Large-diameter titanium alloy seamless pipe and its preparation method

A seamless pipe and titanium alloy technology, applied in the field of large-diameter titanium alloy seamless pipe and its preparation, can solve the problems of high production cost, limited application of alloy pipe, immature rolling process, etc., and achieve low cost of production equipment , Simple and controllable two-phase zone deformation, deformation temperature are easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

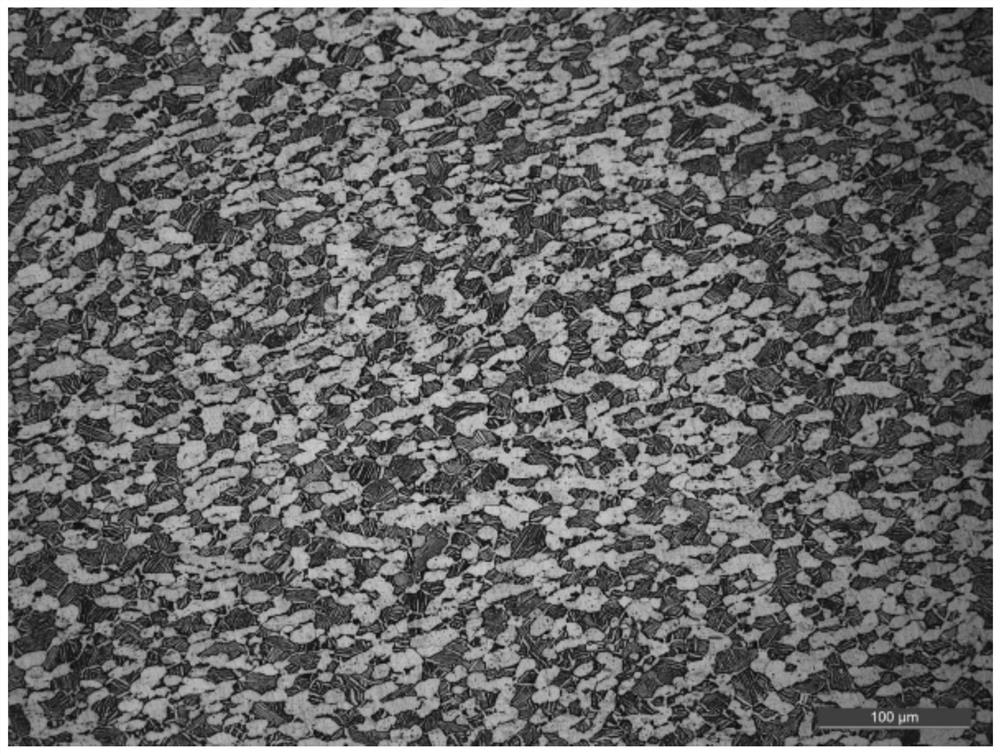

Image

Examples

preparation example Construction

[0032] One embodiment of the present invention provides a method for preparing a large-diameter titanium alloy seamless pipe. The process route is: billet forging → dynamic recrystallization heat treatment processing → forging processing below the β transformation temperature → billet making → mandrel drawing below the β transformation temperature And hole expansion → roll forming below the β transition temperature, specifically including the following steps 1 to 5.

[0033] Step 1), using a titanium alloy ingot of Φ660 mm to Φ780 mm as a billet to carry out billet forging.

[0034] One step further, the titanium alloy ingot is Ti75 alloy ingot.

[0035] Further, the titanium alloy ingot is a Φ780mm Ti75 alloy ingot.

[0036] Further, the step of billet forging is to perform 1-2 times of upsetting forging on the titanium alloy ingot at a temperature of 100° C. to 250° C. above the β transformation temperature of the titanium alloy ingot.

[0037] The coarse as-cast structure...

Embodiment 1

[0064] Example 1: Preparation of a Ti75 alloy seamless pipe with a specification of Φ680mm

[0065] 1), blank forging

[0066] The Φ780mm Ti75 alloy ingot with a β transformation temperature of 945°C was used as the raw material for 2 times of upsetting and drawing forging.

[0067] Among them, the temperature of 1-fire forging is 1150°C, two upsetting and two drawing forging to □620mm ("□620mm" means "a square ingot with a side length of 620mm), the forging ratio is 6.25, and air cooling is used after forging; the temperature of 2-fire forging The temperature is 1100℃, forging to □620mm with one upsetting and one drawing, the forging ratio is 2.5, and air cooling is used after forging.

[0068] 2), dynamic recrystallization heat treatment

[0069] Carry out double upsetting and two drawing forging to □620mm for the blank processed in step 1), the forging temperature is 915°C, and the forging ratio is controlled at 6.0; after forging, it is directly returned to the furnace f...

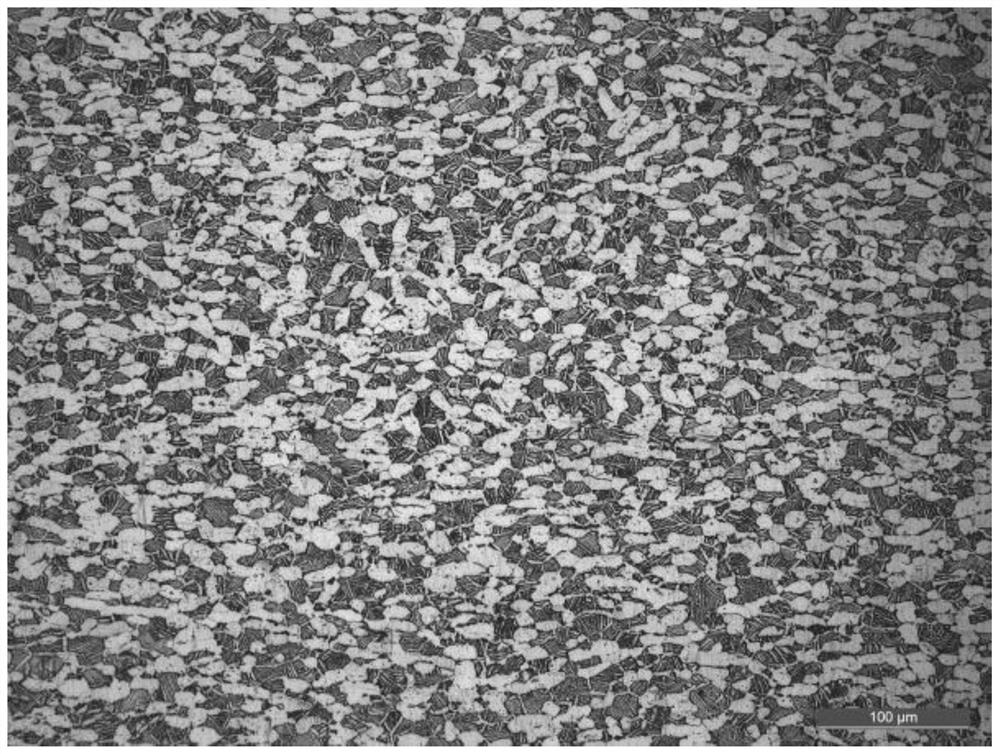

Embodiment 2

[0081] Example 2: Preparation of Ti75 alloy seamless pipe with a specification of Φ600mm

[0082] 1), blank forging

[0083] A Φ780mm Ti75 alloy ingot with a β transformation temperature of 950°C was used for two times of upsetting and drawing forging.

[0084] Among them, the temperature of 1-fire forging is 1150℃, two upsetting and two drawing forging to □620mm, the forging ratio is 6.25, and air cooling is used after forging; 2.5, air cooling is used after forging.

[0085] 2), dynamic recrystallization heat treatment

[0086] Carry out double upsetting and two drawing forging to □620mm for the blank processed in step 1), the forging temperature is 920°C, and the forging ratio is controlled at 6.0; after forging, it is directly returned to the furnace for recrystallization heat treatment, the recrystallization heat treatment temperature is 1040°C, and the heat preservation After 300 minutes, it was released from the furnace, and then forged with one upsetting and one dra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com