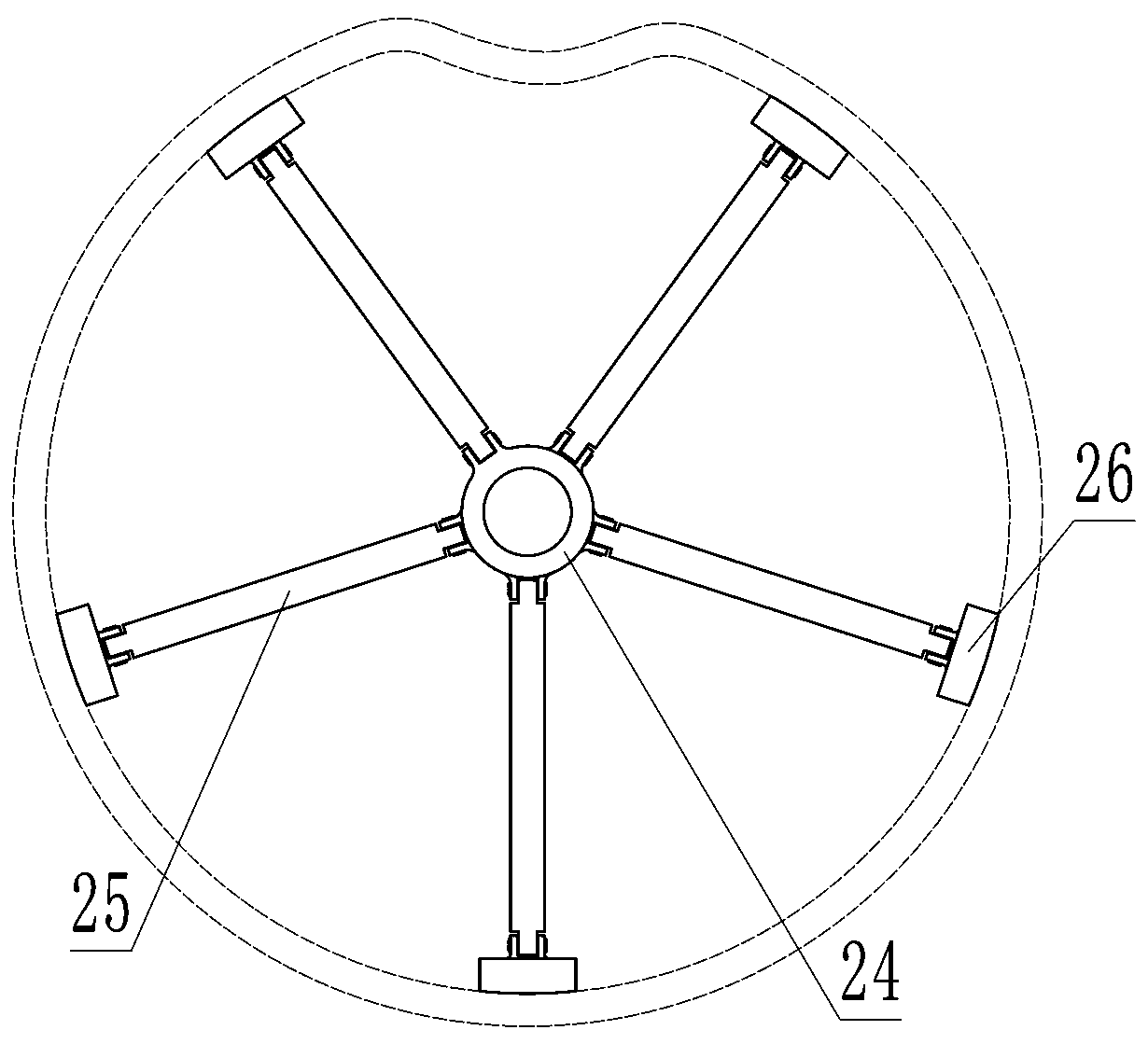

[0015] by Figure 1 to Figure 8 Given that the present invention includes a horizontal shaft 1 for fixing the steel ring, a support unit that can be installed on the horizontal shaft 1, and a reset hydraulic cylinder. The reset hydraulic cylinder includes a base 2, an inner cylinder 3, and an outer cover 4. The inner cylinder 3 is two The inner cylinder 3 and the outer cover 4 are vertically and coaxially installed on the base 2. The upper and lower ends of the inner cylinder 3 are respectively pressed against the top wall of the base 2, the outer cover 4, and the inner cylinder 3 and the outer cover 4 An interlayer 5 is formed in between. The interlayer 5 is filled with hydraulic oil that can fill the inner cylinder 3. The base 2 is provided with an oil inlet channel 6 and an oil return control unit connecting the interlayer 5 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com