Water-based dip-coating graphene air-drying coating and preparation method thereof

A self-drying coating and graphene technology, applied in anti-corrosion coatings, coatings, etc., can solve problems such as poor water resistance, salt spray resistance time, limiting the development of water-based coatings, and difficult anti-corrosion performance, achieving improved scratch resistance. Anti-sedimentation performance, effect of improving anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

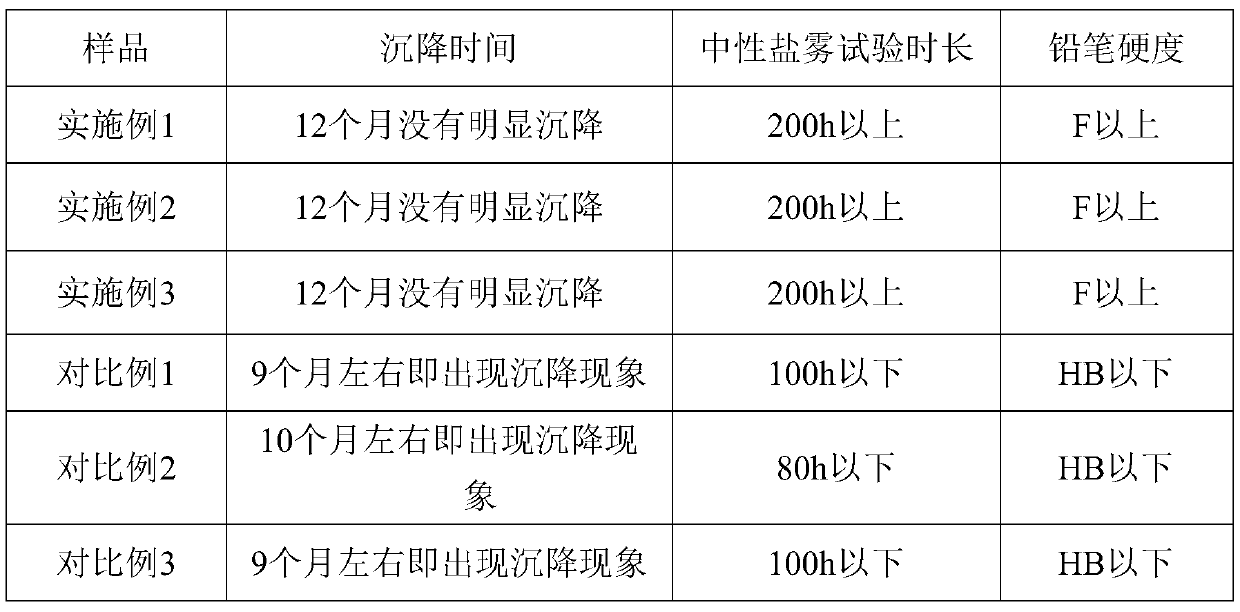

Examples

Embodiment 1

[0033] A water-based dip coating graphene self-drying coating, the water-based self-drying coating is: styrene-acrylic emulsion 56.5%, alcohol ether film-forming aid 9.5%, polysiloxane defoamer 1.0%, acrylic acid Leveling agent 1.0%, unsaturated polycarboxylic acid polymer 1.0%, graphene 5.0%, epoxy silane modified pigment 2.0%, acetylenic alcohol-based water-based metal slow-release anti-flash rust agent 2.0%, polyacrylic acid enhancer Thickener 2.0%, water 20.0%.

[0034] A kind of preparation method of aqueous dip coating graphene self-drying coating, comprises the steps:

[0035] (1) Premix unsaturated polycarboxylic acid polymer, polysiloxane defoamer, alcohol ether film-forming aid with water, and then add graphene to high-speed dispersion pulping;

[0036] (2) Grinding the slurry obtained in step (1) through a sand mill to a fineness below 15 μm;

[0037] (3) The slurry obtained in step (2) and other additives are added to the styrene-acrylic emulsion under stirring t...

Embodiment 2

[0042] A water-based dip coating graphene self-drying coating, the water-based self-drying coating is: styrene-acrylic emulsion 66.0%, alcohol ester twelve film-forming aids 6.8%, polyether defoamer 0.5%, fluorocarbon 0.7% leveling agent, 0.4% modified acrylic block copolymer, 2.8% graphene, 0.8% epoxy silane modified pigment, 1.7% acetylenic alcohol-based water-based metal slow-release anti-flash rust agent, polyurethane thickener Thickener 0.8%, water 19.5%.

[0043] A kind of preparation method of aqueous dip coating graphene self-drying coating, comprises the steps:

[0044] (1) Premix the modified acrylic acid block copolymer, polyether defoamer, alcohol ester twelve film-forming aids with water, and then add graphene for high-speed dispersion pulping;

[0045] (2) Grinding the slurry obtained in step (1) through a sand mill to a fineness below 15 μm;

[0046] (3) The slurry obtained in step (2) and other additives are added to the styrene-acrylic emulsion under stirrin...

Embodiment 3

[0051] A water-based dip-coating graphene self-drying coating, the water-based self-drying coating is: 70.0% of styrene-acrylic emulsion, 2.2% of alcohol ether film-forming aids, 0.4% of polyether modified polysiloxane defoamer according to mass percentage %, silicone leveling agent 0.5%, modified acrylic block copolymer 0.8%, graphene 4.0%, epoxy silane modified pigment 2.5%, acetylenic alcohol-based water-based metal slow-release anti-flash rust agent 0.9% , Polyoxyethylene thickener 1.5%, water 17.2%.

[0052] A kind of preparation method of aqueous dip coating graphene self-drying coating, comprises the steps:

[0053] (1) Premix the modified acrylic block copolymer, polyether-modified polysiloxane defoamer, and alcohol ether film-forming aid with water, and then add graphene for high-speed dispersion and pulping;

[0054] (2) Grinding the slurry obtained in step (1) through a sand mill to a fineness below 15 μm;

[0055] (3) The slurry obtained in step (2) and other add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com