A kind of additive and working fluid for preventing epoxy resin-based downhole working fluid solid phase particle sedimentation

A technology of epoxy resin and solid epoxy resin, applied in the direction of drilling compositions, chemical instruments and methods, etc., to achieve the effect of saving operating time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

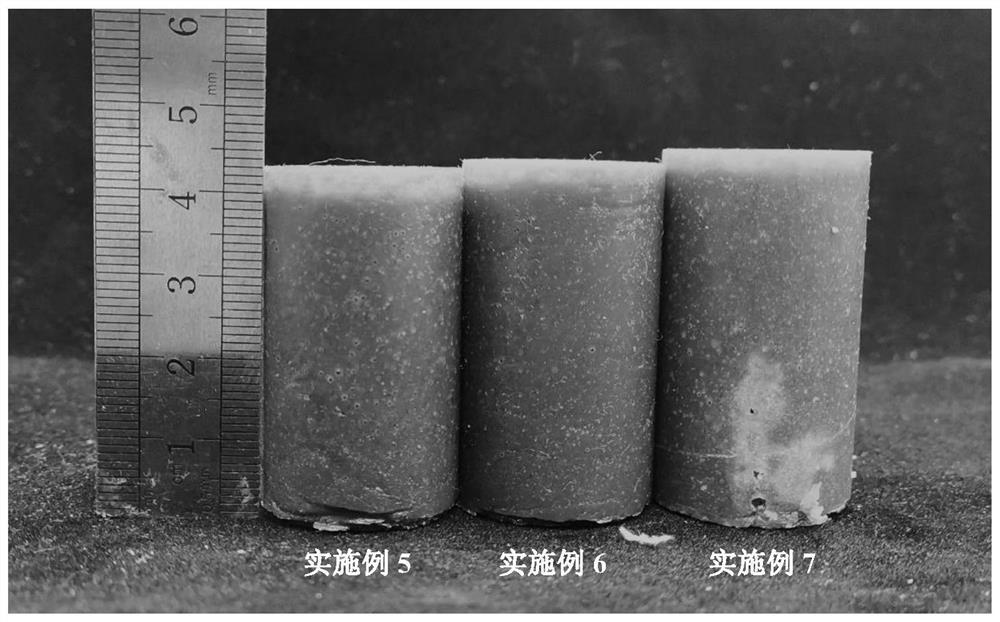

Embodiment 1

[0038] The epoxy resin base paste is the same as that of Comparative Example 1.

[0039] Anti-settling admixture: 5 parts of E-20 solid epoxy resin.

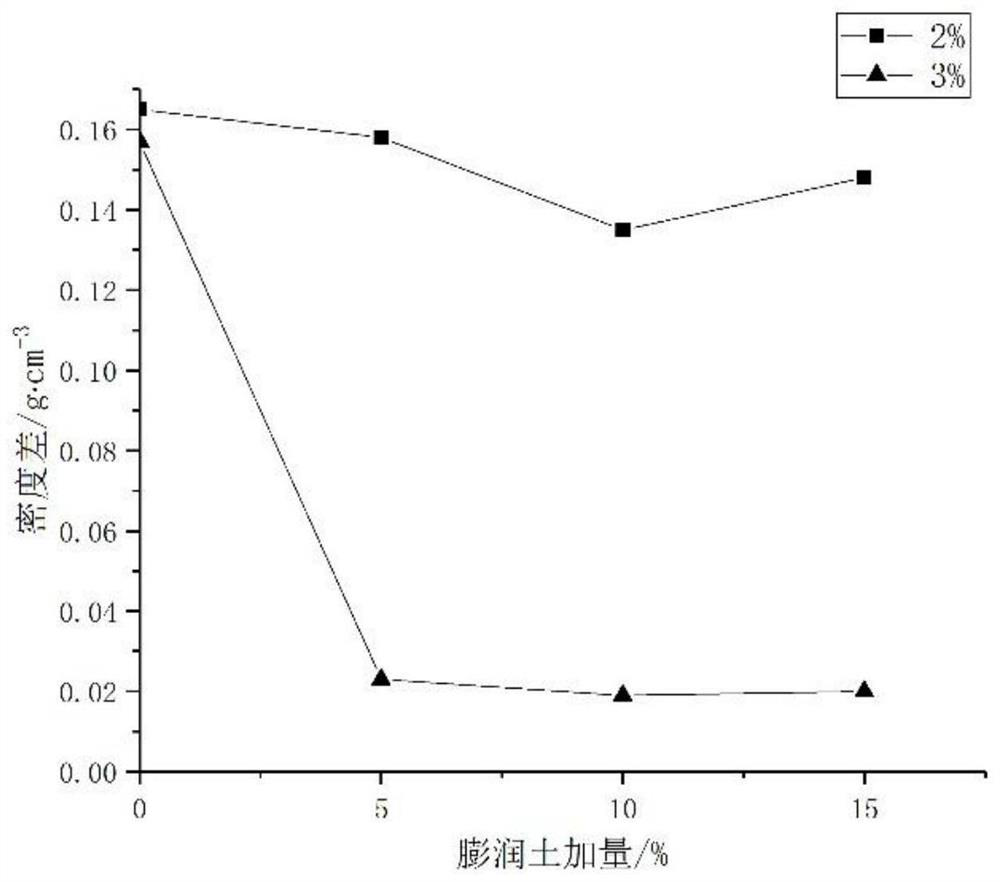

[0040] Preparation method: After mixing E-51 epoxy resin, curing agent and diluent evenly, add E-20 epoxy resin and barite, and prepare slurry according to API 10B-3-2004 oil well cement test method. The experimental results see figure 1 .

Embodiment 2

[0042] The epoxy resin base paste is the same as that of Comparative Example 1.

[0043] Anti-settling admixture: 10 parts of E-20 solid epoxy resin.

[0044] Preparation method: After mixing E-51 epoxy resin, curing agent and diluent evenly, add E-20 epoxy resin and barite, and prepare slurry according to API 10B-3-2004 oil well cement test method. The experimental results see figure 1 .

Embodiment 3

[0046] The epoxy resin base paste is the same as that of Comparative Example 1.

[0047] Anti-settling admixture: 15 parts of E-20 solid epoxy resin.

[0048] Preparation method: After mixing E-51 epoxy resin, curing agent and diluent evenly, add E-20 epoxy resin and barite, and prepare slurry according to API 10B-3-2004 oil well cement test method. The experimental results see figure 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com