Carbon nanofiber membrane for electromagnetic shielding and resin composite board and preparation methods thereof

A nano-carbon fiber and nano-fiber film technology, which is applied in the field of new material technology and composite materials, can solve problems such as the difficulty of preparing nano-carbon fiber film, and achieve good electromagnetic shielding performance, simple preparation method, and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

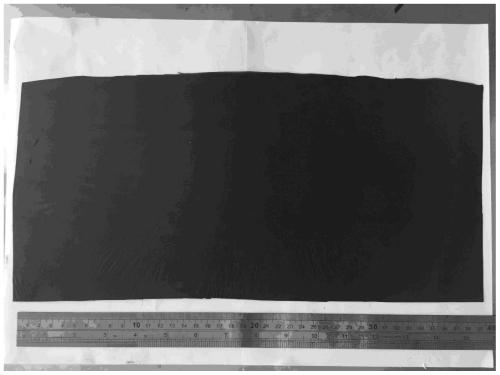

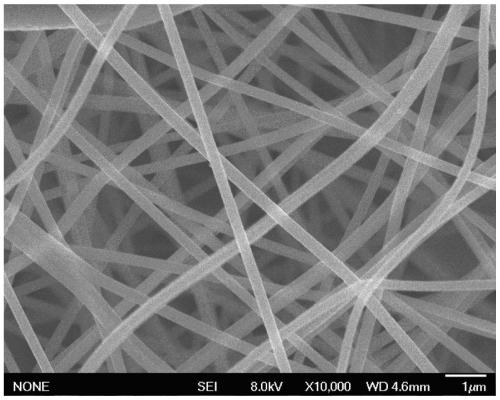

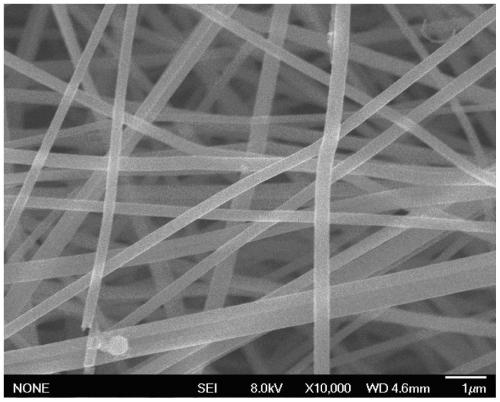

[0029] Embodiment 1: the PAN powder of 6g is dissolved in the DMF of 50mL and the preparation concentration is the PAN solution of 12%, the PAN solution is packed in the injector, the setting spinning distance is 15cm, and the injection speed is 2.5mL / h, The spinning voltage was 15kV, and the PAN nanofiber film was prepared by electrospinning; the PAN nanofiber film was placed in a pre-oxidation furnace, and the pre-oxidation temperature was set to 260°C, and the time was 120min, and the PAN pre-oxidation film was obtained by pre-oxidation; The PAN pre-oxidized film is placed in a carbonization furnace, and the carbonization temperature is set to 1400°C, and the time is 120min, and carbonized to obtain a carbonized film; the carbonized film is placed in a graphitization furnace, and the set temperature is 2400°C, and the time is 120min, and graphitization is performed treatment to obtain the carbon nanofiber film for electromagnetic shielding, figure 1 It is an optical photogr...

Embodiment 2

[0031]Embodiment 2: This embodiment is basically the same as Embodiment 1, the differences are: the concentration of PAN solution is 5%, the voltage is 15kV, the spinning distance is 18cm, the pre-oxidation temperature is 250°C, the pre-oxidation time is 3h, and the carbonization temperature 1000°C, carbonization time is 3h, graphitization temperature is 2000°C, graphitization time is 3h, heating temperature for surface oxidation treatment is 350°C, heating time is 30min, applied pressure is 1.2MPa, curing temperature is 100°C, curing The time is 30 minutes.

[0032] The tensile strength of the resin composite plate prepared in this embodiment is 62.5MPa, and the electromagnetic shielding effectiveness in the range of 30MHz-5GHz is about 28dB.

Embodiment 3

[0033] Embodiment 3: This embodiment is basically consistent with Embodiment 1, the differences are: the concentration of PAN solution is 15%, the voltage is 12kV, the spinning distance is 10cm, the pre-oxidation temperature is 300°C, the pre-oxidation time is 1h, and the carbonization temperature The temperature is 1400°C, the carbonization time is 1h, the graphitization temperature is 2400°C, the graphitization time is 1h, the heating temperature for surface oxidation treatment is 450°C, the heating time is 30min, the applied pressure is 0.8MPa, and the curing temperature is 70°C. The time is 60 minutes.

[0034] The tensile strength of the resin composite plate prepared in this embodiment is 67.5MPa, and the electromagnetic shielding effectiveness in the range of 30MHz-5GHz is about 28dB.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Electromagnetic shielding effectiveness | aaaaa | aaaaa |

| Electromagnetic shielding effectiveness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com